Ndikuwona momweSingle Screw Barrelskusintha pulasitiki yobwezeretsanso. Ndikagwiritsa ntchito mbiya ya Single screw pobwezeretsanso granulation, ndimawona kusungunuka kwabwinoko, kusakanikirana kosasunthika, komanso kucheperachepera. MaiPulasitiki Extruder Kwa Pulasitiki Yobwezeretsansoikuyenda bwino. Ndi kutentha kwenikweni ndi wononga liwiro, wangaExtruder Kwa Pulasitiki Yobwezeretsansoimakwaniritsa zotulutsa zapamwamba komanso mtundu wa pellet.

- Kusungunuka kwachangu

- Liwiro la screw

- Kutentha kwa mbiya

- Kumeta ubweya wa nkhawa

Njira Zofunikira Kuyendetsa Mwachangu

Kupititsa patsogolo Kusungunuka kwa Homogenization

Ndikagwiritsa ntchito chowonjezera changa chobwezeretsanso, ndimayang'ana kwambiri kusungunuka kofanana. Sungunulani homogenization imatanthauza kusakaniza pulasitiki bwinobwino pamene imasungunuka, kotero kuti pellet iliyonse imakhala ndi khalidwe lomwelo. Ndaphunzira zimenezokulamulira kutentha kwasungunuka ndi kutulukandizofunikira. Kafukufuku wa mapulasitiki ngati nayiloni ndi polypropylene akuwonetsa kuti ndikasunga yunifolomu yosungunuka, ndimapeza ma pellets opangidwanso bwino. Ngati kusungunuka sikufanana, pulasitiki yobwezerezedwanso imatha kukhala yofooka kapena yolimba.

Ndikuwona kusiyana kwamtundu wa pellet ndikamagwiritsa ntchito mbiya imodzi yopangira kusakaniza bwino. Mwachitsanzo, kafukufuku wa melt-state shear homogenization akuwonetsa kuti kusanganikirana kwameta ubweya wambiri mu mbiya imodzi zomangira kumakulitsa kufanana kwakuthupi ndi kutentha kwa mapulasitiki obwezerezedwanso. Izi zimachepetsa zowononga ndikusintha mawonekedwe a polima m'njira yomwe imathandizira njira zina zobwezeretsanso. Ndikuwona kuti ma pellets anga obwezerezedwanso ali ndi zolakwika zochepa komanso magwiridwe antchito abwino pamene kusungunuka kuli kofanana.

