Kulephera kwa mbiya ya Extruder nthawi zambiri kumawoneka ngati nkhani zakudya, kutentha kwambiri, kuvala zowononga, zovuta zosakanikirana, kuipitsidwa kwa migolo, kapena phokoso lachilendo.

1. Zovala za screw element zimachepetsa kudyetsa.

2. Kuchulukitsitsa kuchokera ku chakudya chowonjezera kapena zinthu zakunja kungayambitse kuwonongeka.

3. Kuwonongeka kwa heater ndi kusalinganika molakwika kumabweretsa kuwonongeka.

Kuthetsa mavuto mwachangu komanso kuwunika pafupipafupi kumathandiza katswiri wotulutsaalloy screw mbiyakuchita bwino, kuchepetsa nthawi yopuma, ndi kusunga mankhwala khalidwe mkulu.Alloy Extruder Screw Barrel FactoriesndiAlloy Extruder Screw Barrel Factoryperekani zowunikira pafupipafupi pa Alloy Screw Barrel iliyonse.

Kulephera kwa Common Extruder Screw Barrel

Kudyetsa Mavuto

Nkhani zodyetsa nthawi zambiri zimasokoneza njira ya extrusion. Ogwiritsa ntchito amatha kuona kuti extruder ikusiya kudya moyenera, imavutikira kukankha zinthu, kapena imatulutsa phokoso lakupera ndi kukanda. Zizindikirozi nthawi zambiri zimaloza kutsekeka, kutsekeka kwa zinthu, kapena kutuluka kwa zinthu zosagwirizana. Ma abrasive fillers ngati magalasi ulusi kapena calcium carbonate amatha kulowa m'gawo la chakudya, kupangitsa mphamvu zam'mbali zomwe zimakankhira screw mumgolo.

Kutentha kwambiri

Kutentha kwambiri kumakhalabe vuto pafupipafupi mu migolo ya extruder screw. Kutentha kwambiri, kutentha kwa silinda kosiyana, ndi kutsekeka kosakwanira kumapangitsa kuti kutentha kuwonongeke. Pamene mbiya ikuwotcha mosiyanasiyana, imakula ndikumangirira, zomwe zimatha kuwononga wononga ndi mbiya. Kuwongolera kutentha kosasinthasintha komanso kuzizira koyenera kumathandiza kupewa izi.

Screw Wear ndi Kuwonongeka

Zovala za screw zimawoneka ngati kuchepa kwa mphamvu, kuchuluka kwa mphamvu zogwiritsira ntchito mphamvu, komanso kufunikira kwa zowonjezera zowonjezera. Oyendetsa amatha kununkhiza zinthu zowotcha kapena kuwona zinthu zomwe zikusungidwa m'malo odyetserako chakudya. Nthawi zambiri kuvala kumachitika m'madera omwe ali ndi mphamvu komanso kutentha kwambiri, makamaka pokonza zinthu zowononga kapena zowononga. Kusakhazikika bwino kapena mphamvu zamakina zimatha kukulitsa kuwonongeka.

Mavuto Osakaniza Zinthu

Mavuto osakanikirana amayambitsa zida zosakanizidwa bwino komanso kusagwirizana kwazinthu. Kudzaza kosakwanira kwa extruder, kuyeza ndi kutsika kwapansi kumbuyo, kumabweretsa kutulutsa kosasunthika komanso kupatuka kwamphamvu. Kusakaniza kosakwanira kungayambitsenso kusweka kwa unyolo wa polima, zomwe zimakhudza mphamvu ya chinthu chomaliza ndi mawonekedwe ake.

Kuipitsidwa kwa Mimbi

Kuipitsidwa kwa migolo kumachokera ku ma resin otsalira, ma depositi amtundu, zinthu za carbonized, ndi tinthu tating'ono tolimba. Zoyipa izi zimayambitsa kuyabwa, kumamatira, ndi dzimbiri, zomwe zimapangitsa kuti pakhale kukhathamira komanso kutsika kwa makina pafupipafupi. Kutsuka pafupipafupi ndi mankhwala oyenera kumathandizira kuti asamangidwe komanso kumapangitsa kuti makina azigwira bwino ntchito.

