Makina omangira jakisoni wapulasitiki amasintha bwino pulasitiki yaiwisi kukhala mawonekedwe olondola, ovuta. Njira imeneyi imakhala ndi ubwino wambiri:

- Kupanga magawo ovuta kwambiri olondola kwambiri.

- Kupereka khalidwe losasinthika ndi kubwerezabwereza.

- Kuchepetsa ndalama zopangira popanga zazikulu.

Mapangidwe apamwamba, monga Screw Type Injection Molding Machine ndiScrew Type Injection Molding Machine, onjezerani kuyenda kwa zinthu ndikuwongolera magwiridwe antchito. Kuphatikiza apo, theMakina Omangira Mapiritsi AwirindiScrew Injection Molding Machinekupititsa patsogolo bwino komanso kutulutsa muzopanga.

Jekeseni wa Screw Type Injection Molding Machine

Chigawo chojambulira mu Screw Type Injection Molding Machine chimagwira ntchito yofunika kwambiri pakusintha mapulasitiki aiwisi kukhala osungunuka ndikuwabaya mu nkhungu. Chigawochi chimakhala ndi zigawo zitatu zazikulu: chopukutira, mbiya, ndi makina omangira. Gawo lirilonse limathandizira kuti ntchitoyo ikhale yogwira ntchito komanso yolondola.

Hopper

Hopper imagwira ntchito ngati polowera zinthu zapulasitiki zosaphika. Imagwira ma pellets apulasitiki ndikuwadyetsa mu mbiya kuti apitirize kukonzedwa. Ma hopper amakono nthawi zambiri amakhala ndi zinthu monga zowumitsa zakuthupi kuti achotse chinyezi pama pellets, kuwonetsetsa kusungunuka kwabwino. Pokhalabe ndi zinthu zosasinthika, hopper imathandizira kusinthasintha kosalekeza kwa makina opangira Screw Type Injection Molding Machine.

Mgolo

Mgolowu ndi chipinda cha cylindrical chomwe chimakhala ndi makina omangira. Imatenthetsa ma pellets apulasitiki mpaka kusungunuka kwawo pogwiritsa ntchito magawo angapo otentha. Magawo awa - omwe amagawidwa kukhala chakudya, kumbuyo, pakati, ndi kutsogolo - amalola kuwongolera bwino kutentha, zomwe ndizofunikira kwambiri kuti munthu asungunuke. Kugawa koyenera kwa kutentha mkati mwa mbiya kumateteza zinthu monga ma warpage, kusalongosoka, ndi kuwonongeka kwa zinthu. Kuwongolera mosamalitsa kumeneku kumawonetsetsa kuti Makina a Screw Type Injection Molding Machine amapereka zotulutsa zapamwamba nthawi zonse.

- Kutentha koyenera kwa mbiya ndikofunikira kuti ntchito igwire bwino.

- Zokonda zolakwika zimatha kubweretsa zolakwika pazomaliza.

- Mapangidwe apamwamba amawongolera mphamvu zamagetsi ndikuchepetsa ndalama zogwirira ntchito.

Screw Mechanism

The screw mechanism ndi mtima wa jekeseni. Imazungulira mkati mwa mbiya, kusakaniza ndi kusungunula mapepala apulasitiki pamene ikukankhira zinthu zosungunuka patsogolo. Mapangidwe a screw amakhudza kwambiri kusungunuka ndi jekeseni. Mwachitsanzo, stationaryscrew mapangidweonjezerani pulasitiki powonetsetsa kuti kumeta ubweya kukhale kofanana komanso kuchuluka kwa kuwombera. Kuphatikiza apo, mawonekedwe ngati ma valve a poppet amapereka chiwongolero cholondola pozimitsa nthawi yomweyo screw ikayima.

M'makina amagetsi onse a Screw Type Injection Molding Machines, makina opangira ma screw amapereka mphamvu zosayerekezeka pa liwiro, kuthamanga, ndi malo. Kulondola uku kumachepetsa kusiyanasiyana pakati pa mizunguliro, kuwonetsetsa kuti kudzazidwa kosasintha ndi kukula kwa kuwombera. Kupititsa patsogolo kumeneku sikungowonjezera kusungunuka kwabwino komanso kumapangitsanso kuti ntchito youmba ikhale yabwino.

- Kuphatikizika kwa makina ndi ma robotiki kumawonjezera kutulutsa.