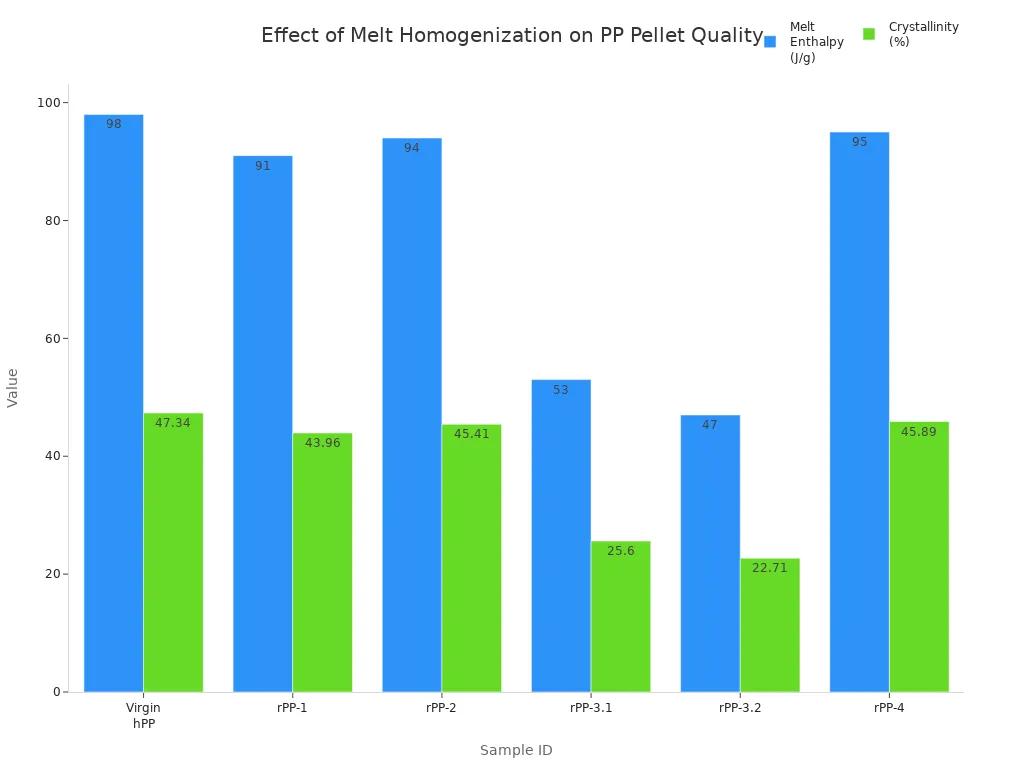

Manambala amatsimikizira zomwe ndikuwona m'sitolo yanga. Ndikayerekeza zitsanzo zobwezerezedwanso za polypropylene, zomwe zili ndi crystallinity yapamwamba komanso kusungunula enthalpy zimawoneka ndikuchita ngati pulasitiki ya namwali. Nali tebulo lomwe likuwonetsa momwe mikhalidwe yosinthira imakhudzira mtundu wa pellet:

| Chitsanzo cha ID | Sungunulani Enthalpy (J/g) | Crystallinity (%) |

|---|---|---|

| Virgin homopolymer PP (hPP) | 98 | 47.34 |

| Zobwezerezedwanso PP-1 (rPP-1) | 91 | 43.96 |

| Zobwezerezedwanso PP-2 (rPP-2) | 94 | 45.41 |

| Zobwezerezedwanso PP-3.1 (rPP-3.1) | 53 | 25.60 |

| Zobwezerezedwanso PP-3.2 (rPP-3.2) | 47 | 22.71 |

| Zobwezerezedwanso PP-4 (rPP-4) | 95 | 45.89 |

Nthawi zonse ndimayang'ana zotsatira monga rPP-1, rPP-2, ndi rPP-4, zomwe zili pafupi ndi namwali PP. Makhalidwe otsika, monga rPP-3.1 ndi rPP-3.2, andiuze kuti kusungunuka sikunasakanizidwe bwino kapena kuipitsidwa.

Ndikawongolera kusungunuka kwamadzi ndi kusakanikirana, ndimawonanso zinthu zabwino zamakina pazomaliza. Ma pellets anga obwezerezedwanso amatambasula ndikunyamula pafupifupi pulasitiki yatsopano, zomwe zikutanthauza kuti nditha kuzigwiritsa ntchito pazofunikira kwambiri.

Optimized Screw Geometry

Maonekedwe ndi kapangidwe ka wononga mkati mwa extruder yanga imapanga kusiyana kwakukulu. Ndayesa ma screw geometries osiyanasiyana ndikuwona momwe amakhudzira kugwiritsa ntchito mphamvu, kusungunuka kwabwino, ndi zotuluka. Ndikagwiritsa ntchito screw yokhala ndi geometry yolondola, ndimapeza kusakanikirana kosasintha komanso kutulutsa kwapamwamba. Ndimagwiritsanso ntchito mphamvu zochepa, zomwe zimapulumutsa ndalama komanso zimachepetsa kuvala kwa zipangizo zanga.

- Screw geometry imakhudza kuchuluka kwa mphamvu zomwe ndimafunikira komanso momwe kutentha kwasungunuka kumakhala kokhazikika.

- Kuchulukitsa liwiro la screw kungachepetse kugwiritsa ntchito mphamvu, koma mapangidwe a screw ayenera kufanana ndi zinthuzo.

- Zotchingira zotchingira ndi zinthu zosakanikirana zimathandizira kuti kutentha kusungunuke kukhale kofanana komanso kusakanikirana bwino.

- Zopangira zina zomangira zimandilola kuyendetsa extruder mwachangu osataya mtundu.

- The screw geometry yolondola imalinganiza mphamvu zamagetsi ndikutulutsa kwambiri komanso kusungunuka kwabwino.

Ndawona kuti zomangira zotchinga, zomwe zimalekanitsa pulasitiki yolimba ndi yosungunuka, zimandilola kuthamanga kwambiri ndikupeza zotulutsa zambiri. Komabe, m'pofunika kuyang'anitsitsa kuchuluka kwa shuga m'magazi. Kusakaniza zinthu monga gawo la Maddock shear kumandipatsa homogenization yabwinoko, zomwe zikutanthauza kuti zolakwika zochepa pama pellets anga.

