Kumeta ubweya wa mphamvu kumagwira ntchito yofunika kwambiri pakugwira ntchito kwa pulasitiki yamapasa screw extruder. Zimatanthawuza mphamvu yomwe imapangitsa kuti zigawo za zinthu zisunthike, zomwe zimakhudza kwambiri zinthu zakuthupi. Mwachitsanzo, kumeta ubweya wambiri kumawonjezera kusakaniza ndi kugawa kutentha. Mu aTwin Plastic Screw Barrel, mapangidwe osungunuka amapangitsa kuti zinthu ziziyenda bwino ndikuchepetsa kutentha, chifukwa kuthamanga kwa 40 bar kumatha kukweza kutentha ndi 20 ° C. Komanso, aConical Twin Screw Extruder Screw Barrelimakulitsanso njirazi pogwirizanitsa mphamvu ya kumeta ubweya ndi kutulutsa, pameneTwin Screw Barrelmapangidwe amathandizira kuti pakhale mphamvu zonse munjira ya extrusion.

Zoyambira za Plastic Twin Screw Extruder

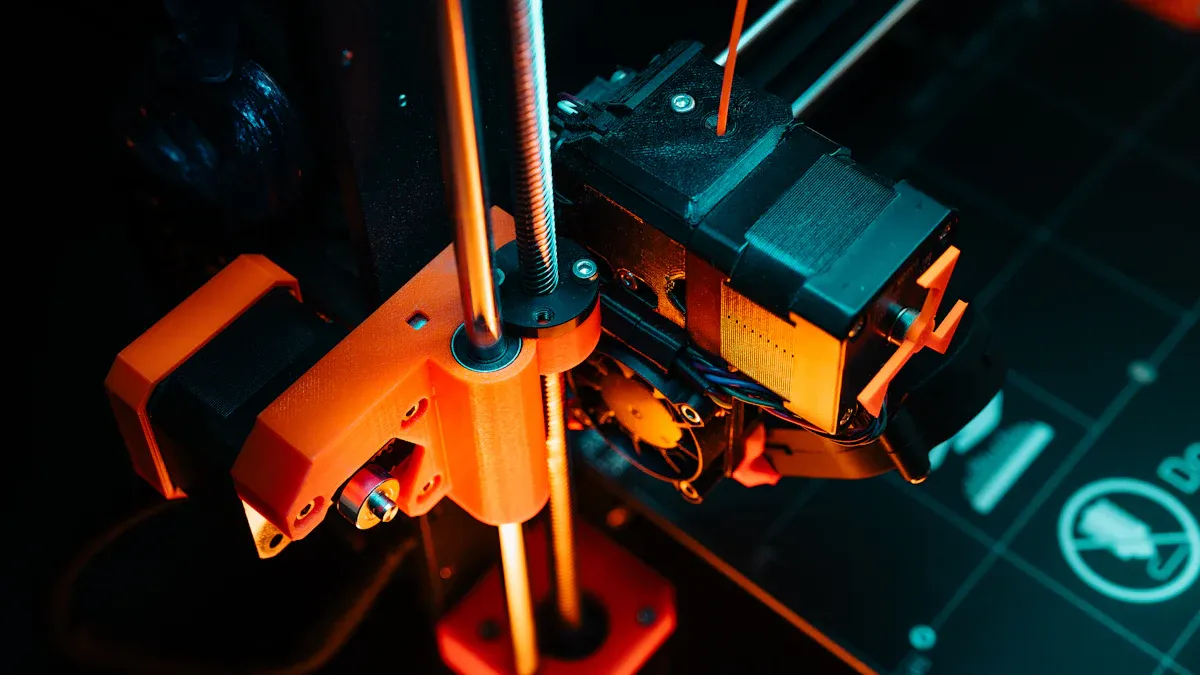

Zigawo Zofunikira za Extruder

A pulasitiki mapasa wononga extruderimakhala ndi zigawo zingapo zofunika zomwe zimagwirira ntchito limodzi kuti zigwiritse ntchito bwino. Izi zikuphatikizapo:

- Hopper: Malo olowera kumene zipangizo zimadyetsedwa mu dongosolo.