- Mapangidwe a screws osagwiritsa ntchito mphamvu amathandizira kuchepetsa mtengo.

- Kugwiritsa ntchito zinthu mokhazikika kumagwirizana ndi njira zamakono zopangira.

Chigawo chojambulira mu Screw Type Injection Molding Machine chimapereka chitsanzo cha kulumikizana kwaukadaulo wapamwamba komanso kuwongolera molondola. Zigawo zake zimagwirira ntchito limodzi mosasunthika kuti zipereke kupanga kwapamwamba, kothandiza, komanso kodalirika.

Clamping ndi Mold Units

Ma unit clamping ndi nkhungu ndizofunikira kwambiri pamakina opangira jakisoni apulasitiki. Amawonetsetsa kuti nkhungu imakhalabe yotsekedwa bwino panthawi ya jekeseni ndikuthandizira kupanga magawo enieni, apamwamba kwambiri. Magawo awa amakhala ndi nkhungu, ma platens, ndi mota drive, iliyonse imagwira ntchito yosiyana pakuumba.

Nkhungu

Chikombolechi chimagwira ntchito ngati chibowo chapulasitiki chosungunuka. Mapangidwe ake amakhudza mwachindunji ubwino ndi kusasinthasintha kwa mankhwala omaliza.Njira zabwino kwambiri zopangira nkhunguTsimikizani makulidwe a khoma lofanana kuti mupewe zolakwika monga zopindika ndi zozama pakuzizira. Kusintha kosalala pakati pa makulidwe osiyanasiyana, opangidwa ndi chamfers kapena fillets, kumawonjezera kukhulupirika kwamapangidwe.

- Kukula koyenera kwa khoma kumapewa zolakwika zodzikongoletsera monga kupotoza ndi kumira.

- Mphamvu zamapangidwe zimatha kusinthidwa ndi nthiti ndi ma gussets m'malo mowonjezera makulidwe.

- Njira za Design of Experiments (DOE) zimathandizira kuzindikira zolakwika msanga, kuwonetsetsa kuti magwiridwe antchito ndi odalirika.

Mu Screw Type Injection Molding Machine, kulondola kwa nkhungu kumatsimikizira kuti mapangidwe odabwitsa komanso kulolerana kolimba kumachitika. Kuthekera kumeneku kumapangitsa kukhala koyenera kupanga magawo ovuta okhala ndi mtundu wokhazikika.

Mbale

Ma platen ndi mbale zazikulu, zosalala zomwe zimagwira nkhungu pamalo ake ndikugawa mphamvu ya clamping mofanana. Mapangidwe awo ndi kukhulupirika kwawo ndizofunikira kwambiri kuti zisungidwe molingana ndi nkhungu ndikuwonetsetsa kupanikizika kofanana panthawi ya jekeseni. Zofunikira zaukadaulo zomwe zimakhudza magwiridwe antchito a platen ndi monga kulemera, mphamvu yonyamula katundu, komanso kukhathamiritsa kwapangidwe.

| Parameter | Zokhudza Kugwirizana kwa Mold |

|---|---|

| Weight Impact | Zimapanga pafupifupi 70% ya kulemera kwa makina onse, zomwe zimakhudza kukhazikika ndi kuyanjanitsa. |

| Kufunika Kwachuma | Kukonzekera bwino kumachepetsa kugwiritsidwa ntchito kwa zinthu zopangira, kumapangitsa kuti mtengo ukhale wogwira ntchito. |

| Zokhudza Kuchita | Imawonetsetsa kulumikizana koyenera kwa nkhungu ndi kugawa kwamphamvu kofananira, kofunikira pakupanga kwapamwamba. |

| Kukhathamiritsa Kwamapangidwe | Imakulitsa kukula, mawonekedwe, ndi kugawa zinthu kuti zigwirizane bwino. |

| Katundu Wonyamula Mphamvu | Imakulitsa kulimba komanso imathandizira kulumikizana kwa nkhungu pansi pa zovuta zogwirira ntchito. |

Mu Makina Omangira Jakisoni wa Screw Type, ma platen amathandizira kuti makinawo athe kupanga zigawo zolondola kwambiri. Mapangidwe awo olimba amatsimikizira kulimba komanso kugwira ntchito mosasinthasintha, ngakhale pansi pa mphamvu zolimba kwambiri.

