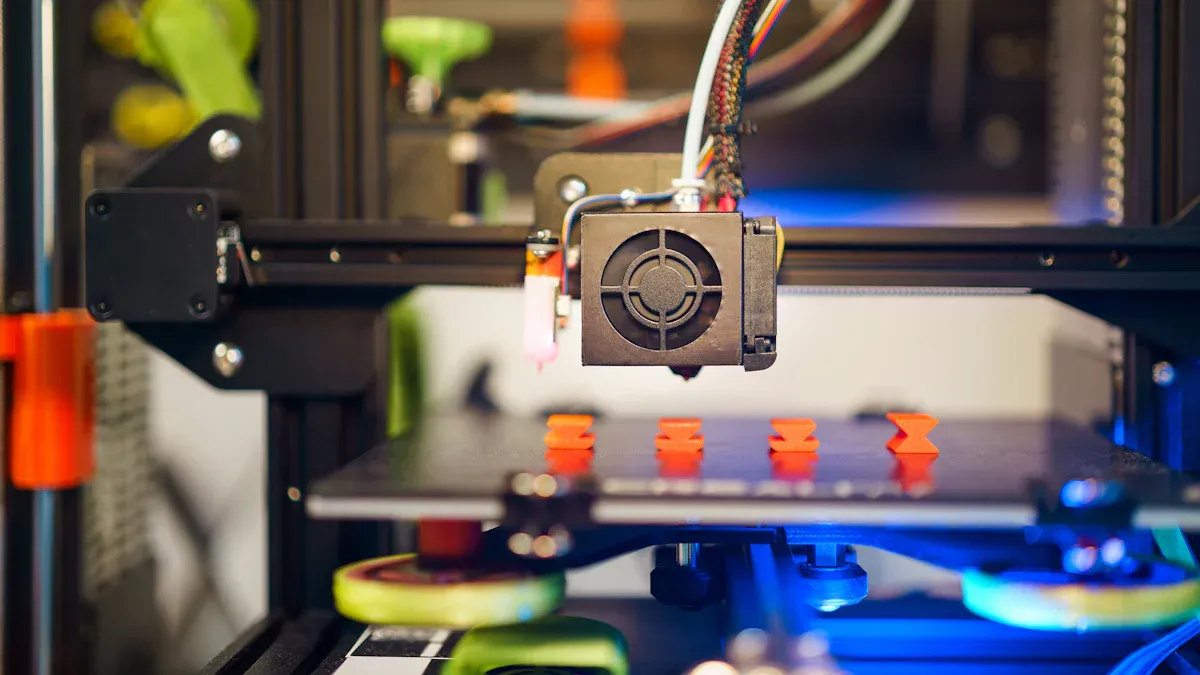

Kusunga bwino mu ma twin-screw extruder ndikofunikira kuti apange bwino. Kupuma ndi kuvala kumatha kukweza mtengo kwambiri ndikusokoneza kayendedwe ka ntchito. Kugwiritsa ntchito njira zomwe zatsimikiziridwa kumawonjezera magwiridwe antchito ndikuchepetsa zolepheretsa ntchito. Opanga akuyenera kuyika patsogolo njira zomwe zimayang'ana kwambiri migolo yolimba ya twin-screw extruder, migolo iwiri yofananira, ndiconical twin screw extruder migolo, pamodzi ndi zinthu wokometsedwa processing kwa pulasitiki extruder migolo limodzi wononga.

Zomwe Zimayambitsa Kuvalira mu Migolo Yokhazikika Yawiri-Screw Extruder

Mapangidwe Azinthu

Zomwe zimapangidwa ndi mapasa-screw extruder migolo zimagwira ntchito yofunika kwambiri pakukhalitsa kwawo komanso magwiridwe antchito. Kusankha zipangizo zoyenera kungachepetse kwambiri kuvala ndikuwonjezera moyo wa zigawozi. Zomwe zimayambitsa kuvala zokhudzana ndi kapangidwe kazinthu ndi izi:

| Chifukwa Chovala | Kufotokozera |

|---|---|

| Kusankha zinthu molakwika | Kusakwanira kogwira ntchito kwa screw ndi mbiya kumachepetsa moyo wawo. |

| Kusakwanira kutentha mankhwala kuuma | Kuuma kochepa kumathandizira kuvala pamalo ogwirira ntchito. |

| Otsika makina olondola | Kusawongoka bwino ndi kukhazikitsa kungayambitse kukangana ndi kuvala mwachangu. |

| Kukhalapo kwa fillers mu zinthu extruded | Zodzaza ngati calcium carbonate kapena ulusi wagalasi zimakulitsa kuvala. |