Nayi kufananitsa mwachangu kwa mitundu ya screw ndi zotsatira zake:

| Kujambula Geometry | Kusakaniza Kusakanikirana (Homogeneity) | Kupititsa patsogolo | Zolemba |

|---|---|---|---|

| Zotchinga Zotchinga | Zabwino pakuchita bwino, zimafunikira kuwongolera mosamala | Wapamwamba | Zabwino pamagulu akulu, yang'anani kusakanizikana kosagwirizana pa liwiro lalikulu kwambiri |

| Zopangira Zigawo Zitatu | Zokhazikika, koma zotsika kwambiri | Wapakati | Zabwino kupanga mosasunthika, zosasinthika |

| Zosakaniza Zosakaniza | Homogenization yabwino | Zimasiyana | Maddock shear amapereka kusakaniza bwino, makamaka kwa mapulasitiki olimba |

Nthawi zonse ndimasankha screw geometry yomwe imagwirizana ndi pulasitiki yomwe ndikubwezeretsanso. Mwanjira iyi, ndimapeza liwiro labwino kwambiri, mtundu, komanso kugwiritsa ntchito mphamvu.

Zida Zapamwamba za Migolo

Zomwe zimapangidwa ndi screw barrel zimangofanana ndi kapangidwe kake. Ndimadalira migolo yopangidwa kuchokera kuzitsulo zamtundu wapamwamba kwambiri monga 38CrMoAl, zomwe zimapereka mphamvu ndi kulimba. Ndikagwiritsa ntchito migolo yokhala ndi nitrided, ndimawona kulumpha kwakukulu pakuuma. Izi zikutanthauza kuti zida zanga zimatha nthawi yayitali, ngakhale ndikamakonza mapulasitiki owopsa kapena oipitsidwa.

- Zitsulo za alloy monga 38CrMoAlA ndi AISI 4140 zimandipatsa kulimba komwe ndimafunikira.

- Zitsulo zaufa zazitsulo zimaperekanso kuvala bwino komanso kukana dzimbiri.

- Chithandizo cha nitriding chimakulitsa kuuma kwa pamwamba, nthawi zambiri kufika pa HV900 kapena kupitilira apo.

- Zovala za bimetallic, monga tungsten carbide, zimateteza ku zodzaza ndi abrasive.

- Chromium plating imawonjezera chitetezo china ku dzimbiri ndi kuvala.

Ndaona kuti ndikamagwiritsa ntchito migolo yokhala ndi zinthu zapamwambazi komanso zokutira, ndimawononga nthawi komanso ndalama zochepa pokonza zinthu. Extruder yanga imayenda nthawi yayitali pakati pa nthawi yautumiki, ndipo sindiyenera kuda nkhawa kwambiri ndi kusokonekera. Kudalirika kumeneku kumandipangitsa kuyang'ana kwambiri kupanga ma pellets obwezerezedwanso apamwamba kwambiri.

Langizo:Nthawi zonse mufanane ndimbiya zakuthupiku mitundu ya mapulasitiki ndi zowonjezera zomwe mumakonza. Zipangizo zolimba ndi zokutira zimalipira mukamagwiritsa ntchito zinyalala zowononga kapena zosakanikirana zapulasitiki.

Pophatikiza kusungunula kwabwinoko, kukhathamiritsa kwa screw geometry, ndi zida zapamwamba za mbiya, ndimapeza bwino kwambiri komanso zotsatira zabwino pantchito yanga yobwezeretsanso pulasitiki. Njirazi zimagwirira ntchito limodzi kuti zipereke mtundu wokhazikika, zotulutsa zapamwamba, komanso zotsika mtengo.

Kuthetsa Mavuto Omwe Amagwiritsidwanso Ntchito Kubwezeretsanso

Kulimbana ndi Kuipitsidwa ndi Kusiyanasiyana kwa Feedstock

Ndikayendetsa ntchito yanga yobwezeretsanso, ndimakumana ndi chakudya chosayembekezereka tsiku lililonse. Magulu ena amakhala ndi pulasitiki yoyera, yofanana. Ena amafika atasakanizidwa ndi dothi, zitsulo, kapena chinyezi. Ndikudziwa kuti tinthu tating'onoting'ono ta regrind timakhala ndi kachulukidwe kakang'ono kwambiri kuposa ma pellets a virgin. Izi zimachepetsa kutulutsa ndikupangitsa kuti extruder yanga igwire ntchito molimbika. Ngati sindithetsa nkhaniyi, ndikuwona kutentha kwapamwamba kwambiri komanso kutsika kwa ma pellets.