- Mgolo: Chipinda chachikulu chomwe zida zimasungunuka ndikusakanikirana.

- Screw Conveyor: Udindo wonyamula zinthu kudzera pa extruder.

- Heating System: Amapereka kutentha koyenera kusungunula mankhwala apulasitiki.

- Kuwongolera Kutentha: Imaonetsetsa kuti zinthu zikuyenda bwino.

- Mutu wa Extrusion: Imaumba zinthuzo kukhala mawonekedwe ofunidwa pamene zikutuluka mu extruder.

Chigawo chilichonse chimakhala ndi gawo lofunikira pakuwonetsetsa kuti extruder imagwira ntchito bwino komanso imapereka zotulutsa zapamwamba kwambiri. Mwachitsanzo, liwiro la wononga wononga limalola kuwongolera bwino njira yotulutsira, pomwe kufa kosinthika kumathandizira kupanga mawonekedwe ndi makulidwe osiyanasiyana.

Udindo wa Screws ndi Barrel mu Shear Force Generation

Zomangira ndi mbiya ndizofunikira pakupanga kukameta ubweya wa mphamvu mu pulasitiki yamapasa wononga extruder. Zomangira zimazungulira mkati mwa mbiya, kupangitsa kukangana ndi kukakamiza komwe kumasungunuka ndikusakaniza zinthuzo. Zinthu monga kuthamanga kwa screw, diameter ya kufa, ndi machitidwe azinthu zimakhudza kwambiri mphamvu yakumeta ubweya. Mwachitsanzo:

| Parameter | Chikoka pa Shear Force Generation |

|---|---|

| Liwiro la Screw | Kuthamanga kwakukulu kumawonjezera mphamvu yodutsa ndi kutayika, kupititsa patsogolo mphamvu yometa ubweya. |

| Die Diameter | Ma diameter akulu amachepetsa kuthamanga ndi mphamvu, zomwe zimakhudza mphamvu yakumeta ubweya. |

| Makhalidwe Akuthupi | Zida zometa ubweya wa ubweya zimawonetsa kutsika komanso mphamvu zochepa poyerekeza ndi madzi a Newtonian. |

Kuyanjana kumeneku kumapangitsa kuti zinthu ziziyenda bwino komanso kusakanikirana kofanana.

Mphamvu Zoyenda Zofunikira mu Extruder

Zinthu otaya mphamvu mu pulasitiki amapasa wononga extruder kudziwa khalidwe la kusakaniza ndi chomaliza mankhwala. Njira zapamwamba zowerengera, monga CFD, zathandizira kumvetsetsa kwamphamvu izi. Njira monga voliyumu yamadzimadzi (VOF) ndi njira zoyikira mulingo zimatsata momwe madzi amalumikizirana panthawi yosakanikirana, kuwonetsetsa kuti njirayo ikuyendetsedwa bwino. Twin screw extruder amagwiritsidwa ntchito kwambiri m'mafakitale ngati mankhwala chifukwa cha kuthekera kwawo kosakanikirana. Pansi pazikhalidwe zokhazikika (30 kg/hr, 200 rpm), kupanikizika muchipinda chimodzi chooneka ngati C kumafika pafupifupi 2.2 MPa, ndi kutsika kwamphamvu kwa 0.3 MPa m'dera la intermeshing ndi 0,5 MPa m'malo ozungulira. Ma metrics awa amawonetsa kuthekera kwa extruder pogwira zinthu zosiyanasiyana.

