Single screw barrel system samaphatikizira kusinthasintha kozungulira kapena kozungulira komwe kumapezeka pamapangidwe apawiri. Mu 2025, migolo imodzi yokhayo imatsogolera msika wa extrusion. Tebulo ili pansipa likuwonetsa kupitilira kwawo kulamulira:

| Chaka | Gawo Lamsika Limodzi la Screw Barrel (%) | Zolemba |

|---|---|---|

| 2023 | 60 | Msika waukulu kwambiri pakati pa mitundu ya extruder |

| 2025 | ~ 60 kapena kupitilira apo | Chiyerekezo chotengera kakulidwe kokhazikika |

Opanga amasankha pakati pa zosankha ngatiPVC chitoliro chimodzi mbiya screw, single screw mbiya powomba akamaumba,ndimbiya ya pulasitiki imodzipoganizira kapangidwe ka screw, zinthu za mbiya, ndi zofuna za gawo.

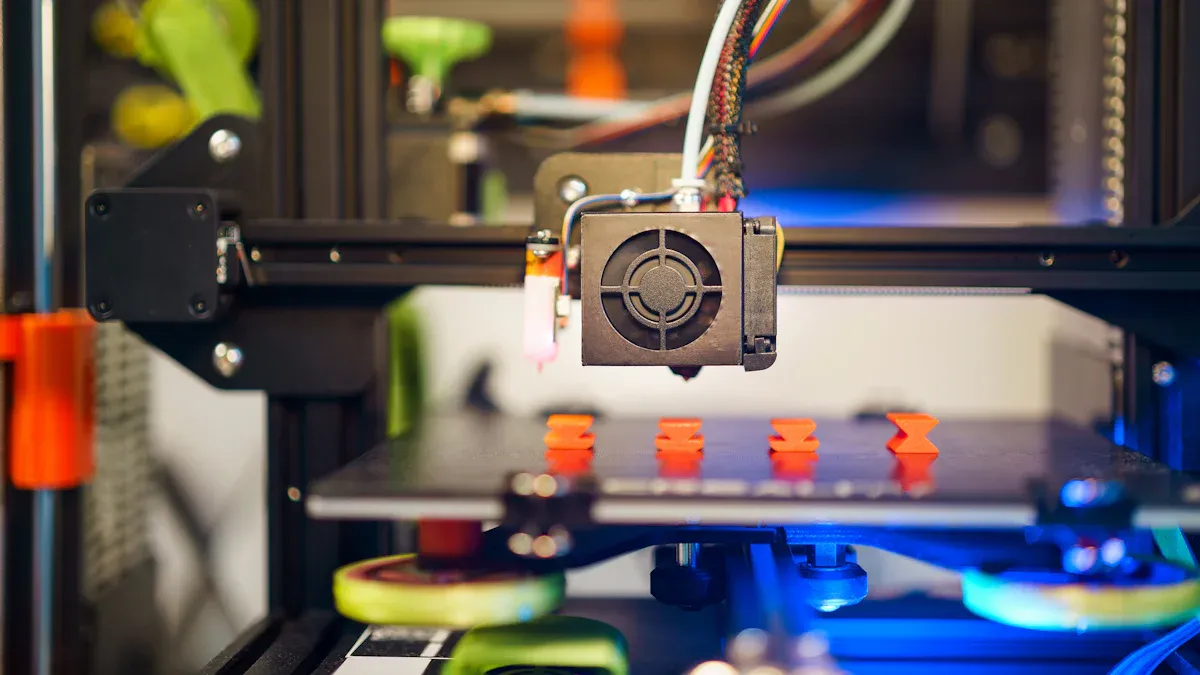

Single Screw Barrel: Magulu Ofunika Kwambiri

PVC Pipe Single Screw Barrel

PVC pipe single screw migolo imagwira ntchito yofunika kwambiri pakutulutsa mapaipi omanga, mapaipi, ndi magetsi. Opanga amapanga migolo iyi ndi akapangidwe kosavuta, zomwe zimachepetsa kulephera kwa makina ndikupanga kukonza molunjika. Ntchito mkulu-mphamvu aloyi zitsulo ndichithandizo cha nitridingkumawonjezera kuuma ndi kuvala kukana. Kapangidwe kameneka kamapangitsa kusungunuka kosasinthasintha, kusakanikirana, ndi kutumiza kwazinthu za PVC. Tebulo ili m'munsiyi ikuwonetsa zofunikira:

| Mbali | PVC Pipe Single Screw Barrels |

|---|---|

| Kupanga | Mapangidwe osavuta, odalirika |

| Kusamalira | ukadaulo wosavuta, wocheperako wofunikira |

| Ndalama Zogwirira Ntchito | M'munsi, ntchito yabwino |

| Kuwongolera Kutentha | Zosavuta kusamalira |

| Kukhalitsa | Chitsulo champhamvu champhamvu kwambiri, chopangidwa ndi nitride kuti chisavale |

| Kugwiritsa Ntchito Kuyenerera | Oyenera muyezo PVC chitoliro extrusion |

Migolo iyi imayang'anira kupanga mapaipi a PVC ang'onoang'ono mpaka apakatikati chifukwa chodalirika komanso kutsika mtengo.