Zinthu zophatikizika m'migolo zimathandizanso kukana abrasion ndi dzimbiri. Mwachitsanzo, Ni60 imawonetsa kukana kowoneka bwino motsutsana ndi mavalidwe abrasive, kuchepetsa mitengo yovala komanso ndalama zogwirira ntchito. Alloy iyi imasunga umphumphu wamakina pa kutentha kokwera, kuonetsetsa kuti ndondomekoyi ikhale yokhazikika.

Processing Conditions

Processing zinthuzimakhudza kwambiri kuvala kwa migolo yolimba ya twin-screw extruder. Zinthu monga kutentha, kupanikizika, ndi mtundu wa zipangizo zomwe zikugwiritsidwa ntchito zimatha kufulumizitsa kuvala. Zinthu zazikuluzikulu zomwe zimathandizira kuti zivale zikuphatikizapo:

| Factor | Kufotokozera |

|---|---|

| Zida Zowonongeka | Kukonza zinthu zodzaza kwambiri, monga mapulasitiki odzazidwa ndi galasi kapena mamineral powders, kumatha kufulumizitsa kuvala pazomangira zonse ndi migolo. |

| Kutentha Kwambiri ndi Kupanikizika | Kutentha kwambiri kwa nthawi yayitali kapena kupanikizika kwambiri kumatha kufooketsa mbiya pamwamba, zomwe zimapangitsa kukokoloka. |

| Chemical Attack | Ma polima ena kapena zowonjezera zimatha kukhudzidwa ndi mbiya, kuchititsa dzimbiri kapena kubowola pakapita nthawi. |

| Kusasamalira bwino | Kuwunika kosawerengeka komanso kuchedwa kukonzanso kumapangitsa kuti zovala zazing'ono zisinthe ndikuwonongeka kwakukulu. |

Kusinthasintha kwa kutentha ndi kupanikizika panthawi yogwira ntchito kungathenso kukhudza kwambiri moyo wa migolo iwiri ya screw extruder. Kutentha kwapamwamba kogwira ntchito, komwe kumakhala kopitilira 200 ° C, kuphatikiziridwa ndi kuthamanga kwambiri, kumathandizira kuti mbiya ndi zowononga ziwonongeke. Zotsatira za abrasive za kusungunula ndi kupanikizika kwa makina panthawi yogwira ntchito kumawonjezera nkhaniyi, zomwe zimapangitsa kuti zinthu ziwonongeke komanso kulephera.

Mechanical Stress Factors

Kupsinjika kwamakina ndi chinthu china chofunikira chomwe chimapangitsa kulephera msanga kwa migolo yamapasa yamapasa. Zovutazi zimatha kuchitika kuchokera kuzinthu zosiyanasiyana zogwirira ntchito, kuphatikiza:

- Abrasive kuvala chifukwa zolimba particles mu polima eroding screw ndi mbiya pamwamba.

- Kutentha kotentha kumabwera chifukwa cha kutentha kwambiri komanso kutentha kosiyana kwa silinda.

- Kutopa kumabwera chifukwa cha kupsinjika mobwerezabwereza ndi kupanikizika, kufooketsa zomangira pakapita nthawi.

Kutsegula kwa cyclic kungathandizenso kutopa komanso kuvala pawiri-screw extruder mbiya.Kupanikizika kwa Torsional ndi kupindikaimatha kuyambitsa ndi kufalitsa ming'alu, pomwe ma depositi owopsa a carbide amatsogolera ku ming'alu yaying'ono pamtunda wa shaft. Zowonongeka monga mabowo ndi matope zimapangitsa kuti ming'alu ikule mofulumira komanso kulephera.

Kumvetsetsa zomwe zimayambitsa kuvala kwa migolo yolimba ya twin-screw extruder kumapangitsa opanga kugwiritsa ntchito njira zogwirira ntchito zokonzekera ndi kukhathamiritsa, ndikupititsa patsogolo kupanga bwino.

Zizindikiro za Wear to Monitor mu Twin-Screw Extruder Barrels

Kuwonongeka kwa Magwiridwe

Ogwira ntchito ayenera kuyang'anitsitsa kuwonongeka kwa magwiridwe antchito mu ma twin-screw extruder. Zizindikiro zoyamba ndi:

- Kuwonjezeka kwa chilolezo cha ndege chifukwa cha kuvala pa nsonga za ndege.

