Mtundu wa mbiya yowomba wononga yomwe ndimasankha imakhudza kwambiri njira zowomba, makamaka pogwiritsa ntchito aPC kuwomba botolo makina. A bwino osankhidwakuwomba akamaumba screw mbiyakumathandizira kupanga bwino pomwe kumachepetsa ziwopsezo zotsalira. Kuyanjanitsa chisankho changa ndi zofunikira zopangira zimatsimikizira kugwira ntchito bwino, makamaka pamakina ogwiritsira ntchito ngatiJekeseni Wotambasula Wowomba Makina Omangira.

Chidule cha Migolo Yowomba Screw

Tanthauzo ndi Ntchito

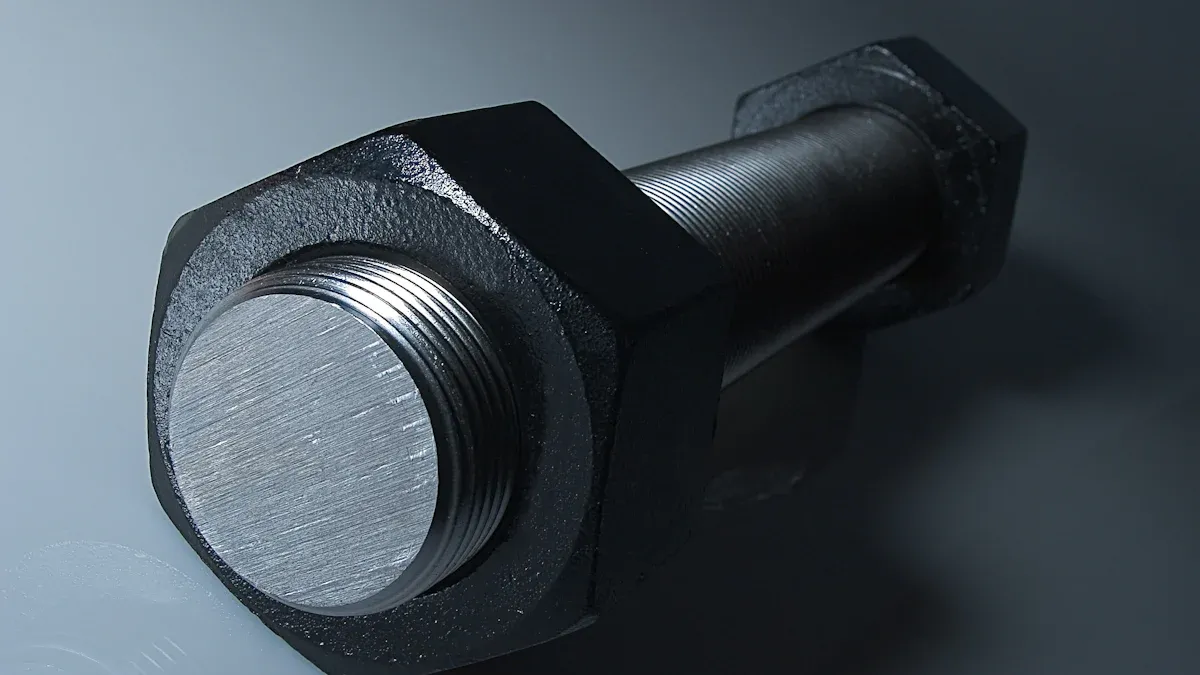

Kuwomba mbiya ya screw ndi chinthu chofunikira kwambiri pakuumba nkhonya. Imakhala ngati ngalande yomwe zida zopangira, zomwe nthawi zambiri zimatchedwa thermoplastics, zimasinthidwa kukhala zinthu zomwe zingagwiritsidwe ntchito. Mapangidwe a screw barrel amakhudza mwachindunji kumeta ubweya pazinthu, zomwe zimakhudza kutentha kwasungunuka. Ubale uwu ndi wofunikira kuti tikwaniritse kukhazikika kwa matchalitchi ndikuchepetsa nthawi yozungulira. Ndapeza kuti kugwiritsa ntchito zomangira zomwe zimapangidwira zinthuzo, monga HDPE kapena PP, kumawonjezera kutulutsa komanso kuchita bwino. Zolinga zapagulu zitha kusokoneza magwiridwe antchito, zomwe zimabweretsa kusakwanira.