Phokoso kapena Kugwedezeka Kwachilendo

| Phokoso/Kugwedezeka | Chifukwa Chotheka | Tanthauzo Lake |

|---|---|---|

| Kugogoda phokoso | Kusalinganika molakwika kwa mbiya ndi screw | Kupsyinjika ndi kuvala mofulumira |

| Kugwedezeka | Zovala zomangika kapena zolumikizana | Kuvala msanga komanso kuthamanga kwa wononga kosagwirizana |

| Kugwedezeka kwachilendo | Kuwonongeka kozama kapena kuwonongeka kwa makina | Chenjezo loyambirira la kulephera kwakukulu |

Phokoso ndi kunjenjemera kosazolowereka kumasonyeza kusalondolera bwino, mayendedwe otha, kapena kuvala kwambiri mkati. Kuzindikira msanga kumathandiza kupewa kuwonongeka kwakukulu ndi kukonza zodula.

Chifukwa Chake Zolephera Izi Zimachitika

Zoyambitsa Zokhudzana ndi Zakuthupi

Kusankha kwazinthu kumakhala ndi gawo lofunikira pakukhazikika kwa migolo ya extruder screw. Makalasi ena achitsulo, makamaka omwe ali ndi mpweya wambiri, amatha kukhala ndi zilema zowotcherera ngati ma pinholes ndi pores. Zowonongeka izi zimakhala ngati zopanikizika ndipo zimatha kuyambitsa ming'alu panthawi ya ntchito. Zitsulo zosakanizidwa bwino ndi kutentha kwakukulu ndi okosijeni zimalepheranso mofulumira pansi pa matenthedwe a extrusion. Kafukufuku wazitsulo amasonyeza kuti ming'alu imayambira pamalo ofookawa ndipo imakula chifukwa cha kutentha ndi kuzizira mobwerezabwereza.

| Chifukwa Chokhudzana ndi Zinthu Zakuthupi | Kufotokozera ndi Zotsatira zake | Malangizo |

|---|---|---|

| High carbon steel | Kuwonongeka kwa weld, kupsinjika maganizo | Gwiritsani ntchito zitsulo za carbon low, low alloy steels |

| Zoyipa za kutentha kwambiri | Ming'alu ya kutopa kwamafuta | Sankhani zitsulo zokhala ndi ma alloying abwinoko |

Kutopa kwamafuta ndi machitidwe oziziritsa osayenera kumawonjezera chiopsezo cha kulephera.

Kuvala Kwamakina ndi Kung'ambika

Kuvala kwamakina kumachitika pamene zomangira zimazungulira mkati mwa mbiya. Kukangana kumachepetsa m'mimba mwake pang'onopang'ono ndikukulitsa mkati mwa mbiyayo. Chilolezo chowonjezerekachi chimapangitsa kuti zinthu zitheke, zomwe zimachepetsa kupanga komanso kumawonjezera nthawi yomwe imakhala mkati. Kukhala kwakutali kungapangitse mapulasitiki kusweka, kutulutsa mpweya womwe umathandizira kuti dzimbiri. Ma abrasive fillers, tinthu tachitsulo, komanso kuthamanga kwambiri kumawonjezeranso kuvala ndipo kumatha kuthyola wononga.

| Mbali | Kufotokozera |

|---|---|

| Valani makina | Kukhumudwa kumawonjezera kukhumudwa |

| Zotsatira zake | Kutayikira kwazinthu, kutulutsa kochepa |

| Zinthu zowononga | Zodzaza ndi particles zimayambitsa kuwonongeka mwadzidzidzi |

Kagwiritsidwe Ntchito

Zinthu zina zogwirira ntchito zimapangitsa kuti zolephera zitheke. Kutentha kosayenera kungayambitse kutentha kapena kutentha kosafanana, zomwe zimawononga wononga ndi mbiya. Kukonza zinthu zonyansa kapena zoipitsidwa, kusamalidwa bwino kwapulasitiki, komanso kugwiritsa ntchito nthawi yayitali kumawonjezera kuvala. Zovuta zamafuta ndi zolakwika pakuyika, monga kusanja bwino kapena ma bolt otayirira, zimatha kubweretsa phokoso lachilendo, kugwedezeka, komanso kusweka kwa screw.