Single Screw Barrel Yowomba Akamaumba

Migolo yaing'ono yokhala ndi zomangira imathandizira kupanga mabotolo, zotengera, ndi zinthu zina zopanda kanthu. Akatswiri amakonzekeretsa migolo imeneyizomangira chakudya groovedndi maulendo akuya kuti apititse patsogolo kusungunuka kwa utomoni ndi kusakaniza. Gawo losanganikirana lotchinga pafupi ndi screw end limathandizira kusakanikirana kwa polima ndikuwonetsetsa kusungunuka kofanana. Kuphatikizika kwakukulu kumathandizira kusungunula homogeneity, zomwe ndizofunikira pakukhazikika kwa kuwira komanso mtundu wafilimu. Mapangidwe apamwamba angaphatikizepo masensa owunikira kusungunuka kwa kutentha ndi kutentha, kuwonetsetsa kuwongolera kolondola. Kugwiritsira ntchito zitsulo zopangira kutentha kumapereka kulimba komanso kukana kuvala.

- Zomangira zomangirira zimathandizira kusungunuka kwa utomoni ndi kutumiza.

- Njira zozizira zophatikizika zimawongolera kutentha panthawi ya extrusion.

- Masensa omwe angasankhidwe amathandizira kuyang'anira nthawi yeniyeni.