- Kufunika kowonjezera liwiro la screw kuti mukhalebe ndi kuchuluka kwanthawi zonse.

- Kutentha kwapamwamba kotuluka chifukwa cha kuchepa kwa kutentha kwapakati.

Kuwonongeka kwa magwiridwe antchito kumatha kukhudza kwambiri mtundu wazinthu. Mwachitsanzo, kusiyanasiyana kwa kutentha kungalepheretse kuwonongeka kwa zinthu zomwe sizimva kutentha, kuonetsetsa kuti yunifolomu imasungunuka. Ubale pakati pa screw speed ndi torque umakhudzanso kukameta ubweya komwe kumagwiritsidwa ntchito pokonza. Kuthamanga kwapamwamba kumatha kusintha kusakaniza koma kungayambitse kutentha kwambiri.

| Factor | Impact pa Product Quality |

|---|---|

| Kutentha | Imalepheretsa kuwonongeka kwa zinthu zomwe sizimva kutentha ndikuwonetsetsa kusungunuka kofanana. |

| Screw Speed ndi Torque | Zimakhudza kukameta ubweya; Kuthamanga kwapamwamba kumawonjezera kusakaniza koma kungayambitse kutenthedwa. |

| Kugwiritsa Ntchito Degassing | Amachotsa mipweya yotsekeredwa, kuteteza zolakwika ndikuwonetsetsa kusasinthika kwazinthu ndi mphamvu. |

Zizindikiro Zoyendera Zowoneka

Kuyang'ana kowoneka ndikofunikira kuti muzindikire kuvala kwa migolo yapawiri-screw extruder. Othandizira ayenera kuyang'ana:

- Surface Delamination: Zigawo zofooka zimatha kuwoneka ngati zosenda kapena kuphulika.

- Kusintha mtundu: Mizere yamitundu kapena zigamba zachilendo zimatha kuwonetsa kuchepetsedwa mphamvu.

- Splay Marks: Mikwingwirima yasiliva kapena yamtambo imasonyeza kuti mbali zake ndi zosalimba komanso kusagwira bwino ntchito.

Kuyang'ana zizindikiro zoonekeratu zakuwonongeka kwapamtunda, monga ma grooves akuya pa screw elements, ndikofunikira. Oyendetsa ayang'anenso ngati makina awonongeka kwambiri m'kati mwa mbiyayo ndikuyang'ana ming'alu ya nsonga ya shaft.

Kuyeza kwa Kulekerera

Miyezo yokhazikika imathandizira kuwunika momwe migolo ya twin-screw extruder ilili. Njira zovomerezeka ndi izi:

- Kuyeretsa mozama mbiya ya extruder ndi zinthu zotsuka.

- Pogwiritsa ntchito dial bore gauge ndi micrometer kuti muyese mainchesi awiri kapena atatu pansi pa mbiya.

- Kuyang'ana dzenje la chakudya m'dera la ming'alu, mawanga ochapira, mapindika, ndi zolakwika zina.

Oyendetsa ayenera kuyeza utali wonse pogwiritsa ntchito tepi muyeso kuyambira kumapeto kwa matako mpaka kumapeto kwa mphuno. Ayeneranso kuyeza kutalika kwa shank ndi kutalika kwake. Kugwiritsa ntchito zida monga dial calipers ndi micrometers kumatsimikizira kuwunika kolondola kwa kavalidwe.

- Tepi Mezani

- Seti ya Calipers

- Imbani Caliper

- 0-7 ″ ma Micrometer

- .500″ yokhuthala yofanana

- 25' Mulingo wa Tepi

Mayankho Othandiza Ochepetsera Nthawi Yopuma mu Migolo ya Twin-Screw Extruder

Kuti apititse patsogolo mphamvu ya ma twin-screw extruder, opanga ayenera kugwiritsa ntchito njira zochepetsera kuchepetsa nthawi. Zothetsera izi zikuphatikiza njira zosankhira zinthu, mikhalidwe yokonzedwa bwino, ndi njira zodzitetezera.