Magalimoto Oyendetsa

Kuyendetsa kwa mota kumathandizira makina omangira, kupangitsa nkhungu kutseguka ndikutseka mwatsatanetsatane. Zimagwira ntchito yofunika kwambiri pakusunga liwiro komanso kulondola kwa njira yokhomerera.Magalimoto amakono, makamaka m'makina amagetsi onse, amapereka mphamvu zowongolera pa clamping mphamvu ndi malo. Kulondola kumeneku kumachepetsa kuvala pa nkhungu ndikuchepetsa nthawi yozungulira, kuwongolera magwiridwe antchito.

Magalimoto osagwiritsa ntchito mphamvu amathandiziranso kuti achepetse ndalama komanso kuti azikhala okhazikika. Mwa kukhathamiritsa kugwiritsa ntchito mphamvu, amagwirizana ndi njira zamakono zopangira zomwe zimayika patsogolo udindo wa chilengedwe. Mu Screw Type Injection Molding Machine, galimoto yoyendetsa galimoto imawonetsetsa kuti ikugwira ntchito mopanda msoko, imathandizira kupanga mwachangu popanda kusokoneza mtundu.

Langizo:Kusamalira nthawi zonse kwa galimotoyo kumatha kukulitsa moyo wake ndikuletsa kutsika kosayembekezereka, ndikuwonetsetsa kuti kupangidwa kosalekeza.

Magawo a clamping ndi nkhungu amawonetsa kulumikizana kwa uinjiniya ndi kulondola kwamakina omangira jakisoni apulasitiki. Mapangidwe awo ndi magwiridwe antchito amakhudza mwachindunji luso la makina opangira zida zapamwamba mogwira mtima komanso modalirika.

Njira Zowotchera ndi Kutentha

Njira zowotchera bwino komanso zowongolera kutentha ndizofunikira kuti mukhalebe wabwino komanso wosasinthasintha wa njira zopangira jakisoni wapulasitiki. Machitidwewa amaonetsetsa kuti zinthu zapulasitiki zikufika posungunuka bwino komanso kuti kutentha kwa nkhungu kumakhalabe kokhazikika panthawi yonseyi.

Zotenthetsera Mimbi

Zotenthetsera mipiringidzozimagwira ntchito yofunika kwambiri pakusungunula ma pellets apulasitiki kuti azitha kutentha. Amagwiritsa ntchito malo otenthetsera angapo kuti athe kuwongolera bwino kutentha, komwe ndikofunikira kuti pakhale kusungunuka kofanana. Kuwongolera bwino kutentha kumawonjezera mphamvu zamagetsi ndikuwongolera kutha kwa magawo owumbidwa.

- Kuwongolera bwino kwa kutentha kwa migolo kumalepheretsa kuwonongeka kwa zinthu, makamaka panthawi yotalikirapo yokhalamo.

- Kusunga chandamale kusungunula kutentha kwa pafupifupi 490 ° F kumapangitsa kuti zinthu zisamayende bwino komanso zimachepetsa zolakwika.

- Kusinthasintha kwa kutentha kwa migolo kungawononge khalidwe lazinthu, zomwe zimapangitsa kuti kuyang'anitsitsa ndikofunikira.

Mapangidwe apamwamba a migolo nthawi zambiri amaphatikiza zinthu zotenthetsera zowotcha mphamvu, kuchepetsa ndalama zogwirira ntchito ndikusunga magwiridwe antchito apamwamba. Zinthu izi zimagwirizana ndi njira zamakono zopangira zomwe zimayika patsogolo kukhazikika komanso kuchita bwino.

Zotenthetsera Mold

Zotenthetsera nkhungu zimawongolera kutentha kwa nkhungu, kuwonetsetsa kuti gawoli likuyenda bwino komanso kuchepetsa nthawi yozungulira. Kuchuluka kwa zinthu za nkhungu kumakhudza kwambiri kutentha kwa kutentha. Zigawo zokhuthala zimasunga kutentha kwanthawi yayitali, pomwe zocheperako zimazizira kwambiri. Kusintha makonda a chotenthetsera cha nkhungu potengera makulidwe azinthu kumalepheretsa zovuta ngati warping ndikuwonetsetsa kugawa kwa kutentha kofanana.