Ndimadalira mbiya yanga ya screw kuti ndithane ndi zovuta izi. Ma geometry a feed zone, makamaka matumba okulirapo, amathandizira kudyetsa komanso kutumiza zolimba. Kapangidwe kameneka kamapangitsa kuti zinthu ziziyenda bwino komanso kuti ziziyenda bwino. Ndikuwona kuti extruder yanga imakhalabe yosungunuka ngakhale ndikakonza mapulasitiki osakanikirana kapena oipitsidwa.

Nazi zovuta zazikulu zomwe ndimakumana nazo pakubwezeretsanso pulasitiki:

- Mawonekedwe a regrind osakhazikika komanso kuchulukira kochepa kwambiri

- Kuchepetsa kugwiritsa ntchito komanso kuchita bwino

- Kutentha kwapamwamba kusungunula ndi mawindo opangira mawindo opapatiza

- Kuwonongeka ndi kuwonongeka kwa zinthu

- Kusintha kosinthika ndi mapulasitiki osakanikirana

mbiya yanga imodzi ya screw imandithandiza kuthana ndi mavutowa. Ndikuwona kudyetsedwa kwabwinoko, kuyenda kosasinthasintha kwa zinthu, komanso kugwiritsa ntchito mphamvu zochepa. Tekinoloje iyi imandilola kuti ndizitha kukonza mapulasitiki ambiri obwezerezedwanso popanda kupereka nsembe.

Nthawi zambiri ndimafanizitsa ma screw extruder ndi ma screw extruders. Makina opangira ma twin screws amapereka kusakaniza bwino komanso kuchotsera mpweya, koma amalimbana ndi kupsinjika kwakukulu komanso kuipitsidwa. Ma screw extruder amodzi, monga anga, amatha kusefera mozama kwambiri komanso amalekerera bwino zowononga. Nachi kufananitsa mwachangu:

| Mbali | Single Screw Extruder | Twin Screw Extruder |

|---|---|---|

| Kusakaniza Mwachangu | Kusakaniza kwapakatikati, homogenization yochepa | Kusakaniza kopambana, kuchitapo kanthu kogawa / kufalitsa |

| Kutentha Uniformity | Pakatikati, makonda otentha/ozizira | Kwambiri yunifolomu Sungunulani kutentha kugawa |

| Linanena bungwe Kukhazikika | Chabwino, akhoza kukhala ndi pulsation | Kutulutsa kokhazikika, kokhazikika |

| Zinthu Zosiyanasiyana | Zabwino kwambiri zofananira, zida za namwali | Imasamalira zowonjezera, zophatikizika, zowononga zopatsa thanzi |

| Degassing luso | Zochepa kapena ayi | Wapamwamba, wokhala ndi ma doko opanda vacuum ndi malo olowera |

| Mlandu Wabwino Wogwiritsa Ntchito | Yaing'ono, namwali woyera ABS | Industrial sikelo, zapaderazi, achikuda, zobwezerezedwanso ABS |

Ndimasankha mbiya zomangira zing'onozing'ono chifukwa cha kupanikizika kwambiri komanso kulolerana bwino ndi zonyansa. Chisankhochi chimandithandiza kupewa kukonza zodula komanso kuti chingwe changa chobwezeretsanso chiziyenda bwino.

Kuchepetsa Kuvala Kuchokera ku Zida Zowonongeka

Mapulasitiki abrasive ndi fillers, monga glass fibers, talc, ndi calcium carbonate, amapereka vuto lalikulu mu chomera changa. Zida izi zimawononga zomangira ndi migolo mwachangu. Ndinkakonda kusintha zigawo zambiri, zomwe zimawonjezera nthawi yopuma komanso ndalama.

Tsopano, ndimagwiritsa ntchito mbiya za screw imodzi yokhala ndi mankhwala apamwamba komanso zokutira. Mitsuko yanga imakhala ndi nitrided pamwamba ndi zigawo za bimetallic alloy. Zowonjezera izi zimakulitsa kuuma komanso kukana abrasion. Ndikuwona kusiyana kwakukulu pakukhazikika. Zipangizo zanga zimatha nthawi yayitali, ngakhale ndikamakonza mapulasitiki olimba, otupa.