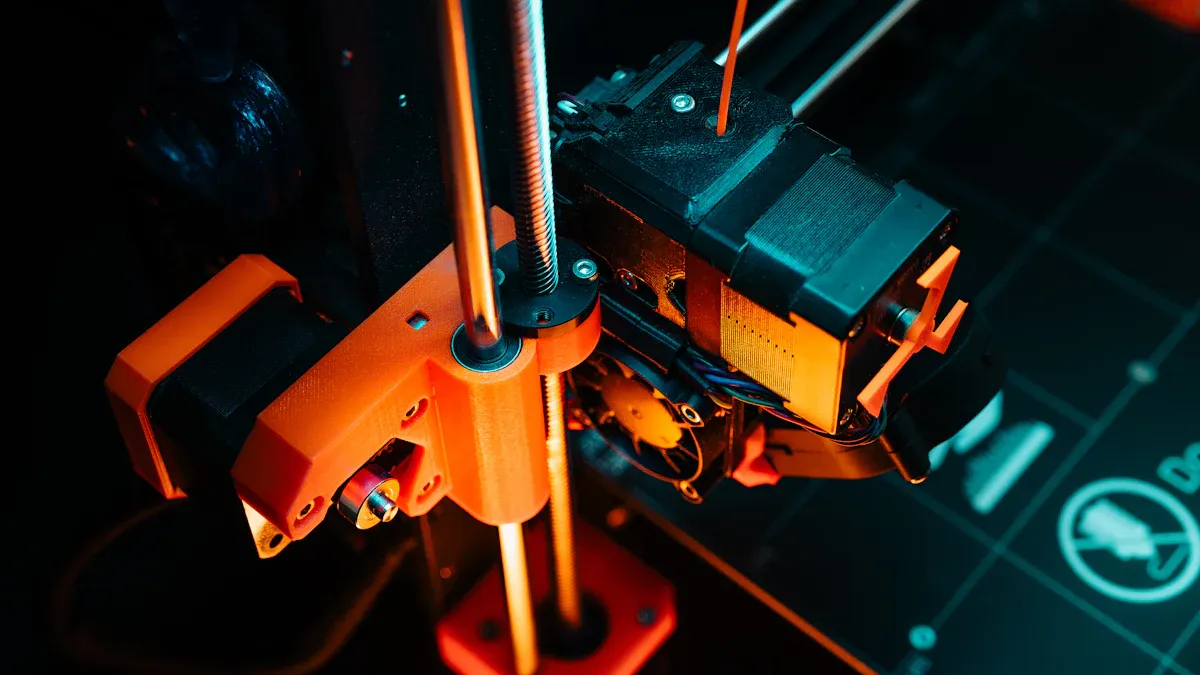

PE Pipe Extruder Single Screw Barrel

PE chitoliro extruder single wononga migolo ndi opangidwa ndi katundu wapadera wa polyethylene. Migolo iyi imatsimikizira kusungunuka bwino, kusakaniza, ndi kutumiza zinthu za PE. Mapangidwewa amathandizira kutulutsa kwakukulu komanso kusungunuka kosasinthasintha, kukwaniritsa zofuna za mafakitale a PE. Opanga amagwiritsa ntchito kusiyanasiyana kwa zinthu ndi kapangidwe kake, monga ma aloyi achitsulo ndi chitsulo cha nitrided, kuti agwirizane ndi ma polima ndi zofunikira zopangira. Gawo la ntchito limaphatikizapo mafakitale monga zamagalimoto, zida zapakhomo, ndi mapulasitiki wamba, kuwonetsa kusinthasintha kwa migolo iyi.

- Zosankha zazing'ono, zapakatikati, ndi zazikulu zazitalizigwirizane ndi masikelo osiyanasiyana opanga.

- Wokometsedwa kwa mkulu-voliyu mafakitale processing ndi zogwirizana linanena bungwe.

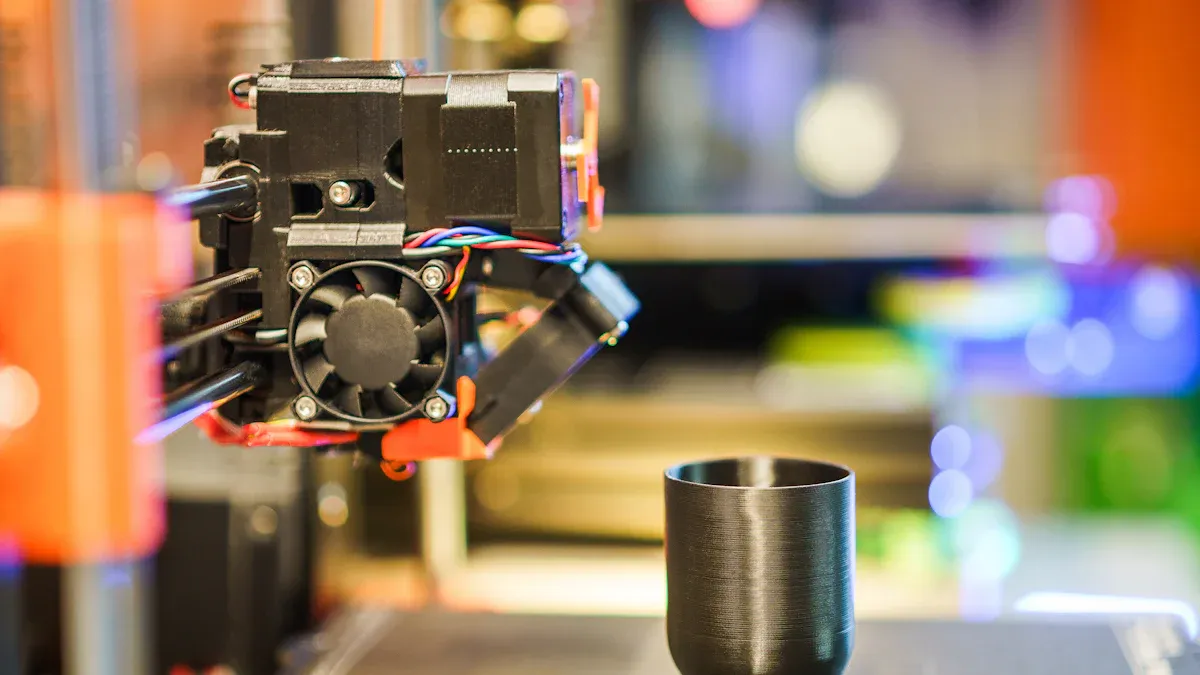

Kuchita ndi Kuchita Bwino mu Single Screw Barrel Systems

Kusakaniza ndi Homogenization Maluso

Kusakaniza ndi homogenization kumagwira ntchito yofunika kwambiri mu ndondomeko ya extrusion. Single screw barrel system imasuntha zinthu zopangira kudzera m'malo odyetsera, kusungunuka, ndi ma metering. Chophimba chozungulira, chophatikizidwa ndi kutentha kwa mbiya, chimasungunula zinthu ndikuchikankhira patsogolo. Njirayi imakanikiza ndikusakaniza polima wosungunuka, kuwonetsetsa kugawidwa kofananako isanatuluke mukufa.