- Kutsekeka kwa migolo chifukwa cha zonyansa kapena kusakanizika koyipa

- Kulephera kuwongolera kutentha

- Valani kuchokera ku kugwiritsidwa ntchito kwa nthawi yayitali ndi zida zowononga

- Zolakwika zamafuta ndi kukhazikitsa

Kuyang'anira nthawi zonse ndikukhazikitsa moyenera kumathandiza kuchepetsa ngozizi ndikuwonjezera moyo wa zida.

Mayankho a Gawo ndi Gawo Pakulephera Kulikonse

Kukonza Nkhani Zodyetsa

Njira yokhazikika imathandiza ogwira ntchito kuzindikira ndi kuthetsa nkhani zodyetsera m'migolo ya extruder screw. Njira zotsatirazi zikutsogolerani kuthetsa mavuto kuchokera kumacheke osavuta kupita kumayendedwe aukadaulo:

- Onetsetsani kuti filament kapena spool yakuthupi imamasuka momasuka popanda chopinga chilichonse.

- Yang'anani chubu la PTFE kuti muwone zizindikiro zakuwonongeka, zokopa, kapena malo osayenera.

- Yang'anani pa nozzle yotentha ngati ma clogs. Gwiritsani ntchito njira zoyeretsera monga zokoka zozizira kuti muchotse zotchinga.

- Yang'anani zida za extruder zomwe zimavalidwa kapena zomangira zomwe zingakhudze kugwira kwazinthu.

- Tsimikizirani mtundu wa filament kapena zopangira ndikutsimikizira zosintha zolondola.

- Yezerani kukula kwa filament ndikusintha chochulukira chowonjezera ngati pakufunika.

- Wonjezerani kutentha kwa extruder ngati zinthu sizikuyenda bwino.

- Sanjani extruder kuonetsetsa kuyenda moyenera zinthu.

Othandizira ayeneranso:

- Tsukani zinthu zotulutsa kunja bwino mukatha kupanga chilichonse kuti zisamangidwe.

- Sungani zida zamakina oyendetsa, kuphatikiza mafuta a gearbox, mkhalidwe wamagalimoto, kulimba kwa lamba, ndi mafuta onyamula.

- Konzani zipangizo musanapange potsimikizira ndondomeko ndi kuyeretsa njira zodyetsera.

- Pang'onopang'ono onjezerani kuchuluka kwa chakudya ndikuwunika kuthamanga ndi kutentha kwa extrusion yokhazikika.

Kuyang'anitsitsa nthawi zonse ndikusintha mosamalitsa njira zodyetserako kumathandizira kuti zinthu zisamayende bwino ndikupewa kuchepa kwa nthawi.

Kuthana ndi Kutentha Kwambiri

Kutentha kwambiri kumatha kuwononga screw ndi mbiya, kotero oyendetsa amayenera kuchitapo kanthu mwachangu zizindikiro zikawoneka. Njira zotsatirazi zimapereka njira yomveka yodziwira ndikuwongolera kutentha kwambiri:

- Chepetsani kutentha kosungunuka ngati kuwonongeka kwa polima kapena kutenthedwa kwapezeka.

- Yang'anani kuyika kwa thermocouple ndikuwonetsetsa kuti zowongolera zowotchera zimapereka kuwerenga kolondola.

- Yang'anani zowononga za extruder ngati zatha kapena kuwonongeka ndikuyesa kukula kwake.

- Yang'anani mbiya ya extruder kuti yatha kapena kuwonongeka ndikuyesa m'mimba mwake.

- Yang'anani kuipitsidwa kapena zinthu zakunja mu utomoni ndi makina ogwirira ntchito.

- Chepetsani kutentha kwa mbiya ngati kusinthika kapena kuyaka kukuwonetsa kutentha kwambiri.

- Yang'anirani ndikusintha kutentha kwa mbiya kuti mupewe kutenthedwa.

- Kuchepetsa liwiro la wononga kuti muchepetse kutentha.