Mapangidwe akuluakulu omwe amandithandiza kuchepetsa kuvala ndi awa:

- Wokometsedwa screw geometry kupewa kuthamanga spikes ndi kusungunula chipwirikiti

- Kusankhidwa kwa zinthu zosavala komanso zokutira zapadera

- Mapangidwe opangidwa ndi zida zapadera ndi zodzaza

- Makina olondola kuti athe kumaliza bwino

- Pulogalamu yoyeserera kuti mumvetsetse kugawa kwamakasitomala osungunuka

Ndinaphunzira kutikuvala kwakukulu kumachitika pafupi ndi gawo la kusintha, kumene zolimba mphero ndi kupsyinjika kukwera. Posankha zida zoyenera ndi zokutira, Ikuchepetsa kuvala mpaka 60%. Kuyang'ana nthawi zonse ndikukonza madera ovala kwambiri, monga malo odyetserako ndi kutulutsa, sungani ma extruder anga kukhala apamwamba.

Langizo:Nthawi zonse ndimafananiza kapangidwe kanga ka mbiya ndi mapulasitiki ndi zodzaza zomwe ndimapanga. Njirayi imakulitsa moyo wa zida ndikuthandizira kupanga bwino.

Kupititsa patsogolo Kukhazikika kwa Njira ndi Kusasinthika kwa Zotuluka

Kukonza kokhazikika ndikofunikira popanga ma pellets apamwamba kwambiri. Ndisanagwiritse ntchito ukadaulo umodzi wa screw barrel, ndidalimbana ndi kusefukira, kusasunthika, komanso kusayenda bwino kwa zinthu zolimba. Mavutowa adayambitsa kutsika kwamitengo, kuchulukirachulukira, komanso kukwera mtengo kwa ogwira ntchito.

Ndi mbiya yanga ya JT single screw, ndimapeza kusungunuka kokhazikika komanso kutulutsa kosasintha. Makina owongolera otsogola, kuphatikiza masensa ndi zowongolera zomveka, zimandithandiza kukhalabe ndi kutentha kokhazikika komanso kupanikizika. Ndimayang'anitsitsa zochitika za ndondomeko kuti ndipewe kusinthasintha komwe kungathe kusokoneza ntchitoyo.

Ndimagwiritsa ntchitoma aloyi a bimetallic ndi zokutira zapamwambakuonjezera kufooka ndi kuwonongeka. Zinthuzi ndizofunikira kwambiri pokonza mapulasitiki abrasive kapena recycled. Kukhazikika kwadongosolo kumalepheretsa kusiyanasiyana kwazinthu zamagulu ndikuchepetsa zinyalala.

Nazi njira zomwe ndimatenga kuti ndondomekoyi ikhale yokhazikika:

- Kusamalira nthawi zonse ndikusintha nthawi yake zomangira zomata ndi migolo

- Kuwunika kutentha ndi kupanikizika ndi machitidwe apamwamba olamulira

- Kugwiritsa ntchito makonda wononga mbiri yabwino kusungunula homogeneity ndi kusakaniza

- Kuyang'ana madera ovala kwambiri kuti muchepetse nthawi yosayembekezereka

Kafukufuku akuwonetsa kuti kukhathamiritsa liwiro la screw ndi madera otentha kumawonjezera kutulutsa komanso kumathandizira kubwezanso. Kuthamanga kocheperako kumawonjezera torque ndikuchepetsa mphamvu zamakina, zomwe zimapangitsa kuti zitheke bwino komanso kutulutsa kosasintha. Ndalemba kuchuluka kwa zotulutsa za 18% mpaka 36% nditatha kukonza mapangidwe anga a screw barrel.

Zindikirani:Kuyang'anira kosasintha ndi kukonza molosera kumatalikitsa moyo wa zida ndikuwongolera kukhazikika kwanga mu ntchito yanga yobwezeretsanso.

Pothana ndi kuipitsidwa, kuvala, ndi kukhazikika kwadongosolo, mbiya yanga imodzi yomangira imandithandiza kutulutsa ma pellets odalirika, apamwamba kwambiri. Ndimakwaniritsa zofunikira pakukonzanso kwamakono ndi chidaliro komanso kuchita bwino.