Mainjiniya nthawi zambiri amawonjezera zida zosakaniza kuti apititse patsogolo ntchito. Zosakaniza zobalalika, monga mitundu ya Egan ndi Maddock, zimaphwanya zipolopolo ndikuwonjezera kusungunuka pogwiritsira ntchito shear. Zosakaniza zogawa, monga Saxton kapena zosakaniza za pini, zimagawaniza ndikugawanso kusungunuka, zomwe zimathandiza kukwaniritsa ngakhale mtundu ndi kugawa kowonjezera. Zomangira zotchinga zimalekanitsa magawo olimba ndi osungunuka, zomwe zimapangitsa kusungunuka kwathunthu musanasakanizidwe. Zosankha zapangidwezi zimadalira zinthu komanso mtundu womwe mukufuna.

Langizo:Kusankhidwa koyenera kwa chosakanizira ndi screw geometry kumatha kusintha kwambiri homogenization, makamaka pazinthu zokhala ndi utoto kapena zowonjezera.

Komabe, anjira yopita kunjira imodzimu migolo imodzi wononga akhoza kuchepetsa kusakaniza. Kuthamanga kwa polima kumasiyanasiyana kudera lonselo, zomwe zingayambitse kusintha kosakwanira. Kuti athane ndi izi, mainjiniya amagwiritsa ntchito maulendo owonjezera a ndege ndi magawo osakanikirana, ngakhale izi zitha kukulitsa kukana kwakuyenda ndi kutentha kusungunuka. Mapangidwe okhathamiritsa a screw amathandizira kuthana ndi zovuta izi, kutulutsa zotulutsa zapamwamba komanso zosasinthika.

Kutulutsa ndi Kutulutsa

Kutulutsa kumayesa kuchuluka kwa zinthu zomwe extruder imayendera pakapita nthawi. Mu 2025, mbiya imodzi yokhala ndi mainchesi 100 mm imafikira 150 kg / h. Zojambula zokongoletsedwa bwino zitha kukulitsa izi ndi 18% mpaka 36%. Tebulo ili likufotokozera mwachidule magawo ofunikira:

| Parameter | Tsatanetsatane / Makhalidwe |

|---|---|

| Screw Diameter | 100 mm |

| Zomwe Zachitika | 150kg/h |

| Kuzama kwa Metering Channel | 4 mpaka 8 mm |

| Mlingo Kuwonjezeka ndi Screw Optimization | 18% mpaka 36% |

| Kutentha Kwambiri Kwambiri | ~ 230 ° C |

| Zolepheretsa | Kuzizira, extrudate kutentha |

Kuzama kwa tchanelo mu wononga kumachepetsa kumeta ubweya ndi kutentha kwamadzi, zomwe zimalola kutulutsa kwakukulu. Komabe, kuzirala kwa mtsinje ndi malire a kutentha nthawi zambiri kumalepheretsa kutulutsa kwakukulu. Screw geometry, monga pitch ndi groove wide, imakhudzanso kuchuluka kwa ma extrusion ndi mtundu wa pulasitiki.

Kugwiritsa Ntchito Mphamvu ndi Kukhazikika Kwadongosolo

Single screw extruder imadziwika chifukwa cha mphamvu zawo zogwirira ntchito molunjika. Mapangidwe awo osavuta komanso owongolera mphamvu zamagetsi zamagetsi zimapangitsa kuti pakhale mphamvu zochepa poyerekeza ndi machitidwe ovuta kwambiri. Kwa zipangizo zofanana, zimadya mphamvu zochepa ndipo zimagwira ntchito ndi mtengo wotsika.

Pali zinthu zingapo zomwe zimakhudza kugwiritsa ntchito mphamvu:

- Kugwira ntchito bwino kwa injini ndi kapangidwe ka screw kumakhudza kugwiritsa ntchito mphamvu.

- Kutenthetsa ndi kuziziritsa kumathandizira kuti kutentha kuzikhala koyenera.

- Zoyendera, monga kuthamanga kwa screw ndi kutentha kwa migolo, zimakhudza magwiridwe antchito.