- Sinthani ma screw element kuti muchepetse kumeta ubweya ngati kuli kofunikira.

- Gwiritsani ntchito njira zoziziritsira kunja kwa zinthu zomwe sizimva kutentha.

Kuyang'anitsitsa mosamala ndi kusintha kwa kayendetsedwe ka kutentha kumateteza zipangizo ndikuonetsetsa kuti zinthu zili bwino.

Kukonza kapena Kusintha Screws Zowonongeka

Pa nthawi yakekukonza kapena kusintha zomangira zothaimabwezeretsa magwiridwe antchito abwino ndikuletsa kutsika mtengo. Zochita zabwino zamakampani ndi:

- Gwiritsani ntchito kukonza moyenera ndikumanganso kuti mubwezeretse zomangira kuzomwe zidakhazikitsidwa kale.

- Bwezerani zomangira pamene kuvala kupyola malire ovomerezeka, chifukwa ngakhale kuvala kochepa kumatha kuchepetsa mphamvu ndi 50%.

- Ganizirani njira zokonzera zotsika mtengo, zomwe zimatha kusunga mpaka 40% poyerekeza ndi zomangira zatsopano.

- Ikani zida zapamwamba monga tungsten carbide zolimba kapena chrome yolimba ya mafakitale kuti muwonjezere kukana.

- Gwiritsani ntchito njira zokonzera monga re-chroming, nitriding, kapena hardfacing kuti muwonjezere moyo wa screw.

- Sungani kutalika kwa ndege panthawi yomanganso kuti mulole kukonzanso kangapo.

- Yang'anirani ma gearbox ndi ma unit thrust kuti muzitha kudzoza bwino komanso kutentha kokhazikika.

- Bweretsani mafuta a lube ndi zosefera pakapita miyezi 6-12 ndikuwunika magiya omwe amavala.

- Yendetsani tsiku ndi tsiku ma v-malamba ndikuwunika kuchuluka kwa magalimoto kuti muwone ngati akuvala.

- Konzani nthawi yopuma yokonzekera miyezi ingapo iliyonse, kutengera momwe ntchito ikugwirira ntchito.

- Bwezerani mbali zong'ambika monga zotsekera ndi zomangira migolo mosamala.

Kuphunzitsidwa kwa oyendetsa ndi kuyang'anira akatswiri nthawi zonse kumatsimikizira kuzindikira kwachangu komanso kumathandiza kupewa kulephera koopsa.

Kupititsa patsogolo Kusakaniza Kwazinthu

Kusakanikirana kosasinthasintha kwazinthu kumatsimikizira zinthu zapamwamba kwambiri komanso kutulutsa kokhazikika. Othandizira amatha kusintha kusakaniza potsatira izi:

- Konzani zomangira zomangira pophatikiza sikona wamkulu wotuluka ndi zomangira zazitali kunsi kwa chodzaza. Izi zimasunga kusungunuka kwamadzi ndikukulitsa voliyumu yaulere pakulowa kwa filler.

- Onetsetsani kuti pali kuthekera kolowera pafupi ndi chodzaza kuti mpweya utuluke popanda kutaya zinthu.

- Chepetsani kutalika kwa dontho la feeder kuti mupewe kufota ndikusunga kachulukidwe kambiri.

- Gwiritsani ntchito chipwirikiti choyenera cha feeder kuti musatenge mpweya.

- Yendetsani ndi kupukuta ma hopper onse ndi ma chute kuti muteteze kuchulukira kwa magetsi osasunthika ndikuyika.

- Gwiritsirani ntchito majekeseni a mpweya kapena ma hopper vibrator kuti muthyole minyewa.

- Tsukani ndi kutsuka chotulukapo nthawi zambiri pogwiritsa ntchito zotsuka ndi mawotchi. Sinthani liwiro la screw potsuka kuti muyeretse bwino.

- Konzani zosintha zopanga bwino poyendetsa zinthu kuti muchepetse ukhondo ndikupanga njira zoyeretsera zolembedwa.

- Tsatirani njira zoyenera zotenthetsera ndi kuziziritsa kuti mupewe kuphika polima ndi carbonization.