Single Screw Barrel for Recycling Granulation: Real-World Results

Kuchulukitsidwa kwa Ntchito ndi Ubwino

Nditasinthira ku mbiya imodzi yopangira nsonga zobwezeretsanso granulation, ndidawona kukwera koonekera bwino pakutulutsa komanso mtundu wa pellet. Ma pellets anga obwezerezedwanso tsopano akuwonetsa mphamvu zamakina bwino komanso kuwonekera bwino. Nditha kuwongolera kukula kwa pellet molondola, zomwe zimandithandiza kukwaniritsa zofunikira zamakasitomala. Kuwongolera kutentha kwapamwamba kumapangitsa kuti kusungunuka kusungunuke kukhale kosasunthika, kotero ndimakhala ndi zolakwika zochepa komanso ma pellets ambiri ofanana.

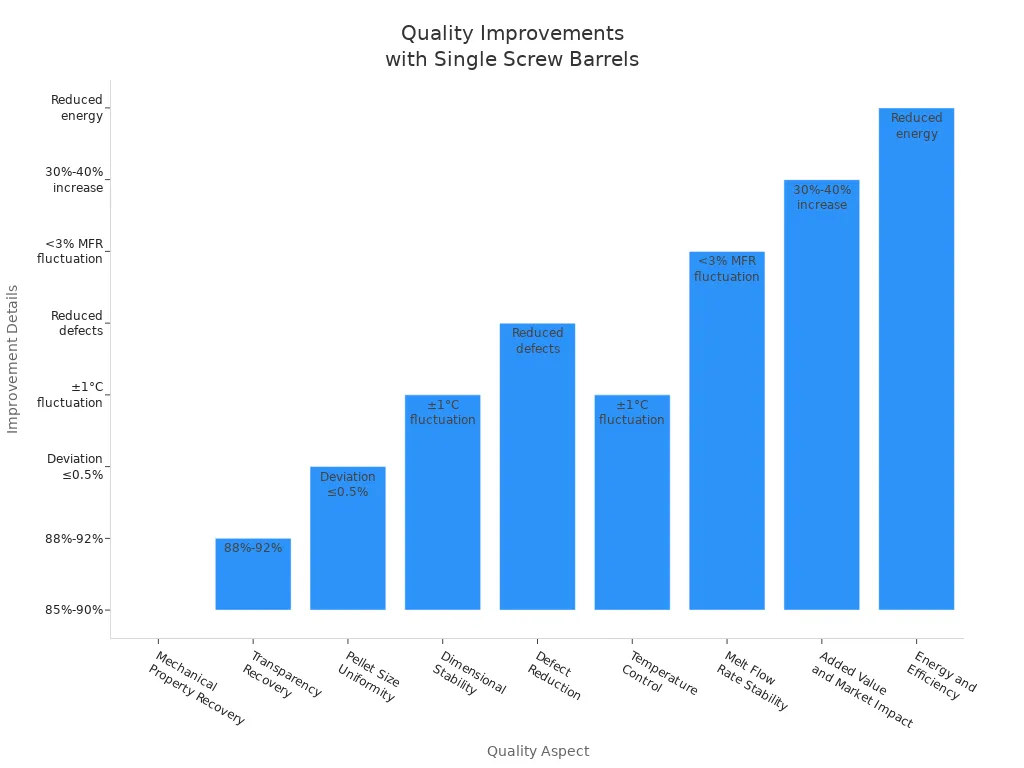

| Quality Mbali | Tsatanetsatane Wowonjezera |

|---|---|

| Kubwezeretsa Katundu Wamakina | 85% -90% kuchira mlingo, apamwamba kwambiri kuposa ndi zida wamba |

| Transparency Recovery | 88% -92% kuchira |

| Kukula kwa Pellet Uniformity | Kupatuka kwa kukula mkati mwa 0.5% |

| Dimensional Kukhazikika | Kutentha kofanana (± 1 ° C kusinthasintha) kumatsimikizira bata |

| Kuchepetsa Chilema | Zonyansa zochepa ndi zolakwika |

| Kuwongolera Kutentha | Kuwongolera kwa magawo asanu, kusinthasintha kwa ± 1 ° C |

| Kukhazikika kwa Melt Flow Rate | Kusinthasintha kwa MFR pansi pa 3% |

| Mtengo Wowonjezera ndi Kukhudza Kwamsika | 30-40% kuwonjezeka kwa mtengo wowonjezera |

| Mphamvu ndi Mwachangu | Kugwiritsa ntchito mphamvu pang'ono, kuchita bwino kwambiri |