Kukhazikika kwadongosoloimaonetsetsa kuti zinthu zili bwino pakugwira ntchito mosalekeza. Chiyerekezo chautali ndi m'mimba mwake, chiŵerengero cha kuponderezana, ndi mbiri yowononga zonse zimakhudza kusungunuka ndi kusakaniza.Kusankha zinthuchifukwa wononga ndi mbiya zimakhudza kulimba komanso kuyanjana ndi mapulasitiki osiyanasiyana. Oyendetsa amawunika kutentha ndi kuthamanga pogwiritsa ntchito masensa kuti azindikire ndikuwongolera kusinthasintha. Makina owongolera otsogola, monga owongolera malingaliro osamveka bwino, amathandizira kuti zinthu zizikhazikika komanso kuwongolera kusungunuka kwabwino.

Zindikirani:Kukhazikika kwadongosolo kumalepheretsa kusiyanasiyana kwa zinthu zomwe zimapangidwa ndikuchepetsa zinyalala, kupangitsa kuyang'anira ndi kuwongolera ndikofunikira pakupanga kodalirika.

Kukwanira kwa Kagwiritsidwe Ntchito Kwa Mapangidwe Amodzi a Screw Barrel

Kugwirizana Kwazinthu ndi Zosowa Zopangira

Kugwirizana kwa zinthu kumayima ngati chinthu chofunikira kwambiri posankha mbiya imodzi yowotchera. Opanga amasankha mbiya zipangizo ndi mankhwala potengera mtundu wa pulasitiki ndi malo enieni processing. Zinthu zotsatirazi zimagwiritsidwa ntchito kwambiri:

- 38CrMoAIA ndi SKD61 amapereka kuvala mwamphamvu komanso kukana dzimbiri kwa mapulasitiki wamba.

- Ma aloyi a Bimetallicperekani kulimba kokhazikika, makamaka kwa mapulasitiki otayira kapena opangidwanso.

- Mapangidwe a screw ndi mbiya amafanana ndi zofunikira zamakina ndi zida zosiyanasiyana.

Zidazi zimakwaniritsa zofunikira zingapo pokonza, monga kukana kuvala, kukana dzimbiri, komanso kusunga bwino kwambiri kupanga. Migolo yosavala kwambiri imakhala yofunikira pokonza mapulasitiki odzazidwa kapena opangidwanso. Zosankha zosagwirizana ndi dzimbiri zimateteza kuzinthu zowonjezera kapena ma polima. Gome ili m'munsili likufotokozera mwachidule momwe zida zosiyanasiyana za migolo zimakwaniritsa zofuna zosiyanasiyana:

| Mtundu Wazinthu | Chithandizo/Kupaka | Zofunikira Zokonzekera Zathetsedwa | Pulasitiki Yogwirizana |

|---|---|---|---|

| SCM-4 High-Hardness Alloy Steel | High-Frequency Quenching / Hard Chrome | Valani kukana, kukana dzimbiri, kupirira kukameta ubweya ndi kutentha | PE, PP, PVC, ABS, etc. |

| SACM-1 Aloyi Zitsulo | Chithandizo cha Nitriding | Kuvala bwino komanso kukana dzimbiri | PE, PP, PVC, ABS, etc. |

| SCM-4 Bimetallic Aloyi | Pamwamba wosanjikiza (0.8-1.2mm) | Kuvala kowonjezera komanso kukana dzimbiri | Mapulasitiki osiyanasiyana kuphatikiza mapulasitiki opangidwanso ndi odzazidwa |

Akatswiri amaganiziranso kukula kwa kutentha kwa zinthu zolimbana ndi dzimbiri. Amafananiza wononga ndi mbiya mosamala kuti asamangidwe kapena kuwonongeka panthawi yogwira ntchito. Zovala zapamwamba, monga Colmonoy kapena tungsten alloys, zimateteza ku ma abrasive ndi kuwonjezera moyo wautumiki. Zosankha izi zimatsimikizira kuti mbiya imodzi yokhayo imakhalabe ndi magwiridwe antchito abwino pamapulasitiki osiyanasiyana ndikusintha.

Ubwino Wazinthu ndi Kusasinthika

Mapangidwe a single screw mbiya mwachindunji zimakhudza khalidwe ndi kusasinthasintha kwa extruded mankhwala. Mgolo wopangidwa bwino umatsimikizira kusungunuka koyenera, kusakaniza bwino, ndi kutumiza kokhazikika kwa polima. Njirayi imachepetsa zolakwika ndikusunga zofanana muzogulitsa zomaliza. Zinthu zazikuluzikulu zamapangidwe ndi:

- Chiyerekezo cha kutalika kwa m'mimba mwake (L/D) chimayang'anira nthawi yokhalamo komanso kasamalidwe ka kutentha.

- Compression ratio ndi screw geometry zimatsimikizira kusakanikirana ndikusungunula homogeneity.