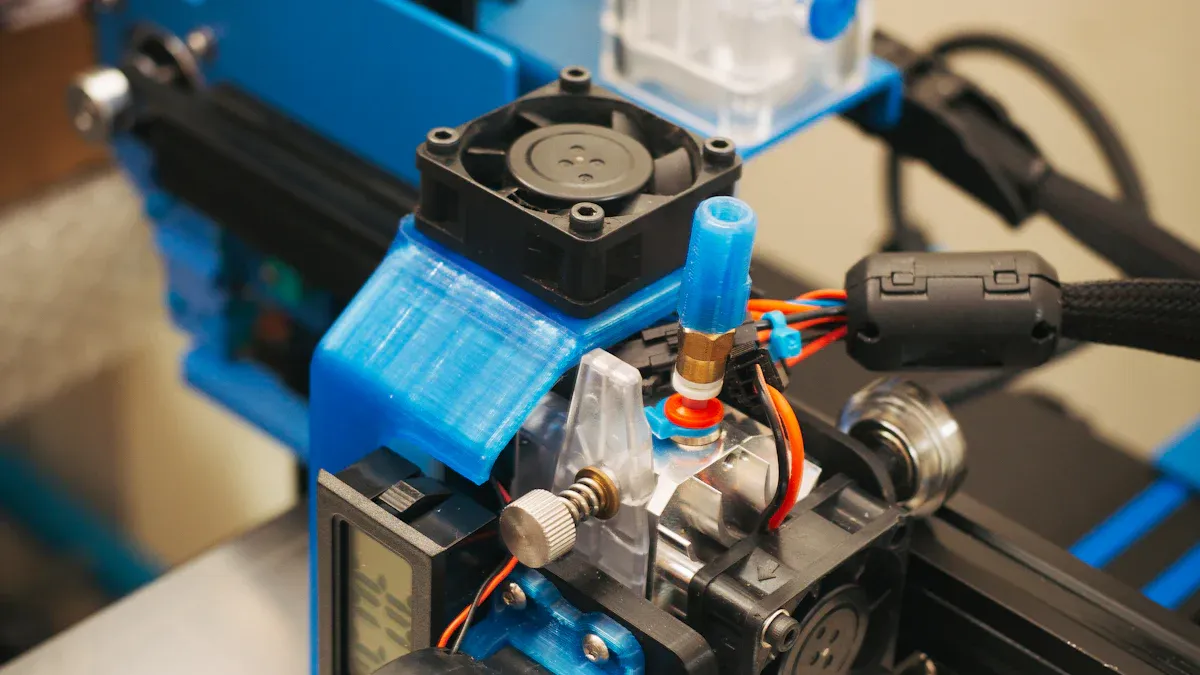

Njira Zosankhira Zinthu

Kusankha zipangizo zoyenerachifukwa mapasa-screw extruder migolo ndi yofunika kuti moyo wautali ndi ntchito. Tebulo ili likuwonetsa mitundu yosiyanasiyana ya zinthu ndi mapindu ake:

| Mtundu Wazinthu | Ubwino waukulu |

|---|---|

| Chitsulo cha carbon | Basic durability |

| Chitsulo chosapanga dzimbiri | Zabwino kukana dzimbiri |

| Chitsulo chachitsulo | Kupititsa patsogolo makina |

| Ufa zitsulo zitsulo | Kuvala kwapamwamba komanso kukana dzimbiri, kapangidwe kake kake, mphamvu zamakina apamwamba, moyo wautali wautumiki |

Kugwiritsa ntchito zokutira zapamwamba kapena chithandizo chapamwamba kumatha kupititsa patsogolo kukana kuvala. Mwachitsanzo, chithandizo cha nitriding chimatha kuwonjezera moyo wautumiki wa zomangira kawiri kapena katatu. Kuphatikiza apo, plating ya chromium ndi molybdenum imathandizira kulimba komanso kukana kufooka, ndikuwongolera magwiridwe antchito a mbiya.

Mkhalidwe Wokonzekera Wokometsedwa

Kukhazikitsa malo oyenera ogwirira ntchito ndikofunikira kuti zinthu zisamayende bwino. Kukhazikitsa njira zoyendetsera ntchito kumatha kuwongolera magawo azinthu bwino. Zotsatira zotsatirazi zitha kukulitsa mikhalidwe yopangira:

- Control Kutentha ndi Pressure: Sungani kutentha kosasunthika ndi kukakamizidwa kuti muteteze kutentha kwa kutentha ndikuonetsetsa kuti zinthu zikuyenda bwino.

- Yang'anirani Kapangidwe Kazinthu: Yang'anani nthawi zonse kapangidwe kazinthu zomwe zikukonzedwa kuti mupewe kuvala kwa abrasive kuchokera ku fillers.