Udindo mu Blow Molding

Pakuwomba mbiya, mbiya yowombetsayo imakhala ndi gawo lofunikira pakuwonetsetsa kuti zinthu zizifanana. Zotsatirazizinthu zimathandiza mbali yofunika imeneyi:

| Mbali | Kupereka kwa Material Homogeneity |

|---|---|

| Kuyenda Kwazinthu Zosagwirizana | Zofunikira popanga mabotolo apamwamba okhala ndi ma parison ofananira. |

| Kusintha kwa Melt Homogeneity | Zimatheka kudzera mu helical grooves ndi zomangira zotchinga, kuonetsetsa kuti zimasungunuka. |

| Kusintha Mwamakonda Mapangidwe | Zogwirizana ndi ma resin enieni, kuchepetsa zinyalala ndikuwongolera gawo labwino. |

| Kuwongolera Kutentha | Imasunga kuyenda koyenera kwa zinthu, kuteteza kusungunuka kosafanana ndi kuwonongeka. |

Zomwe zikuchitika muukadaulo wa screw barrel, monga kukula kwa migolo ya bimetallic, kumapangitsa kulimba ndi magwiridwe antchito. Kupita patsogolo kumeneku, limodzi ndi makina otenthetsera ndi kuziziritsa bwino, zimathandizira kuwongolera bwino kutentha panthawi yokonza. Ndawona kuti zatsopanozi zimadzetsa kutsika kwa ndalama zogwirira ntchito komanso kuwongolera kwazinthu, kupanga kusankha koyenera kwa kuwomba mbiya kofunika kwambiri.

Mitundu ya Migolo Yowomba

Migolo ya Single-Screw

Migolo ya sikelo imodzindi m'gulu la mitundu yofala kwambiri yomwe imagwiritsidwa ntchito popanga nkhonya. Ndimayamikira kuphweka kwawo ndi mphamvu zawo pakusungunula ndi kusakaniza zipangizo. Migolo iyi imatsimikizira kuyenda kosasunthika kwa pulasitiki kusungunuka panthawi yopanga, zomwe ndizofunikira kuti zisunge kupanikizika ndi kuyenda. Ndawona kuti ndizothandiza kwambiri m'mafakitale osiyanasiyana, kuphatikiza:

| Makampani | Kufotokozera kwa Ntchito |

|---|---|

| Makampani apulasitiki | Extrusion ndi jekeseni akamaumba mapaipi, mapepala, ndi mbiri. |

| Packaging Viwanda | Mafilimu, mapepala, ndi kuwombera ntchito. |

| Makampani Agalimoto | Kupanga zida zapulasitiki ndi zida zamkati. |

| Makampani Omanga | Kutulutsa mapaipi a PVC, mbiri yazenera, ndi mapepala otsekera. |

| Makampani Obwezeretsanso | Kukonza zinyalala za pulasitiki kukhala ma granules ogwiritsidwanso ntchito. |

Mapangidwe a mbiya imodzi-screw amalola kuti asungunuke bwino, omwe ndi ofunikira kuti apange mankhwala apamwamba opangidwa ndi mphutsi. Ndikuwona kuti zimakhala zogwira mtima kwambiri pogwira ntchito ndi zipangizo monga HDPE ndi PP, monga momwe zimakhalira ndi kayendetsedwe kofunikira pa kusungunuka kwasungunuka.

Migolo ya Twin-Screw

Migolo ya twin-screw imapereka maubwino ochulukirapo kuposa mapangidwe a sikelo imodzi, makamaka pankhani ya kusakaniza ndi kukonza zinthu. Ndadzionera ndekha momwe zomangira zawo zophatikizira zimadzipukuta zokha, zomwe zimapangitsa kuti kusakanizika bwino. Izi zimatsimikizira kubalalitsidwa kokwanira kwa zowonjezera ndi mitundu, zomwe zimatsogolera ku khalidwe lofanana la mankhwala.

| Mbali | Twin-Screw Extruder | Single-Screw Extruder |

|---|---|---|

| Kusakaniza Mwachangu | Kutha kusakanikirana kwakukulu chifukwa cha ma meshing ndi kuzungulira | Kuthekera kosakanikirana kotsika |

| Kukhazikika kwazinthu | Imasunga bata ndi kufananiza panthawi yokonza | Pang'ono khola pa processing |

| Kuthamanga kwa Extrusion | Mofulumira extrusion liwiro | Kuthamanga kwapang'onopang'ono kwa extrusion |

| Kugwiritsa Ntchito Mphamvu | Kugwiritsa ntchito mphamvu zochepa pagawo lililonse | Kugwiritsa ntchito mphamvu kwambiri |

M'machitidwe opangira zotulutsa zotulutsa kwambiri, migolo yamapasa awiri imakhala yabwino kwambiri chifukwa cha kuthekera kwawo kosakanikirana komanso kutulutsa kwakukulu. Ndapeza kuti amatha kuthana ndi zinthu zosiyanasiyana, kuphatikiza ma polima owoneka bwino kwambiri komanso zinthu zosamva kutentha, zomwe zimawapangitsa kukhala osunthika pazinthu zosiyanasiyana.