Njira za Scientific Molding zimapititsa patsogolo ntchito ya chotenthetsera cha nkhungu. Njirazi zimachepetsa nthawi yoyambira, zimachepetsa kuchulukirachulukira, ndikuwonjezera kusasinthika kwazinthu. Posunga kutentha kwa nkhungu moyenera, opanga amapeza phindu lalikulu komanso kuchita bwino.

Njira Yowongolera Kutentha

Thenjira yoyendetsera kutenthazimatsimikizira kukhazikika ndi kulondola panthawi youmba. Njira zotsogola, monga kuwongolera kosinthika kwaukadaulo, kuphatikiza kuwongolera kwachikhalidwe kwa PID ndi malingaliro osamveka bwino kuti muwonjezere kutentha kwa migolo. Njirayi imachepetsa kugwedezeka ndi kugwedezeka, kupititsa patsogolo machitidwe onse.

| Njira Yowongolera | Kufotokozera |

|---|---|

| Katswiri Wosinthika Wosakhazikika Wowongolera | Imaphatikiza kuwongolera kwaukadaulo, kosavuta, ndi PID kuti ukhale wokhazikika komanso wolondola. |

| PID Control | Traditional njira sachedwa overshoot ndi oscillation. |

| Model Predictive Control | Imalondola liwiro la jakisoni, kuwongolera kulondola pakuumba. |

Mitundu yophunzirira pamakina, monga ma aligorivimu a m'nkhalango, imathandizanso kuti mphamvu ziziyenda bwino pozindikira zinthu zazikulu zomwe zimakhudza kugwiritsa ntchito mphamvu. Zatsopanozi zimathandiza opanga kulinganiza kugwiritsa ntchito mphamvu ndi mtundu wina, kupititsa patsogolo kukhazikika kwa ntchito zoumba jekeseni.

Magawo a Hydraulic ndi Control

Ma hydraulic ndi control unit ndi zinthu zofunika kwambiri pamakina opangira jakisoni apulasitiki. Machitidwewa amagwirira ntchito limodzi kuti awonetsetse kugwira ntchito moyenera, kuchita bwino, komansokusasinthasintha mankhwala khalidwe.

Hydraulic System

Dongosolo la hydraulic limathandizira kusuntha kwa jakisoni ndi njira zomangira. Amapanga mphamvu yofunikira kubaya pulasitiki yosungunuka mu nkhungu ndikusunga kukakamiza kwa clamping panthawi yakuumba. Mapampu a hydraulic, mavavu, ndi masilindala amapanga maziko a dongosolo lino, akupereka magwiridwe antchito owongolera komanso odalirika.

Makina amakono a hydraulic amaphatikiza matekinoloje apamwamba kutionjezerani mphamvu. Mapampu osunthika osinthika amasintha kuchuluka kwamayendedwe potengera zosowa zamakina, kuchepetsa kugwiritsa ntchito mphamvu. Kuphatikiza apo, ma valve ofananira amapereka kuwongolera kolondola kwa kuthamanga ndi kuthamanga, kuonetsetsa kuti kuyenda bwino komanso kolondola. Zinthu zimenezi zimathandiza kuti makinawa azipanga zinthu zamtengo wapatali komanso zotayirira zochepa.

Langizo:Kukonza pafupipafupi kwa zida za hydraulic, monga kuyang'ana ngati kutayikira ndikuwunika momwe mafuta alili, kumatha kukulitsa moyo wadongosolo ndikuletsa kutsika.

Gawo lowongolera

Gulu lowongolera limakhala ngati ubongo wa makina opangira jakisoni. Imayang'anira ndikuwongolera ntchito zonse zamakina, ndikuwonetsetsa kuti zikuyenda bwino. Wokhala ndi masensa, gulu lowongolera limasonkhanitsa deta yeniyeni pazigawo zofunika kwambiri monga kutentha, kupanikizika, ndi udindo. Mwachitsanzo:

- Zomverera zimayezera ndikupereka ndemanga pa kutentha ndi kuthamanga.

- Masensa a membrane a mphete amatsimikizira miyeso yolondola ya malo pogwiritsa ntchito ma cell a strain gauge.

Makina ophunzirira makina ophatikizidwa mu gulu lowongolera amapititsa patsogolo luso lake. Zitsanzozi zimaneneratu zamtundu wamtundu wina monga kupsinjika kwa zokolola ndi modulus, kukhathamiritsa makonzedwe anjira kuti akhale ndi zotsatira zofananira. Zotsatira zoyesera zimatsimikizira zitsanzozi poyerekezera zomwe zanenedweratu ndi zotsatira zenizeni, kutsimikizira kuti zimagwira ntchito bwino pakupanga bwino.