- Zitsulo za migolo, monga malo a bimetallic kapena nitrided, zimawonjezera kukana komanso kukhazikika kwa kupanga.

Kusungunula koyenera ndi kusakaniza kumateteza kusagwirizana, monga kusinthasintha kwa mitundu kapena zolakwika za dimensional. Screw geometry imathandizira kuwongolera kutentha, kupewa kuwonongeka kapena kusungunuka kwambiri. Kuthamanga koyenera ndi kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe ka kayendetsedwe kake. Mapulofailo a makonda, monga zomangira zotchingira kapena zosakaniza, amawongolera kusungunuka ndi kufalikira kwamitundu. Kusamalira nthawi zonse ndi kukonza wononga ndi mbiya kumathandiza kuti zinthu zikhale zabwino kwambiri pakapita nthawi.

Langizo: Kufananiza zomangira zomangira ndi mtundu wa pulasitiki kumapangitsa kuti zinthu zikhale bwino komanso zimachepetsa chiwopsezo cha zolakwika.

Zofunikira Zapadera Zamakampani

Mafakitale osiyanasiyana amafunikira mawonekedwe apadera kuchokera ku zida zawo za extrusion. The single screw mbiya iyenera kukwaniritsa zofunikira izi kuti zitsimikizire kupanga kodalirika komanso kothandiza. Tebulo ili m'munsiyi likuwonetsa zofunikira pazantchito zazikulu:

| Makampani / Ntchito | Zofunika Zazikulu ndi Zoganizira |

|---|---|

| Pulasitiki Extrusion | Fananizani mbiya yofananira ndi mtundu wazinthu (namwali, zobwezerezedwanso, zodzazidwa, ma polima osakanikirana); Chiŵerengero cha L/D nthawi zambiri 24:1 mpaka 36:1; Chiŵerengero cha kuponderezana ndi madera osakanikirana opangidwa kuti apangidwe; mankhwala pamwamba monga nitriding kapena bimetallic zokutira kuti asavale; Zovala zapamwamba zimafuna migolo ya bimetallic kuti ikhale yolimba |

| Chakudya Extrusion | Pang'ono wononga mbiya kusiyana kusunga ukhondo ndi kupewa kuipitsidwa; Mipata yotsika yometa ubweya wa zinthu zomwe sizimva kutentha |

| Rubber ndi Chemical Extrusion | Zopaka zolimbitsa, zosavala kuti zigwirizane ndi mphira wodzaza ndi abrasive; Nthawi zina mipata yotakata kuti muchepetse mphamvu zakumeta ubweya |

Kutulutsa kwapulasitiki nthawi zambiri kumafuna kulolerana kolimba kwa mbiya ndi zokutira zapadera kuti zigwirizane ndi ma polima osiyanasiyana, kuphatikiza omwe ali ndi zodzaza kapena zobwezerezedwanso. Kutulutsa zakudya kumapangitsa kuti pakhale zaukhondo, zomwe zimafuna mipata yochepa komanso mapangidwe ang'onoang'ono ometa ubweya kuti ateteze zinthu zodziwika bwino. Rubber ndi mankhwala extrusion amapindula ndi zokutira zolimbitsa ndipo, nthawi zina, mipata yokulirapo yosamalira zida zowononga ndikuchepetsa kuvala.

Kuyika bwino, kukonza, ndi kuwongolera kutentha kumakhudzanso kusankha migolo m'mafakitale onse. Kusungunula koyenera, kusakaniza, ndi kutumizirana zinthu kumakhalabe kofunikira kuti zinthu zikhale bwino komanso mizere yokhazikika yopangira.

Kuganizira za Mtengo ndi Kukonza kwa Single Screw Barrel

Ndalama Zoyamba ndi Zida Zakale

Ndalama zoyambira zopangira makina a screw barrel mu 2025 zimakhalabe zofikirika kwa opanga ambiri. Mitengo imachokera pa$10,000 mpaka $50,000, yomwe ndi yotsika kwambiri kuposa mtengo wa ma screw systems. Gome ili m'munsili likuwonetsa zinthu zazikulu zomwe zimakhudza mitengoyi:

| Factor | Kukhudza Mtengo |

|---|---|

| Ubwino Wazinthu | kalasi yapamwamba = mtengo wapamwamba |

| Mulingo wa Automation | Zowonjezera zokha = mtengo wapamwamba |

| Kusintha mwamakonda | Mapangidwe apadera = mtengo wapamwamba |

| Mbiri ya Wopereka | Zodziwika bwino = mtengo wapamwamba |

Migolo yodyera yokhala ndi screw imodzi imagwiritsa ntchito ukadaulo wosavuta komanso kapangidwe kake, zomwe zimapangitsa kuti ndalama zoyambira komanso zosamalira zikhale zochepa. Kuphweka kumeneku kumathandizanso kuchepetsa chiopsezo cha kulephera kwa makina. Kutalika kwa zida kumadalira kusankha kwazinthu, kapangidwe ka screw, ndi kukonza pafupipafupi. Zopaka zapamwamba ndi migolo ya bimetallic imatha kuwonjezera moyo wautumiki, makamaka pokonza zida zowononga.