Shear Force Mechanism mu Twin Screw Extrusion

Generation of Shear Force mu Extrusion Process

Mphamvu ya kukameta ubweya mu njira yowongola wononga yopangidwa ndi mapasa imayamba chifukwa cholumikizana pakati pa zomangira zozungulira ndi mbiya yoyima. Zomangirazo zikamazungulira, zimapanga kukangana ndi kukanikiza, zomwe zimapangitsa kuti zinthuzo zisokonezeke ndikuyenda. Kupindika kumeneku kumapanga mphamvu zometa ubweya zomwe zimagwira ntchito yofunika kwambiri pakusungunula, kusakaniza, ndi kupanga homogenizing zinthuzo. Zomangira zomangira zomangira zimatsimikizira kuti zinthuzo zimameta mosasinthasintha nthawi yonseyi.

Kusanthula manambala pogwiritsa ntchito njira ya voliyumu yamadzimadzi (VOF) kwawulula njira za hydrodynamic zomwe zimakhudzidwa ndi njirayi. Ikuwonetsa momwe mphamvu zometa ubweya, ma viscosity ratios, ndi chipwirikiti zimakhudzira microstructure ya immiscible alloys pakusakanikirana. Zotsatirazi zikugogomezera kufunikira kwa mphamvu zometa ubweya pozindikira khalidwe la rheological ndi ntchito yonse ya extrusion.

Maphunziro oyesera amathandiziranso njirayi. Mwachitsanzo, kafukufuku wa ma nanocomposites a dongo la polypropylene adawonetsa kuti ma screw extruder amapasa kubalalika kwakukulu poyerekeza ndi ma screw extruder amodzi. Izi zimatheka chifukwa cha mphamvu zometa ubweya wambiri zomwe zimapangidwa muzinthu ziwiri zomangira, zomwe zimawonjezera kutulutsa kwazinthu ndikuwongolera makina ake komanso kutentha.

Zinthu Zokhudza Shear Force

Zinthu zingapo zimakhudza m'badwo ndi kukula kwa mphamvu yometa ubweya mu pulasitiki mapasa screw extruder. Izi zikuphatikiza liwiro la screw, screw geometry, ndi viscosity yakuthupi.

- Liwiro la Screw: Kuchulukitsa liwiro la screw kumakweza kumeta ubweya, zomwe zimatsogolera ku mphamvu zometa ubweya wambiri. Komabe, kuthamanga kwambiri kungayambitse kuwonongeka kwa zinthu kapena kutenthedwa.

- Kujambula Geometry: Mapangidwe a zomangira, kuphatikizira kukwera kwake, kuya kwake kwa ndege, ndi mbali ya intermeshing, zimakhudza mwachindunji ntchito yometa. Mwachitsanzo, zomangira zokhala ndi ndege zozama kwambiri zimatulutsa mphamvu yometa ubweya wocheperako, pomwe zomangira zolimba zimakulitsa kumeta kwambiri.

- Kukhuthala kwa Zinthu: Zida zowoneka bwino zimafuna mphamvu zazikulu zometa ubweya kuti zikwaniritse kusakaniza koyenera ndi kusungunuka. Mosiyana ndi zimenezi, zipangizo zotsika kwambiri zimatha kuyenda mosavuta, kuchepetsa mphamvu yometa.

Kafukufuku wowerengera adasanthula zinthu izi mwatsatanetsatane. Mwachitsanzo, kafukufuku adawonetsa kuti kupsinjika komwe kumachulukirachulukira kumachulukirachulukira ndikuthamanga koma kumachepa ndi kuchuluka kwa chakudya. Kukonzekera koyenera, monga kudya kwa 3.6 kg/h pa screw speed ya 95 rpm, kumawonjezera kutentha kwinaku kumachepetsa kusweka kwa ulusi. Zotsatirazi zikuwonetsa kufunikira kolinganiza zinthu izi kuti mukwaniritse bwino extrusion.