- Yang'anirani zizindikiro zazikuluzikulu za ndondomeko monga momwe zimapangidwira komanso kugwiritsa ntchito mphamvu kuti muthe kusakaniza bwino.

Kuyeretsa nthawi zonse ndi kuyang'anira ndondomeko kumathandiza kusunga kusakaniza kosasintha ndikupewa zolakwika.

Kuyeretsa Mimbi ya Kuipitsidwa

Njira zoyeretsera zogwira mtima zimachotsa kuipitsidwa kwa migolo ndikuwonjezera moyo wa zida. Othandizira ayenera:

- Gwiritsani ntchito makina otsuka ndi maburashi ndi nsalu kuti muchotse zotsalira.

- Ikani mankhwala oyeretsera ndi mankhwala oyeretsera opangidwira mapulasitiki enieni ndi dongosolo la extrusion.

- Chitani chithandizo chowongolera kutentha kwa kuipitsidwa kwambiri kuti muchepetse kuchulukana kouma.

- Yang'anani ndikuyeretsa chilichonse chikasintha kapena pakapezeka kuti kachilomboka kapezeka.

- Khalani ndi dongosolo lodzitetezera lomwe limaphatikizapo kuyeretsa zomangira, mbiya, hotrunner, ndi makina ozizira.

- Tsekani makina panthawi yotseka kuti muteteze kuipitsidwa ndi kuwonongeka.

- Gwiritsani ntchito zida zapadera zoyeretsera zomangira m'malo mwa zida zapulasitiki.

- Tsatirani zokonda zamakina zomwe zimalimbikitsidwa ndi othandizira oyeretsa, monga kuthamanga kwa screw ndi kupanikizika kumbuyo.

- Pakuipitsidwa kwamakani, onjezani kutentha pakutsuka kapena kutsuka ndi HDPE kapena PP.

Kuyeretsa pafupipafupi komanso mokwanira kumachepetsa kutsika, kumachepetsa zinyalala, komanso kumateteza zida kuti zisawonongeke kwa nthawi yayitali.

Kuthetsa Phokoso ndi Kugwedezeka

Phokoso kapena kugwedezeka kwachilendo nthawi zambiri kumawonetsa zovuta zamakina. Othandizira amatha kuthetsa mavutowa ndi:

- Kuwona kusalumikizana bwino pakati pa screw ndi mbiya.

- Kuyang'ana ma bearings ndi ma couplings ngati akuwonongeka kapena kuwonongeka.

- Kumvetsera phokoso lachilendo panthawi yogwira ntchito ndikuzindikira komwe akuchokera.

- Kuyang'anira grooving mozama kapena kuwonongeka kwa makina mkati mwa mbiya.

- Kuwonetsetsa kuti zomangira zonse zikumizidwa bwino koma osamizidwa mopitilira muyeso.

- Kupaka mbali zosuntha molingana ndi malangizo a wopanga.

- Kukonza zoyendera akatswiri nthawi ndi nthawi kuti muzindikire zizindikiro zoyamba kutha.

- Kusintha mbali zong'ambika kapena zowonongeka monga ma bearing, ma couplings, ndi zisindikizo mwachangu.

Kuzindikira koyambirira komanso kuchitapo kanthu mwachangu kumalepheretsa kuwonongeka kwakukulu ndikusunga njira yotulutsiramo ntchito bwino.

Kusamalira Kuteteza ndi Njira Zabwino Kwambiri

Njira Zoyendera Nthawi Zonse

Kuyendera mwachizolowezikupanga msana wa odalirika extruder ntchito. Ogwiritsa ntchito amayenera kuyang'ana screw ndi mbiya tsiku lililonse kuti awoneke kapena zotsalira. Kuyeretsa ndi nsalu yopanda lint ndi chinthu choyenera kumakhala kovomerezeka tsiku lililonse. Kuyesa kwa magwiridwe antchito ndikusintha kumathandizira kuti zinthu zizikhala bwino. Chaka ndi chaka, magulu amayenera kuyeza kukula kwa sikonawu kunja kwake ndi kukula kwake kwa mbiya kuti ayang'anire kavalidwe. Kuyang'ana mabawuti otenthetsera mbiya ngati akulimba komanso kulumikizana koyenera miyezi 12 iliyonse kumatsimikizira kutentha kosasintha. Opanga ambiri amapereka mndandanda wa magwiridwe antchito a kotala kuti athandizire magulu kutsatira miyezo ya OEM.