Migolo ya Barrier-Screw

Migolo ya barrier-screw imagwira ntchito yofunika kwambiri pakuwongolera kusungunuka kwamadzi ndi kupanikizika pakuwumba. Mapangidwe awo amakhala ndi njira zofananira zomwe zimathandizira kutembenuka kwapang'onopang'ono kwa ma pellets olimba kukhala osungunuka. Kapangidwe kameneka kamapangitsa kuti mphamvu ziziyenda bwino komanso zimathandizira kuti pakhale kuwongolera bwino kwa kusungunuka kwamadzi, komwe kumakhala kofunikira popanga zinthu zapamwamba kwambiri.

Ubwino wogwiritsa ntchito migolo ya barrier-screw ndi:

- Kukhathamiritsa kosungunuka ndi kusakaniza bwino.

- Kuwongolera kutentha kwabwino, komwe kumalepheretsa kuwonongeka kwa zinthu zodziwika bwino.

- Kuchepetsa kuyenda kokoka, kumabweretsa kusungunuka kwabwinoko.

Ndazindikira kuti migolo iyi imakhudza kwambiri mtundu wa zinthu zomalizidwa zowumbidwa. Amathandizira kusunga kukhuthala kosasunthika, komwe ndikofunikira kuti mukwaniritse makulidwe a khoma limodzi ndi kukhulupirika kwazinthu zonse.

Migolo Yosakaniza-Screw

Migolo yosakaniza-screw imapangidwa kutikuwonjezera mtundu ndi zowonjezera kubalalikamu kuumba mphamvu. Nthawi zambiri ndimagwiritsa ntchito zotchinga ndi mapangidwe a Maddock, chifukwa amatsimikizira kusungunuka kwabwinoko ndikuletsa ma bits osasungunuka kuti asatseke dongosolo. Kuthekera kumeneku kumapangitsa kuti pakhale zolakwika zochepa komanso kusinthasintha kwamtundu pazogulitsa zomaliza.

Ubwino wa kusakaniza-screw migolo ndi monga:

- Kupititsa patsogolo kusungunuka kwachangu, kuchepetsa kuwonongeka kwa kutentha.

- Kukhathamiritsa kusakanikirana kwabwino, zomwe zimapangitsa kuti pakhale kusakanikirana bwino kwa ma polima ophatikizika.

- Kuwongolera bwino pa kukakamiza ndi kuyenda, kuonetsetsa kulondola kwazithunzi.

Ndikuwona kuti migolo iyi imakhala yopindulitsa makamaka pogwira ntchito ndi zovuta zosakanikirana za polima, chifukwa zimapereka kusinthasintha kofunikira komanso kuchita bwino pakupanga kwapamwamba.

Kusankha Mgolo Wowomba Woyenera

Mfundo Zofunika Kuziganizira

Posankha mbiya yowombera, ndimaganizira zinthu zingapo zofunika kuti zitsimikizire kuti zikuyenda bwino. Mtundu uliwonse wa polima uli ndi zofunikira zapadera zomwe zimakhudza kusankha kwanga. Nazi zina zofunika kuziganizira:

- Kugwirizana kwazinthu: Ma polima osiyanasiyana amafunikira mapangidwe apadera. Mwachitsanzo, pogwira ntchito ndi PMMA, ndimasankha wononga pang'onopang'ono ndi chiŵerengero cha kutalika ndi m'mimba mwake cha 20-22 ndi chiŵerengero cha kuponderezana kwa 2.3 mpaka 2.6. Kwa PET, ndimakonda kameta kakang'ono kakang'ono kamene kamakhala ndi chiwerengero cha 1.8-2, kupewa malo osakanikirana kumapeto. PVC imafuna kumeta ubweya wocheperako wokhala ndi zida zosagwira dzimbiri komanso chiŵerengero chautali ndi m'mimba mwake cha 16-20.

- Kujambula Geometry: Geometry ya screw barrel imakhudza kwambiri kukonza. Nthawi zambiri ndimatchula zakutsatira tebulo kuti munditsogolere zisankho zanga:

| Mtundu wa Screw | Chiwerengero cha L/D | Kufotokozera kwa Ntchito |

|---|---|---|

| General Cholinga | 20:1 | Oyenera mapulasitiki wamba koma amatha kuwonetsa kusiyanasiyana kwamitundu. |

| Zotchinga Zotchinga | 24:1 | Kupititsa patsogolo kusakaniza kwa mapulasitiki olimbikitsidwa. |

| Zopatukana Zopangira | 18:1 | Imathandiza kuti zinthu zomwe sizimva kutentha zisawonongeke. |

| Kusakaniza Screws | 22:1 | Amapereka yunifolomu kusungunuka kwa mapulasitiki apadera. |

- Mikhalidwe Yachilengedwe: Ndimamvetseranso kutentha ndi chinyezi cha chipinda cha makina. Kusunga malo okhazikika kumathandiza kupewa kuwonongeka kwa zida. Ndikuonetsetsa kutikutentha kumakhala pakati pa 25 ℃ - 30 ℃ ndi chinyezi pa 40% - 60%.