Njira Zowongolera Mphamvu ya Shear

Kuwongolera mphamvu yakumeta ubweya ndikofunikira pakuwongolera njira yotulutsa ndikuwonetsetsa kuti zinthu zili bwino. Njira zingapo zingagwiritsidwe ntchito kuwongolera mphamvu yakumeta ubweya mu 2 screw extruder:

- Kusintha Screw Speed: Othandizira amatha kuwonjezera kapena kuchepetsa liwiro la screw kuti asinthe kuchuluka kwa kukameta ubweya ndikukwaniritsa zomwe akufuna.

- Kusintha Screw Design: Kupanga wononga geometry, monga kusintha machulukidwe kapena kuya kwa ndege, kumathandizira kuwongolera bwino ntchito yometa.

- Kugwiritsa Ntchito Zitsanzo Zopatulira Shear: Zitsanzozi zimathandizira kulosera zakuthupi pansi pamikhalidwe yosinthika yometa, zomwe zimathandiza kuwongolera bwino njira. Komabe, kudalira kokha pa zitsanzozi kungayambitse kupeputsa magawo ofunika monga kupanikizika ndi kukhuthala.

- Kukhazikitsa Advanced Monitoring Systems: Kuwunika kwanthawi yeniyeni kwa magawo monga kutentha, kuthamanga, ndi torque kumapereka chidziwitso chofunikira pakuchitapo kanthu. Deta iyi ingagwiritsidwe ntchito kupanga zosintha ndikusunga milingo yabwino kwambiri yamphamvu yakumeta ubweya.

Kafukufuku wasonyeza kuti ntchito ya screw potengera kutentha ndiyofunikira pakuwongolera mphamvu yakumeta ubweya. A recirculation dera mawonekedwe mkati mwa extruder, amene amathandiza kugawa kutentha mofanana ndi kupewa kutenthedwa m'dera. Izi zimatsimikizira kuti polima imasungunuka mofanana, kupititsa patsogolo ntchito yonse ya extrusion.

Impact of Shear Force pa Zida Zakuthupi

Zotsatira pa Kusakaniza ndi Homogeneity

Mphamvu ya kukameta ubweya imakhala ndi gawo lofunikira pakukwaniritsa kusanganikirana kwa yunifolomu ndi homogeneity muzinthu zokonzedwa ndi pulasitiki yamapasa wononga extruder. Kulumikizana pakati pa zomangira ndi mbiya kumapangitsa kukangana, komwe kumathandizira kusakanikirana kwa ma polima ndi zowonjezera. Izi zimatsimikizira kuti chomaliza chikuwonetsa zinthu zofananira pamapangidwe ake.

Maphunziro amphamvu amawunikira mbali zingapo za kumeta ubweya wa ubweya:

| Mbali ya Shear Force Impact | Kufotokozera |

|---|---|

| Kuwonongeka kwa Fiber | Kumeta ubweya wa matrix osungunula kumabweretsa kusweka kwa ulusi, zomwe zimakhudza kapangidwe ka chinthu chomaliza. |

| Kutentha Generation | Pafupifupi 80% ya kutentha komwe kumafunika kusungunuka kumabwera chifukwa cha kukangana chifukwa cha kumeta ubweya pakati pa zomangira ndi mbiya. |

| Kusakaniza Mwachangu | Kapangidwe ka madera osakanikirana okhala ndi zinthu zakutsogolo komanso zobwerera kumbuyo zimakhudza mphamvu yamakasitomala komanso kusakanikirana kokwanira. |

| Kugawira Nthawi Yogona | RTD imakhudza kwambiri mawonekedwe azinthu pozindikira nthawi ya kutentha, kupanikizika, ndi kumeta ubweya. |

Kuonjezera apo, kuwonjezereka kwa liwiro la rotor panthawi ya kusakaniza kwa polypropylene-sisasal kusungunula kumabweretsa kusweka kwa ulusi wambiri, kumapanga utali wochepa wa ulusi. Chodabwitsa ichi, chomwe chimawonedwa mu ulusi wachilengedwe, chimachitika chifukwa chakuti kukameta ubweya kumalekanitsa ulusi womanga mitolo, kuchepetsa m'mimba mwake. Zotsatirazi zikugogomezera kufunikira kokhathamiritsa mphamvu ya shear kuti igwirizane bwino ndi kusakanizika bwino kwa zinthu.