Magawo a hydraulic ndi control unit amawonetsa kulumikizana kwaukadaulo wamakina ndi digito, kuwonetsetsa kulondola komanso kudalirika pamakina omangira jakisoni apulasitiki.

Njira Zodyetsera ndi Kutulutsa

Kudyetsa Unit

Thechakudya chamaguluzimatsimikizira kupezeka kosasinthika kwa zinthu zapulasitiki zosaphika ku makina opangira jekeseni. Kawirikawiri zimakhala ndi hopper ndi wononga chakudya. Chophimbacho chimasunga mapepala apulasitiki ndikuwatsogolera mu mbiya, momwe zinthuzo zimasungunuka. Mphamvu yokoka ndi kugwedezeka koyendetsedwa kumathandizira kuyenda bwino kwa pellets, kuteteza kutsekeka kapena kusokoneza panthawi yopanga.

Malo odyetsera amakono nthawi zambiri amakhala ndi zinthu zapamwamba monga zowumitsa zakuthupi. Machitidwewa amachotsa chinyezi kuchokera ku pellets, zomwe ndizofunikira kwambiri kuti zikhalebe zosungunuka komanso kuteteza zolakwika mu mankhwala omaliza. Kuphatikiza apo, makina odyetsera okhawo amawonjezera mphamvu mwa kulunzanitsa kupezeka kwa zinthu ndi liwiro la makinawo. Kulunzanitsa kumeneku kumachepetsa kuonongeka kwa zinthu ndikuwonetsetsa kuti zinthu sizingasokonezeke.

Ejection Unit

Theejection unitimagwira ntchito yofunika kwambiri pochotsa gawo lopangidwa mu nkhungu pambuyo pozizira. Imagwiritsa ntchito ma ejector pin, mbale, kapena kuphulika kwa mpweya kuti itulutse zomwe zatsirizidwa popanda kuwononga. Kulondola pa nthawi yotulutsa ejection ndi mphamvu ndizofunikira kuti musunge kukhulupirika kwa gawo lowumbidwa ndikupewa zolakwika monga kupindika kapena kusweka.