Impact pa Production Efficiency

Mtsuko wowomba bwino ukhoza kupititsa patsogolo kupanga bwino. Ndawona kuti screw yopangidwa bwino imakulitsa nthawi yozungulira polumikizana ndi zolinga za purosesa. Nazi zinthu zina zomwe zimakhudza kugwira ntchito bwino:

- Kujambula Geometry: Ichi ndikwambiri parameter yomwe imakhudza kutulutsandi chitukuko cha kuthamanga. Kukonzekera koyenera kungapangitse mitengo yofulumira kupanga.

- Kutentha Mbiri: Ndikuwona kuti mbiri yabwino yotenthetsera potengera kapangidwe ka screw imakulitsa mphamvu zamagetsi, zomwe zimakhudza nthawi yozungulira. Mapangidwe owongolera a screw amathandizira kukhazikika pamene akulimbana ndi zolinga za nthawi yozungulira.

- Compression Zone: Malo oponderezedwa amatenga gawo lofunikira kwambiri pakudutsa, makamaka pama frequency apamwamba ozungulira. Ndikuwonetsetsa kuti mapangidwewo akugwirizana ndi kupanga kwanga kumafunika kukulitsa zotulutsa.

Chikoka pa Ubwino Wazinthu

Kusankha kwa kuwomba mbiya yowononga kumakhudza mwachindunji mtundu wa chinthu chomaliza. Ndimayang'ana mbali zingapo kuti nditsimikizire zotsatira zabwino kwambiri:

- Sungunulani Quality: Mtsuko wopangidwa bwino umasunga kukhuthala kosasinthasintha, komwe ndikofunikira kuti mukwaniritse makulidwe a khoma lofanana. Kusasinthika kumeneku kumabweretsa kukhulupirika kwazinthu.

- Kugwiritsa Ntchito Mphamvu: Kugwiritsa ntchito bwino kwa screw ndi mbiya ndikofunikira pakugwiritsa ntchito mphamvu. Ndaphunzira kuti kuvala ndi kung'ambika kungayambitse kusagwira ntchito bwino, kuonjezera kugwiritsira ntchito mphamvu pamene kusiyana pakati pa screw ndi mbiya kukukulirakulira. Izi zimakhudza mtundu wosungunuka ndipo zimafunikira mphamvu zambiri kuti zisungidwe.

- Njira Zoyesera: Ndimayang'anira nthawi zonse ndikuwunika magawo ofunikira monga kuthamanga, kutentha, ndi liwiro la screw. Njira yolimbikitsirayi imandithandiza kuzindikira zinthu msanga ndikukhala ndi khalidwe labwino.

Poganizira mozama zinthu izi, nditha kusankha mbiya yoyenera yowomba yomwe imagwirizana ndi zolinga zanga zopanga ndikuwonetsetsa kutulutsa kwapamwamba.

Kusankha mtundu wa screw barrel yoyenera ndikofunikira kuti muwongolere njira zowomba. Ndikukulimbikitsani kuti muwunike zomwe mukufuna kupanga musanapange chisankho.

Mtengo wolipiridwa pachigawochi ndi chiyambi chabe. Moyo wogwira ntchito wa mbiya ukhoza kukhala waufupi kwambiri, malingana ndi momwe unapangidwira ndi kugwiritsidwa ntchito.

Kusankhidwa kodziwitsidwa kumabweretsa kuchepetsa kukonza ndi kutsika, kuwonetsetsa kuti phindu la nthawi yayitali la ntchito zanu.

FAQ

Kodi ndi zinthu ziti zomwe zimakhudza kusankha kwa mbiya yowombera?

Ndimaganizira zogwirizana ndi zinthu, screw geometry, ndi chilengedwe posankha mbiya yowomba.

Kodi screw barrel imakhudza bwanji kupanga bwino?

Mtsuko wopangidwa bwino umakulitsa nthawi yozungulira, kupititsa patsogolo ntchito, komanso kuwongolera mphamvu zamagetsi, zomwe zimapangitsa kuti ziwonjezeke zopanga.

Kodi mtundu wa screw barrel ungakhudze mtundu wazinthu?

Inde, mbiya yoyenera yowononga imasunga kukhuthala kosasinthika, kuwonetsetsa makulidwe a khoma limodzi ndi kukhulupirika kwazinthu zonse.

Nthawi yotumiza: Sep-17-2025