Chikoka pa Thermal Properties ndi Kugawa kwa Kutentha

Kumeta ubweya wa ubweya kumakhudza kwambiri katundu wamafuta ndi kugawa kutentha panthawi ya extrusion. Kukangana kopangidwa ndi zomangira kumatenga pafupifupi 80% ya kutentha komwe kumafunika kusungunula zinthu zapulasitiki. Kugawidwa kwa kutentha kumeneku kumatsimikizira kusungunuka kofanana ndikulepheretsa kutenthedwa kwapadera, komwe kungawononge khalidwe lazinthu.

Mapangidwe a madera osakanikirana a extruder amawonjezera kutentha. Zinthu zopita patsogolo ndi zobwerera m'mbuyo zimapanga mphamvu zamagetsi zomwe zimapangitsa kuti matenthedwe aziyenda bwino. Kugawa nthawi yanyumba (RTD) kumathandizanso kwambiri. Zida zomwe zimakhudzidwa ndi mphamvu zometa ubweya wokhazikika zimatenthedwa mofanana, zomwe zimapangitsa kuti kutentha kuzikhala bwino.

Mwachitsanzo, zoyerekeza manambala zimasonyeza kuti kukameta ubweya mphamvu amakhudza microstructure ya immiscible aloyi pa kusakaniza. Mphamvu izi zimakhudza ma viscosity ratios ndi chipwirikiti, kuwonetsetsa ngakhale kufalitsa kutentha kudutsa zinthuzo. Zotsatirazi zikuwonetsa kufunikira kwa mphamvu yakumeta ubweya posunga kutentha kwapakati panthawi ya extrusion.

Kusintha kwa Katundu Wamakina ndi Mphamvu Zazida

kukameta ubweya mphamvu mwachindunji zimakhudza makina katundu ndi mphamvu extruded zipangizo. Kusiyanasiyana kwa kumeta ubweya wa ubweya kumatha kusintha mawonekedwe a mamolekyu, zomwe zimapangitsa kuti pakhale kusintha kwamphamvu, kulimba, komanso kulimba.

Kafukufuku wa manambala akuwonetsa zotsatirazi:

- Kuchuluka kwa kukameta ubweya wa zitsanzo zamakona olowa kumawonjezeka mosagwirizana ndi kupsinjika kwanthawi zonse, pomwe kumeta ubweya wotsalira kumawonetsa kusagwirizana pang'ono ndi kapangidwe ka mafupa.

- Pakupsinjika kocheperako, zitsanzo zimawonetsa kumeta ubweya wa ubweya, zomwe zimachepetsa kupsinjika kwakukulu. Khalidweli likuwonetsa kugwirizana koyipa pakati pa kusamuka kwabwinobwino komanso kosalekeza.

- Makhalidwe olephera amasiyana ndi ma angles olowa. Magawo atali-ang'ono amawonetsa ming'alu yowongoka ndi yometa ubweya, pomwe madera otsika amawonetsa kulephera kwa kukameta ubweya motsatira njira yakumeta ubweya.

Zotsatirazi zikugogomezera kufunikira kowongolera mphamvu yakumeta ubweya kuti mukwaniritse zomwe mukufuna. Mwachitsanzo, kumeta ubweya wambiri kungayambitse kusweka kwa ulusi, kuchepetsa mphamvu zakuthupi. Mosiyana ndi zimenezi, kukameta ubweya wosakwanira kungayambitse kusakaniza kosakwanira, kusokoneza khalidwe la mankhwala.