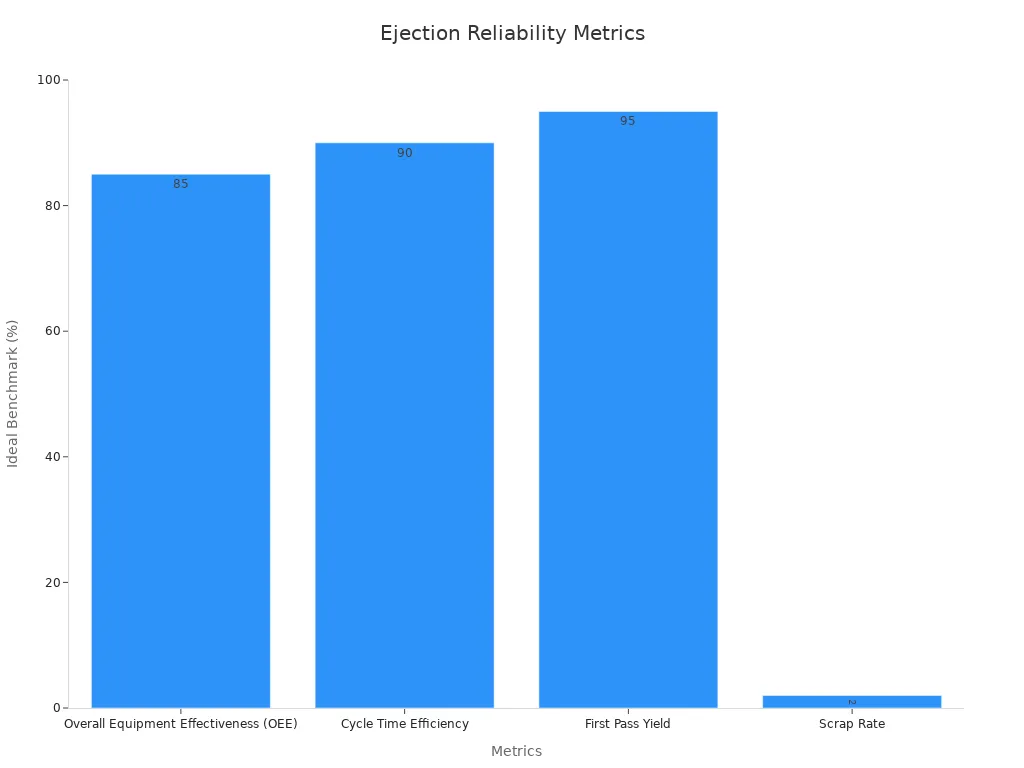

Magawo odalirika a ejection amachepetsa kwambiri kutsika kwa nthawi yopanga. Ma metrics monga Kukwanira Kwa Zida Zonse (OEE), Cycle Time Efficiency, ndi First Pass Yield (FPY) amatsimikizira ntchito yawo. Mwachitsanzo:

| Metric | Kufotokozera | Benchmark yabwino |

|---|---|---|

| Kuchita Mwachangu kwa Zida Zonse (OEE) | Amayesa kupanga bwino; kuwerengeredwa kuchokera pa kupezeka, kachitidwe, ndi mtundu. | ~85% |

| Kuchita Bwino kwa Nthawi Yozungulira | Imatsata nthawi kuti mumalize kuzungulira kumodzi; nthawi zochepa zimawonjezera kutulutsa. | 90% kapena kuposa |

| First Pass Yield (FPY) | Peresenti ya mankhwala opangidwa molondola nthawi yoyamba; mitengo yapamwamba imasonyeza njira zogwira mtima. | > 95% |

| Mtengo wa Zida | Peresenti ya zinthu zotayidwa; mitengo yotsika imakulitsa phindu. | <2% |

Machitidwe apamwamba a ejection amaphatikiza masensa kuti aziyang'anira ndikusintha mphamvu ya ejection mwamphamvu. Zatsopanozi zimatsimikizira kusasinthika kwa gawo ndikuchepetsa kuvala pa nkhungu ndi zida zamakina. Kusamalira nthawi zonse kwa ejection unit kumawonjezera kudalirika kwake ndikuwonjezera moyo wake wogwira ntchito.

Makina opangira jakisoni apulasitiki amaphatikiza zida zapamwamba kuti apereke ntchito yapadera. Gawo lililonse limathandizira kupanga bwino, kudalirika, komanso kudalirika. Kudziwa bwino machitidwewa kumatsimikizira zotsatira zabwino.

| Metric | Kufotokozera |

|---|---|

| Kuchita Mwachangu | Zimawonetsa momwe zida zopangira zimasinthidwa kukhala zomalizidwa. |

| Mtengo wa Zida | Imawonetsa kuchuluka kwa zopanga zomwe sizikugwirizana ndi miyezo yabwino. |

| Kusintha kwa Makina | Imakhudza magwiridwe antchito komanso ndalama zogwirira ntchito, zofunika kuti pakhale phindu. |

Kumvetsetsa ma metric awa kumawunikira gawo la makina kuti akwaniritse zotulutsa zokhazikika, zapamwamba kwambiri.

FAQ

1. Ndi zinthu ziti zomwe zingagwiritsidwe ntchito pamakina opangira jakisoni apulasitiki?

Makina omangira jakisoni apulasitiki amapangira ma thermoplastics ngati ABS, polypropylene, ndi nayiloni. Amagwiranso ntchito mapulasitiki a engineering monga polycarbonate ndi PEEK.

2. Kodi kutentha kumakhudza bwanji khalidwe la mankhwala?

Kuwongolera kutentha kumatsimikizira kusungunuka kofanana, kumachepetsa zolakwika, ndikuwonjezera kulondola kwa mawonekedwe. Zimalepheretsa kuwonongeka kwa zinthu panthawi yowonjezereka yokonza.

3. Ndi njira ziti zosamalira zomwe zimakulitsa magwiridwe antchito a makina?

Kupaka mafuta pafupipafupi, kuwunika kwa hydraulic system, ndi kuyeretsa malo odyetserako kumalepheretsa kutha komanso kutha. Zowunikira zowunikira zimatsimikizira kugwira ntchito kosasinthasintha komanso kumawonjezera moyo wa makina.

Nthawi yotumiza: May-28-2025