- Sinthani Liwiro la Screw: Konzani liwiro la screw kuti muzitha kusakaniza bwino komanso kutulutsa kutentha, kupewa kutenthedwa.

Potengera izi, opanga amatha kuchepetsa kwambiri kuvala pamigolo yolimba ya twin-screw extruder ndikuthandizira kupanga bwino.

Njira Zopewera Kusamalira

Kukonzekera kokhazikika ndikofunikira kuti muchepetse nthawi yosakonzekera. Gome lotsatirali likuwunikiranjira zodzitetezera zogwira mtima:

| Yesetsani | Kufotokozera |

|---|---|

| Madongosolo Okonza Nthawi Zonse | Kusamalira pafupipafupi kumapangitsa kuti makina aziyenda bwino ndikupewa kuwonongeka kosayembekezereka. |

| Maphunziro Oyendetsa | Ogwiritsa ntchito ophunzira amatha kuzindikira zizindikiro zoyamba za kutha ndikuthana ndi zovuta zazing'ono zisanachuluke. |

| Spare Parts Inventory | Kusunga mndandanda wazinthu zofunikira kumatsimikizira kukonza mwachangu ndikuchepetsa nthawi yopuma. |

| Zida Zapamwamba | Zopangidwa kuchokera kuzinthu zolimba zimakulitsa magwiridwe antchito ndikuchepetsa zofunikira zosamalira. |

| Mafuta Oyenera | Mafuta opangira mafuta apamwamba kwambiri amachepetsa kukangana, amakulitsa moyo wamagulu ena, komanso amawongolera magwiridwe antchito. |

| Kuyendera Nthawi Zonse | Kuwona ngati zatha komanso kung'ambika kungalepheretse kukonza ndi kutsika kwamtengo wapatali, kusunga khalidwe lachinthu losasinthika. |

Kuyang'ana kosamalira kuyenera kuchitika pafupipafupi kuti muwongolere nthawi yayitali yogwirira ntchito ya migolo ya twin-screw extruder. Mwachitsanzo, kusintha mafuta ndi mafuta opaka maola 4000 aliwonse ndikuwunika kuvala kotala kumatha kupewa zovuta zazikulu.

Pogwiritsa ntchito mayankho ogwira mtimawa, opanga amatha kuchepetsa nthawi yopumira ndikuwonjezera magwiridwe antchito awo amapasa-screw extruder.

Opanga amatha kuchepetsa kwambiri nthawi yopuma komanso kuvala pogwiritsa ntchito njira zosamalira bwino. Kuyang'anitsitsa nthawi zonse, kuyang'ana mafuta, ndi kukonzanso panthawi yake kumatsimikizira ntchito yabwino.Kukhazikitsa mgwirizano wamphamvu wa othandizirakumawonjezera mwayi wopeza zida zapamwamba komanso thandizo la akatswiri. Kugwirizana kumeneku kumathandizira mayankho osinthika ogwirizana ndi zosowa zapadera, zomwe zimapangitsa kuti ntchitoyo ikhale yogwira mtima komanso yogwira ntchito bwino.

Zochita Zofunikira Zosamalira:

- Kuyang'ana kowoneka tsiku ndi tsiku ndi kuwunika kwamafuta

- Kuyendera pamwezi ndi mbiya

- Kukonzanso kwapachaka kwadongosolo lonse

Poika patsogolo machitidwewa, opanga amatha kupeza bwino ntchito kwanthawi yayitali.

FAQ

Kodi choyambitsa chachikulu chovala migolo ya twin-screw extruder ndi chiyani?

Choyambitsa chachikulu cha kuvala chimachokera ku kapangidwe kazinthu, momwe zinthu zimapangidwira, komanso kupsinjika kwamakina panthawi yogwira ntchito.

Ndikangati ndikayang'ane migolo yamapasa-screw extruder?

Yang'anani migolo yawiri-screw extruder pafupipafupi, mwezi uliwonse, kuti muzindikire kuti yatha komanso kupewa kukonza kodula.

Ndi zida ziti zomwe zili zabwino kwambiri pamigolo yawiri-screw extruder?

Chitsulo cha aloyi ndi zitsulo za ufa zimapereka kukana kwapamwamba komanso kulimba, kupititsa patsogolo moyo wa migolo yamapasa-screw extruder.

Nthawi yotumiza: Sep-05-2025