Ndalama Zogwirira Ntchito ndi Kugwiritsa Ntchito Mphamvu

Ndalama zogwirira ntchito pamakina a screw barrel sizingadziwike bwino chifukwa chakugwiritsa ntchito mphamvu mokhazikika. Kugwiritsa ntchito mphamvu zambiri kumabwera chifukwa chotenthetsa mbiya ndikuyendetsa screw motor, yomwe nthawi zambiri imafunika pakati pa 3 ndi 50 kW. The screw motor palokha imagwiritsa ntchito 7 mpaka 15 kW. Chifukwa kufunikira kwa mphamvu kumakhalabe kosasunthika, opanga ndalama amatha kupanga bajeti mosavuta ndikusunga ndalama zopangira. Themakina ntchito wononga komanso amapanga kutentha mkati, zomwe zimachepetsa kufunika kwa kutentha kowonjezera komanso kumapangitsa kuti mphamvu zitheke. Kugwiritsa ntchito matekinoloje opulumutsa mphamvu monga ma frequency frequency drives ndi njira zowunikira zimatha kutsitsa mtengo.

Langizo: Kugwiritsa ntchito mphamvu kosasunthika mu extrusion kumapangitsa kuti pakhale zotsalira zochepa komanso bwino zakuthupi poyerekeza ndi njira zina zomangira.

Kusamalira ndi Kuvala Zinthu

Kukonza mbiya zomangira zing'onozing'ono kumayang'ana kwambiri kuyang'anira kuvala ndikusunga dongosolo kuti liziyenda bwino. Mavuto omwe amapezeka nthawi zambiri amaphatikizapo kusungunuka kwabwino, kuvala kofulumira kuchokera kuzinthu zowonongeka, komanso kulephera kwa ntchito. Valani zinthu monga ma abrasive fillers, zowonjezera zowononga, komanso kutentha kwambiri kumatha kufulumizitsa kufunika kokonzanso. Malo ovala kwambiri, monga malo odyetserako ndi kutulutsa, amafunikira kuwunika pafupipafupi. Kugwiritsa ntchito zida zapamwamba ndi zokutira kumathandiza kukulitsa moyo wautumiki ndikuchepetsa pafupipafupi kukonza. Mapulogalamu oletsa kukonzanso, kuyeretsa nthawi zonse, ndi kuyang'anira kavalidwe kamene kamalola opanga kukonzekera kukonza ndikupewa kutsika kosayembekezereka.

Zam'tsogolo ndi Zatsopano mu Single Screw Barrel Technology

Zotsogola Zatekinoloje mu 2025

Opanga akupitiliza kuyambitsa matekinoloje atsopano omwe amawongolera magwiridwe antchito ndi machitidwe a extrusion. Zatsopano zingapo zikuwonekera mu 2025:

- Kuyenda bwino kwazinthu kumachepetsa kutsekeka komanso kutsika, zomwe zimawonjezera nthawi yopanga.

- Kutengerako kutentha kumasunga kutentha koyenera, kumapangitsa kuti zinthu zikhale bwino komanso kusasinthasintha kwazinthu.

- Kuwonjezeka kwa kulimba kuchokera ku zipangizo zapamwamba kumabweretsa kukonzanso kochepa ndi kusinthidwa, kusunga nthawi ndi ndalama.

- Zosintha zomwe zingasinthidwe zimalola kuti zigwirizane ndi zosowa zinazake zopangira, kukulitsa luso.

Mapangidwe a Helibar mum'badwo wotsatira amapereka kutulutsa kwapamwamba komanso kusungunuka kwamphamvu kwamphamvu. Kapangidwe kameneka kamachepetsanso kutentha kosungunuka komanso kumapangitsa kusungunula homogeneity. Kuchepetsa kuvala kwa migolo komanso nthawi yayitali yokhalamo kumathandizira kuti zinthu zisamayende bwino. Mafakitole ambiri tsopano amagwiritsa ntchito kukonza zolosera komanso njira zowongolera zapamwamba ngati gawo lopanga mwanzeru. Machitidwewa amayang'anira thanzi la zida ndi ndondomeko ya ndondomeko mu nthawi yeniyeni, zomwe zimathandiza kupewa nthawi yosayembekezereka ndikuonetsetsa kuti ntchito ikuyenda bwino.