| Malo Ogwirira Ntchito | Kufotokozera Ntchito | pafupipafupi | Zofunika Kwambiri | Zovomerezeka |

|---|---|---|---|---|

| Mgolo ndi Screw | Yang'anirani zizindikiro za kutha ndi kung'ambika | Tsiku ndi tsiku | Yapakati/Yotsika | No |

| Mgolo ndi Screw | Tsukani pogwiritsa ntchito nsalu yopanda lint komanso chinthu choyenera | Tsiku ndi tsiku | Wapamwamba | Inde |

| Mgolo ndi Screw | Kuyesa magwiridwe antchito ndikusintha ngati kuli kofunikira | Tsiku ndi tsiku | Wapamwamba | Inde |

| Screw ndi Barrel | Yesani screw ndi mbiya diameters | Chaka chilichonse | Wapamwamba | Inde |

| Maboti a Heater a Barrel | Onani kulimba komanso kulumikizana kwa chotenthetsera | 12 miyezi | Wapamwamba | Inde |

Njira Zoyeretsera Zoyenera

Kuyeretsa moyenera kumalepheretsa kuipitsidwa komanso kumatalikitsa moyo wa zida. Ogwiritsa ntchito amayenera kutsuka chotuluka pamtundu uliwonse kapena kusintha kwazinthu. Kwa nthawi yayitali, kuyeretsa nthawi ndi nthawi kumapewa ma depositi a kaboni ndi kusanjika. Kuyeretsa kumaphatikizapo kuchepetsa kuthamanga kwa screw, kuyika mbiya mpaka 400 ° F, ndikuchotsa kufa ngati kuli kofunikira. Kuyeretsa wononga ndi zida zamkuwa ndikupukuta ndi gauze yamkuwa kumachotsa zotsalira bwinobwino. Kugwiritsa ntchito stearic acid flakes kumathandizira kukweza madipoziti amakani. Pambuyo poyeretsa, mafuta opepuka kapena plating ya chrome amateteza wononga ku dzimbiri. Osagwiritsa ntchito zida zachitsulo kapena nyali za acetylene, chifukwa zimatha kuwononga phula.

Zopangira Mafuta ndi Kuziziritsa

Kupaka mafuta ndi kuziziritsa koyenera kumapangitsa kuti extruder ikuyenda bwino. Oyendetsa agwiritse ntchito mafuta opangira kutentha kwambiri komanso kupanikizika kwambiri. Kuwunika pafupipafupi komanso kusintha kwa makina opaka mafuta kumatsimikizira kuti magawo onse osuntha amalandira chitetezo chokwanira. Kuyang'anira kuchuluka kwa mafuta ndi kuwonjezeranso ngati pakufunika kumalepheretsa kuuma. Makina apamwamba owongolera kutentha, monga ma thermocouples ndi owongolera a PID, amathandizira kusunga kutentha koyenera. Kugwiritsira ntchito madzi osungunula m'matangi ozizirira kumalepheretsa kukula komanso kusunga kuziziritsa bwino. Magulu ayenera kuyang'anira kuchuluka kwa madzi ndikusintha madzi ngati makulitsidwe awoneka.

Kupaka mafuta mosasinthasintha komanso kuziziritsa kumachepetsa kukangana, kuletsa kutenthedwa, komanso kukulitsa moyo wa zomangira ndi mbiya.

Maphunziro Oyendetsa

Ogwira ntchito ophunzitsidwa bwino amapanga kusiyana kwakukulu pakudalirika kwa zida. Maphunziro akuyenera kuyambika pamalo opanga ndikupitilira pakukhazikitsa ndikuyambitsa. Kubwerezabwereza pafupipafupi panthawi yowunikira kumathandiza kulimbikitsa machitidwe abwino. Othandizira amaphunzirakuzindikira zizindikiro zochenjeza mwamsanga, monga phokoso lachilendo kapena kuchepa kwachangu. Maphunziro amaphatikiza njira zoyenera zoyambira ndi zotsekera, njira zoyeretsera, komanso kufunikira koyendera nthawi zonse. Kutsindika kuwongolera ndi kuyang'ana nthawi kumathandiza kupewa kupsinjika kwamakina ndi kuvala msanga. Magulu omwe amaika ndalama pamaphunziro opitilira amawona zolephera zochepa komanso moyo wautali wa zida.