Maphunziro Ochitika: Makhalidwe Azinthu Pansi pa Mikhalidwe Yosiyanasiyana ya Kumeta

Kafukufuku wochitika amapereka zidziwitso zofunikira za momwe mphamvu yakumeta ubweya imakhudzira khalidwe lakuthupi. Kafukufuku wa polypropylene-clay nanocomposites akuwonetsa izimapasa wononga extruderskukwaniritsa kubalalitsidwa wapamwamba poyerekeza ndi machitidwe amodzi wononga. Kumeta ubweya wambiri kumawonjezera kutulutsa, kumapangitsa kuti makinawo azitentha komanso kutentha.

Kafukufuku wina wokhudza ulusi wachilengedwe akuwonetsa kuti kumeta ubweya komwe kumagwiritsidwa ntchito pophatikizana kumalekanitsa ulusi womanga mitolo, kumachepetsa m'mimba mwake. Izi zimapangitsa kuti zinthuzo zikhale zofanana koma zimatha kusokoneza kukhulupirika kwake.

M'mafakitale, kukhathamiritsa mphamvu yakumeta ubweya kwatsimikizira kuti ndikofunikira pakupanga zinthu zapamwamba kwambiri. Mwachitsanzo, kusintha screw speed ndi geometry mu pulasitiki mapasa wononga extruder zimatsimikizira yunifolomu kusanganikirana ndi kusasinthasintha katundu katundu. Kafukufukuyu akuwunikira kufunikira kosintha mphamvu ya shear kuzinthu zinazake.

Kukhathamiritsa Njira za Pulasitiki Twin Screw Extruder

Screw Design ndi Kusintha Kusintha

Kukopera screw designndizofunikira pakuwongolera magwiridwe antchito a pulasitiki amapasa wononga extruder. Zosintha za ma screw geometry, monga kukwera, kuzama kwa ndege, ndi mbali ya intermeshing, zimakhudza mwachindunji kupanga kukameta ubweya ndi kayendedwe kazinthu. Mwachitsanzo, zomangira zokhala ndi ndege zozama zimachepetsa kumeta ubweya, pomwe zomangira zolimba zimakulitsa luso losakanikirana.

Othandizira nthawi zambiri amasintha masinthidwe kuti agwirizane ndi zinthu zinazake. Mapulasitiki owoneka bwino amapindula ndi zomangira zomwe zimapangidwa ndi kuya kokulirapo kwa ndege kuti zithandizire kuyenda bwino. Mosiyana ndi izi, zida zotsika kachulukidwe zimafunikira ma angles ocheperako kuti zitsimikizire kumeta kokwanira. Kusintha uku kumapangitsa kuti zinthu zikhale bwino komanso zimachepetsa kugwiritsa ntchito mphamvu panthawi ya extrusion.

Kulinganiza Mphamvu ya Shear ndi Kutentha

Kusunga bwino pakati pa kukameta ubweya wa ubweya ndi kutentha n'kofunika kwambiri kuti tikwaniritse khalidwe lokhazikika la extrusion. Kumeta ubweya wambiri kungayambitse kutentha, pamene kumeta ubweya wosakwanira kungayambitse kusakaniza kosakwanira. Kuwongolera kupanikizika mkati mwa extruder kumagwira ntchito yofunika kwambiri pakuwongolera izi.

Mwachitsanzo, ndondomeko imasonyeza mgwirizano pakati pa kuthamanga ndi kutentha: ∆T (°C) = ∆P (bar) ÷ 2. Kukonza 500 kg / h pa mphamvu ya 40 bar kungawonjezere kutentha kwa 20 ° C. Kuphatikiza pampu ya giya kumachepetsa kuthamanga kwa kutulutsa, kuchepetsa kutentha komanso kuvala zomangira zotulutsa. Kuwongolera kotsekeka kwa loop kumawonjezera kukhazikika kwa extrusion, kuwonetsetsa kugawa kwa kutentha kofanana ndi katundu wabwino kwambiri.