Zofuna Zamsika ndi Kukhazikika

Zomwe zikuchitika pamsika mu 2025 zikuwonetsa kusintha kwachangu mumakampani apulasitiki ndikukulitsa kuzindikira kwachilengedwe. Zinthu zingapo zimayendetsa kufunikira kwa zida zapamwamba za extrusion:

- Makampani apulasitiki amakula mwachangu, makamaka ku Asia-Pacific, chifukwa chakukula kwamatauni komanso zosowa za ogula.

- Zida zopepuka zimawona kugwiritsidwa ntchito kochulukira m'magawo amagalimoto ndi ndege.

- Zaukadaulo, monga zomangira zotchingira ndi masinthidwe a CAD/CAM, zimawongolera magwiridwe antchito ndikuchepetsa kugwiritsa ntchito mphamvu.

- Malamulo okhwima okhudza chilengedwe amakakamiza opanga makinawo kuti azitengera makina osagwiritsa ntchito mphamvu komanso ochepetsera zinyalala.

- Makampani olongedza katundu akukulirakulira, kuyang'ana kwambiri zinthu zosinthika, zowonongeka, komanso zobwezerezedwanso.

- Makampani 4.0 ndi kupanga mwanzeru kumathandizira kuwunika munthawi yeniyeni komanso magwiridwe antchito.

- Kuphatikizika ndi kupeza kumathandiza makampani kukulitsa luso laukadaulo.

Zovuta zokhazikika zimapanga chitukuko chaukadaulo wa extrusion.Opanga amatenga zinthu zobwezerezedwanso ndikuchepetsa zinyalala zamakina. Ambiri amagwiritsa ntchito ma alloys obwezerezedwanso ndi makina oyeretsera otengera madzi kuti athandizire zolinga zachuma zozungulira. Magwero a mphamvu zongowonjezwdwa ndi zida zogwiritsa ntchito mphamvu zimathandizira kuchepetsa kutulutsa mpweya. Zopaka zapamwamba komanso uinjiniya wolondola zimachepetsa zomata ndikugwiritsa ntchito mphamvu, zomwe zimachepetsa kukhazikika kwachilengedwe. Izi zimathandiza makampani kuti akwaniritse miyezo yokhwima ya chilengedwe ndikusintha mbiri yawo pamsika.

Malamulo achilengedwe m'magawo ngati France ndi European Union amafunikira kutulutsa kokhazikika komanso kukonzanso zinthu. Opanga akuyenera kupanga zatsopano kuti agwirizane ndi malamulowa pomwe akusunga zotsika mtengo. Kukakamiza kowongolera uku kumabweretsa mayankho okhazikika komanso ndalama zopitilira kafukufuku ndi chitukuko.

Mkangano wosinthasintha ndi wotsutsana sukhudza machitidwewa. Opanga amawakonda mu 2025 chifukwa chakuchita bwino, kudalirika, komanso kusinthika. Posankha, ayenera kugwirizanitsa mapangidwe a mbiya ndi zosowa zakuthupi, ganiziranikuvala kukana, ndikuyang'ana zinthu zomwe zimathandizira kuyang'anira digito ndi kupanga kosatha.

FAQ

Ubwino waukulu wa mbiya imodzi ya screw mu extrusion ndi chiyani?

Single screw migoloperekani magwiridwe antchito odalirika, kukonza kosavuta, komanso kugwiritsa ntchito bwino ndalama. Zimagwirizana ndi ntchito zambiri zamtundu wa extrusion mu 2025.

Kodi opanga aziyang'ana kangati mbiya zomangira imodzi?

Opanga amayenera kuyang'ana mbiya za screw imodzi pakatha miyezi itatu kapena isanu ndi umodzi. Kuyang'ana pafupipafupi kumathandiza kupewa kutha komanso kusasinthika kwazinthu.

Kodi ndondomeko ya mbiya imodzi yokha ingagwiritsirenso ntchito mapulasitiki?

Inde,ziboliboli imodziamatha kukonza mapulasitiki obwezerezedwanso. Kugwiritsa ntchito migolo ya bimetallic kapena zokutira zapadera kumawonjezera kukana ndikuwonjezera moyo wa zida.

Nthawi yotumiza: Jul-10-2025