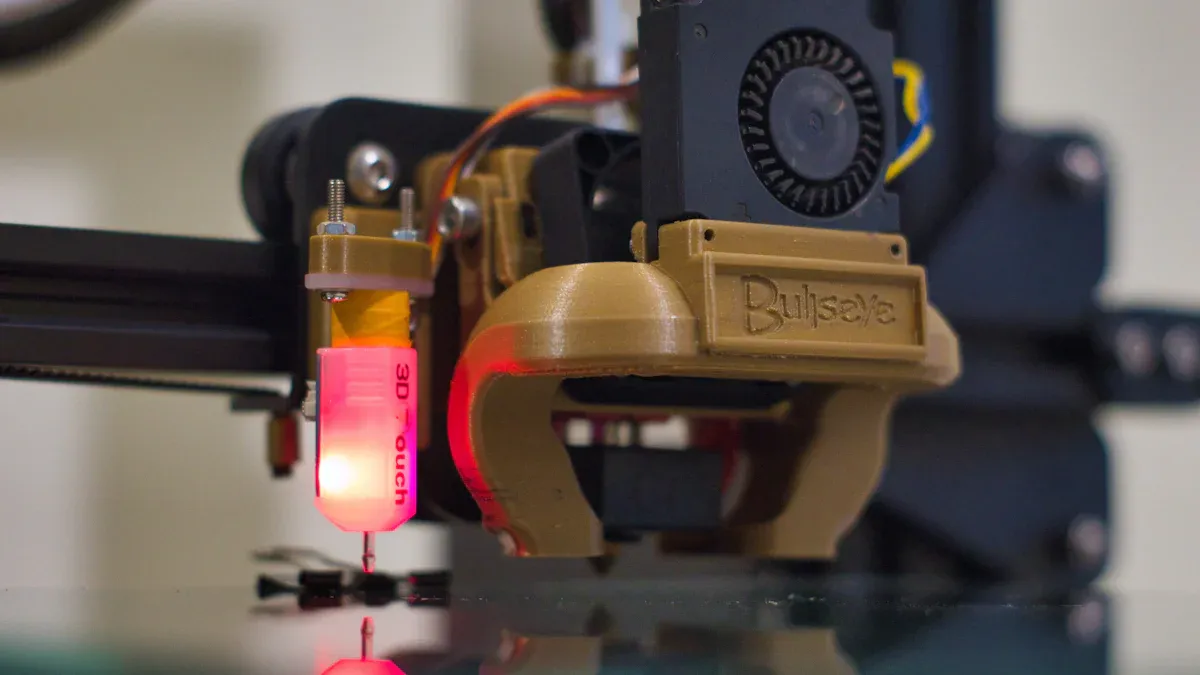

Professional Extruder Alloy Screw Barrel

Ubwino wa Alloy Screw Barrels

A akatswiri extruder aloyi wononga mbiyaimapereka maubwino angapo pamitundu yokhazikika. core ntchitomkulu-mphamvu aloyi chitsulo, pamene wosanjikiza wakunja amakhala ndi bimetallic composite. Mapangidwe awa amathandizira kukhazikika komanso kukana kuvala. Chosanjikiza chakunja, chomwe nthawi zambiri chimapangidwa ndi tungsten carbide kapena chitsulo chothamanga kwambiri, chimateteza ku abrasion ndi dzimbiri. Othandizira amawona moyo wautali wautumiki komanso kutsika kochepa.

| Mbali | Base Model | Zapamwamba Model | Pro Model |

|---|---|---|---|

| Kuwonjezeka kwa Mphamvu | Standard Aloyi | + 15% Mphamvu | + 30% Mphamvu |

| Kukaniza kwa Corrosion | Basic Coating | Chophimba Chowonjezera | Kupaka kwa Premium |

| Zokonda Zokonda | Zochepa | Wapakati | Zambiri |

Katswiri wa extruder alloy screw mbiya imalolanso makonda ambiri. kusinthasintha Izi amathandiza zosiyanasiyana processing zosowa ndi zipangizo.