Kusungirako Pansi ndi Nthawi Yopuma

Ndaphunzira kuti chisamaliro chanthawi zonse chimasunga mbiya yanga imodzi ya screw kuti yobwezeretsanso granulation ikuyenda bwino. Ndimatsatira ndondomeko yosamalira bwino ndipo ndimayendera mbiya mlungu uliwonse. Nthawi zonse ndimakhala ndi kutentha komanso kuthamanga kwa screw kuti ndipewe kupsinjika pamakina. Zakudya zapulasitiki zoyera, zosanjidwa bwino zimathandiza kupewa kuwonongeka kwa zinthu zowononga. Ndimatsuka ndi kuthira mafuta zinthu zomwe zikuyenda kuti zithetse dzimbiri komanso kugundana. Ndikaona zotha, ndimazisintha nthawi yomweyo. Ndimasankha migolo yopangidwa kuchokera kuzitsulo zolimba zokhala ndi zokutira zapadera, monga nitriding, kuti atalikitse moyo wawo.

- Kuyendera mbiya mlungu uliwonsesungani zida zanga pamalo apamwamba.

- Kutentha koyenera ndi kukakamiza kumalepheretsa kuvala.

- Zakudya zoyera zimachepetsa kuwonongeka kwamkati.

- Kuyeretsa pafupipafupi ndi kuthirira kumasiya kuwonongeka.

- Kusintha gawo lokhazikika kumapewa kutsika kosayembekezereka.

- Ma alloys olimba komanso zokutira zimapangitsa kuti mbiya ikhale yayitali.

Zomera zomwe zimatsata njirazi zimafotokoza nthawi yocheperako komanso ndalama zochepetsera kukonza. Mzere wanga wobwezeretsanso tsopano ukuyenda bwino komanso modalirika.

Nkhani Yophunzira: JT Single Screw Barrel mu Multi-Plastic Recycling

Ndinayika mbiya ya JT single screw kuti ibwezeretsenso granulation mu chomera changa kuti ndigwire mapulasitiki osiyanasiyana monga PE, PP, ndi PVC. Zida zosavala, monga38CrMoAl ndi tungsten carbide, atalikitsa moyo wa mbiya. Panopa ndimagwiritsa ntchito ndalama zochepa pokonza ndi kukonzanso zinthu zina. Mzere wanga wopanga suyima kawirikawiri, kotero ndimakwaniritsa nthawi yanga yobweretsera. Kagwiridwe kake ka mbiya ya JT single screw pobwezeretsanso granulation kwathandizira kutulutsa kwanga ndikuchepetsa mtengo wanga. Ndikuwona zododometsa zochepa komanso bwinokhalidwe la pellet, zomwe zimandithandiza kuti ndikhalebe wampikisano pamsika.

Ndikuwona momwe mbiya za screw imodzi zimathetsera zovuta zazikulu zobwezeretsanso. Zomwe ndakumana nazo zikuwonetsa kusungunuka kwabwinoko, kusakanikirana, komanso kukhazikika kwadongosolo. Ndi mbiya imodzi ya wononga yobwezeretsanso granulation, ndimakwaniritsa bwino kwambiri komanso kudalirika. Zosinthazi zimathandizira ntchito zoyeretsa, zotsika mtengo, ndikundithandiza kukwaniritsa zomwe makampani akufuna kuti akonzenso pulasitiki.

FAQ

Ndi mapulasitiki ati omwe ndingakonze ndi mbiya ya JT single screw?

Nditha kukonza mapulasitiki ambiri, kuphatikiza PE, PP, PS,Zithunzi za PVC, PET, PC, PA. Mgolowu umasinthasintha kuzinthu zosiyanasiyana kuti ubwezerenso bwino.

Kodi ndingachepetse bwanji kusweka pa screw barrel yanga?

Ndimagwiritsa ntchito migolo yopangidwa kuchokera kuzitsulo zolimba zokhala ndi zokutira za nitrided kapena bimetallic. Kuyeretsa nthawi zonse ndikusintha koyenera kumandithandiza kukulitsa moyo wa mbiya ndikusunga magwiridwe antchito apamwamba.

Chifukwa chiyani kusungunula homogenization ndikofunikira pakubwezeretsanso?

Sungunulani homogenization amandipatsa yunifolomu pellets. Ndikuwona zolakwika zochepa komanso kulimba kwazinthu zabwinoko. Kusakaniza kosasinthasintha kumandithandiza kukwaniritsa miyezo yabwino komanso zosowa za makasitomala.

Nthawi yotumiza: Aug-21-2025