Tailoring Shear Force for Specific Plastic Application

Kusintha mphamvu ya shear kuzinthu zina kumathandizira magwiridwe antchito a zida zapulasitiki. Mwachitsanzo, kuwonjezera mapulasitiki kumagulu a PLA kumathandizira kusinthasintha, kukana kukhudzidwa, komanso makina amakina. Zithunzi za scanning electron microscopy (SEM) zikuwonetsa kuti pulasitiki ya PLA imawonetsa ductility kwambiri poyerekeza ndi zophatikiza zopanda pulasitiki, zomwe zimawonetsa kusakhazikika.

Mayesero a Flexural akuwonetsa kuti zophatikizira zapulasitiki zimakhala ndi zotsika zosinthika modulus, zomwe zikuwonetsa kusinthasintha. Kuphatikiza apo, kuwonjezera kwa plasticizers kumachepetsa kutentha kwa galasi (Tg), kumathandizira kukonza kosavuta. Zosinthazi zikuwonetsa kufunikira kosintha makonda akumeta ubweya kuti akwaniritse zofunikira zapadera zamapulasitiki osiyanasiyana.

Njira Zowunika Nthawi Yeniyeni ndi Njira Zoyezera

Machitidwe owonetsetsa nthawi yeniyeniperekani zidziwitso zamtengo wapatali panjira ya extrusion, zomwe zimathandizira ogwiritsa ntchito kukhathamiritsa mphamvu ya shear bwino. Zomverera zimayezera magawo ofunikira monga kutentha, kuthamanga, ndi torque, zomwe zimapatsa mphamvu zowongolera bwino zomwe zikuchitika.

Njira zowunikira mwaukadaulo, monga makina otsekeka, zimasunga zokhazikika zokhazikika komanso kupewa kusinthasintha komwe kungasokoneze mtundu wazinthu. Machitidwewa amazindikiranso zolakwika pakuyenda kwa zinthu, zomwe zimalola ogwira ntchito kuti asinthe mwamsanga. Pogwiritsa ntchito deta yeniyeni, opanga amaonetsetsa kuti pulasitiki yamapasa wononga extruder imagwira ntchito bwino kwambiri, ikupereka zotulutsa zapamwamba kwambiri.

Mphamvu ya shear imakhalabe mwala wapangodya wa pulasitiki wamapasa wononga, kupanga zinthu zakuthupi monga kusakaniza, kukhazikika kwamafuta, ndi mphamvu zamakina. Kuwongolera mphamvuyi kumawonjezera kukongola kwazinthu komanso ntchito yabwino.

Kupitilira kwatsopano pakuwongolera mphamvu yakumeta ubweya kudzatsegula mwayi watsopano pakukonza pulasitiki. Ofufuza ndi mainjiniya ayenera kufufuza njira zapamwamba kuti athe kukonzanso zotsatira za extrusion.

FAQ

Kodi ntchito yayikulu ya shear force mu twin screw extrusion ndi chiyani?

Mphamvu ya kukameta ubweya imathandizira kusungunuka kwa zinthu, kusakanikirana, ndi homogenization. Imawonetsetsa kukhazikika kwazinthu potengera zinthu zamatenthedwe komanso zamakina panthawi ya extrusion.

Kodi ogwira ntchito angawongolere bwanji mphamvu yakumeta ubweya mu 2 screw extruder?

Othandizira amasintha liwiro la screw, sinthani makonda a screw geometry, ndikuwunika magawo anthawi yeniyeni monga kuthamanga ndi torque kuti muwongolere mphamvu yakumeta ubweya moyenera.

Chifukwa chiyani kulinganiza mphamvu yakumeta ubweya ndi kutentha ndikofunikira?

Kulinganiza kukameta ubweya mphamvu ndi kutenthakumalepheretsa kuwonongeka kwa zinthu, kumatsimikizira kusanganikirana yunifolomu, ndikusunga mikhalidwe yabwino kwambiri ya extrusion chifukwa chapamwamba kwambiri.

Nthawi yotumiza: Jun-11-2025