Ma Applications mu Challenging Processing Environments

Mafakitole amagwiritsa ntchito migolo yaukadaulo ya extruder alloy screw m'malo ovuta. Migolo iyi imagwira zodzaza ndi abrasive monga ulusi wagalasi ndi mapulasitiki owononga monga ma fluorocarbons. Zomangamanga za bimetallic, zokhala ndi ma carbides ophatikizidwa mu nickel kapena chromium matrices, zimatsutsana ndi kuvala komanso kuwononga mankhwala. Oyendetsa amatha kuyendetsa makina pa liwiro lapamwamba komanso kupanikizika popanda kutenthedwa. Migoloyo imasunga zotsekera zolimba, zomwe zimapangitsa kuti zinthu zikhale zabwino kwambiri. Mafakitale ambiri, kuphatikiza mapulasitiki, mankhwala, ndi kukonza zakudya, amadalira migolo imeneyi kuti ikhale yolimba komanso yogwira ntchito.

Kukonza ndi Kukonza Migolo ya Alloy Screw

Kusamalidwa koyenera kumawonjezera moyo wa katswiri wa extruderalloy screw mbiya. Ogwira ntchito ayenera kusankha zipangizo zosagwira ntchito ndikugwiritsa ntchito mankhwala apamwamba monga nitriding kapena chrome plating. Kuyeretsa nthawi zonse ndi mankhwala oyeretsera malonda kumachotsa zotsalira ndikuletsa kumanga. Kuyang'ana miyezi isanu ndi umodzi iliyonse kuti mupeze ma resin olimbikitsidwa komanso chaka chilichonse kuti mupeze ma resins osadzazidwa kumathandiza kuzindikira kutha msanga. Pakafunika, njira zokonzanso zimaphatikizapo kuyambiranso, kuyikanso ndi wosanjikiza watsopano wa aloyi, kapena kusintha magawo owonongeka ndi ma liner. Kukonza zodzitetezera, monga kuthira mafuta ndi kukhathamiritsa njira, kumachepetsa zofunika kukonza ndikukulitsa moyo wautumiki.

Kuwunika pafupipafupi komanso kuthetsa mavuto mwachangu kumapangitsa kuti migolo ya extruder iyende bwino. Othandizira omwe amayeretsa, kuyang'ana, ndi kuthira mafuta zida amalepheretsa kutha kwa nthawi ndikuwonjezera moyo wautumiki. Kutayikira kwa zinthu, kutsika kwazinthu, kapena phokoso losazolowereka, akatswiri amisiri ayenera kuyang'ana mbiya yaukadaulo ya extruder alloy screw kuti abwezeretse magwiridwe antchito apamwamba.

FAQ

Ndi zizindikiro ziti zomwe zikuwonetsa kuti mbiya ya extruder screw ikufunika kukonzedwa?

Ogwiritsa ntchito amatha kuwona kutulutsa kwachepa, kumva phokoso lachilendo, kapena kuwona kusagwirizana kwazinthu. Kufufuza pafupipafupi kumathandiza kuzindikira zovuta izi msanga.

Kodi opareshoni ayenera kuyeretsa mbiya ya screw?

Mafakitole ambiri amalangiza kuyeretsa pambuyo pa kusintha kulikonse. Kwa nthawi yayitali, ogwira ntchito ayenera kuyeretsa kamodzi pa sabata.

Chifukwa chiyani musankhe mbiya ya alloy screw pazinthu zolimba?

Migolo ya alloy screw imalepheretsa kuwonongeka ndi dzimbiri. Amakhala nthawi yayitali akamakonza mapulasitiki owononga kapena owononga.

Mafakitale ambiri amadalira iwo kuti azigwira bwino ntchito.

Nthawi yotumiza: Aug-05-2025