Ma granulator ang'onoang'ono a PE mu 2025 amagwiritsa ntchito ma motors apamwamba kwambiri, kukhathamiritsa kwazinthu, komanso makina enieni anthawi yeniyeni kuti achepetse kugwiritsa ntchito mphamvu. Othandizira amawona zotsatira zaposachedwa, monga aKutsika kwa 40% pakugwiritsa ntchito mphamvu pa tonipoyerekeza ndi chikhalidwemakina omangira amodzi or wotuluka wononga wononga extrudermachitidwe. Kubwezeretsa kutentha kwa zinyalala kumathandizansomakina opanda madzi granulatorntchito.

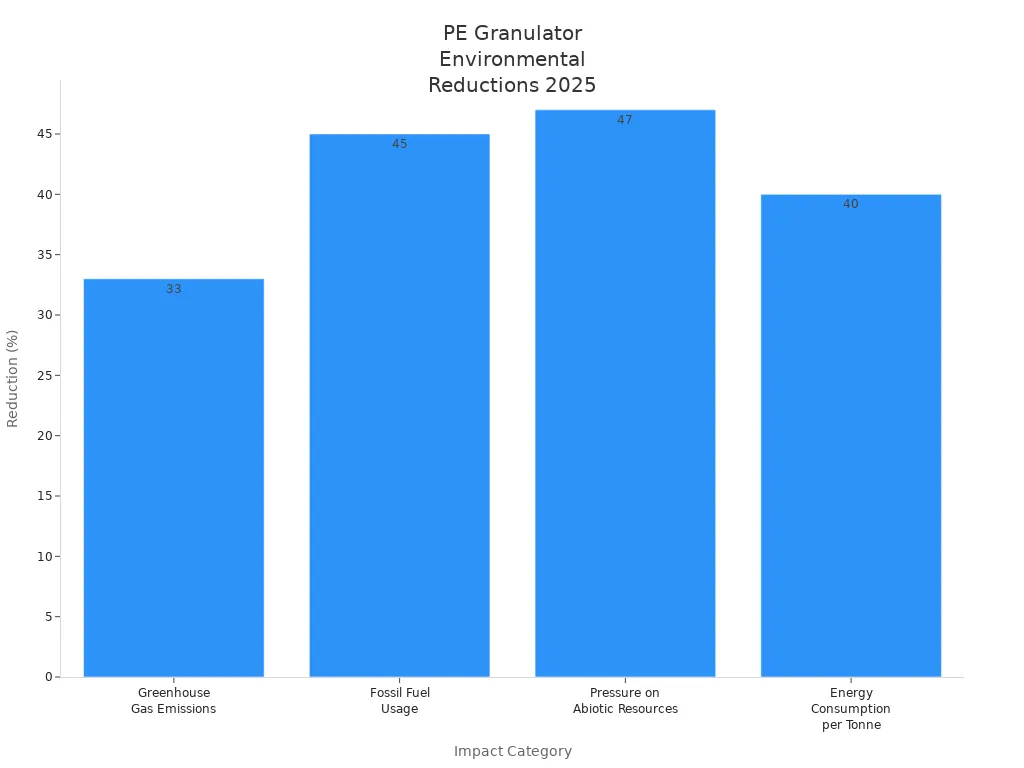

| Metric | Kuchepetsa Kukwaniritsidwa mu 2025 Poyerekeza ndi Zaka Zam'mbuyo |

|---|---|

| Kuchepetsa Kutulutsa Gasi Wowonjezera | 33% kuchepa |

| Kuchepetsa Kugwiritsa Ntchito Mafuta Otsalira | 45% kuchepa |

| Kupanikizika pa Abiotic Resources | 47% kuchepa |

| Kugwiritsa Ntchito Mphamvu pa Tonne | Otsika mpaka 10 kW-h/ton, 40% yocheperapo kuposa zida zachikhalidwe |

PE Small Environmental Granulators: Energy-Saving Technologies

Ma Motors Amphamvu Kwambiri ndi Zida Zotumizira

Ma granulator ang'onoang'ono a PE mu 2025 amadalirama motors apamwamba kwambiri komanso zida zotumizira zotsogolakuti tipeze ndalama zopulumutsa mphamvu. Ma motors awa amasintha mphamvu yamagetsi kukhala mphamvu yamakina osataya pang'ono, kuwonetsetsa kuti mphamvu zambiri zolowera zimayendetsa njira ya granulation. Zipangizo zopatsirana mwaukadaulo zimathandiziranso bwino izi pokulitsa momwe mphamvu zimayendera kuchokera pagalimoto kupita kuzinthu zodulira ndi zotulutsa. Akaphatikizidwa, matekinolojewa amachepetsa kugwiritsa ntchito mphamvu zonse panthawi yogwira ntchito. Kuphatikiza uku kumapanga njira yopulumutsira mphamvu yomwe imathandizira kugwiritsa ntchito mphamvu zochepa komanso kupanga bwino kwambiri. Opanga amapindula ndi mabilu amagetsi otsika komanso kuwongolera magwiridwe antchito a zida. Kugwiritsiridwa ntchito kwa ma motors apamwamba kwambiri ndi zipangizo zopatsirana kumatalikitsa moyo wa granulator, kuchepetsa zosowa zokonza ndi nthawi yopuma.

Langizo:Kukwezera ma motors okwera kwambiri komanso makina otumizira amatha kuchepetsa kugwiritsa ntchito mphamvu mpaka 30% poyerekeza ndi mitundu yakale.

Intelligent Automation ndi Process Optimization

Intelligent automation imayima pachimake cha ma granulator amakono a PE. Makinawa amagwiritsa ntchito maulamuliro anzeru kuti ayang'anire ndikusintha zizindikiro zazikulu zogwira ntchito monga kutentha, kuthamanga kwagalimoto, ndi kugwedezeka. Othandizira amatha kudalira zinthu monga PLC touch screens, zomwe zimalola kusintha kwamphamvu kwa kutentha ndi kukula kwa pellet. Zomverera zimazindikira zinthu monga kutsekeka kwa kufa kapena kulemetsa kwagalimoto, kuchepetsa chiwopsezo cha kutsika kosayembekezereka.

- Smart granulator imayang'anira mayendedwe amomwe amagwirira ntchito pokonzekera zolosera.

- Makina opangidwa ndi AI amadziwitsa kukonzekera kukonza, monga nthawi yosinthira mipeni kapena zonyamula mafuta.

- Mapulatifomu amtambo amathandizira kuyang'anira kutali ndikutumiza zikumbutso zosamalira.

- Wiring kabati yamagetsi imathandizira kuphatikiza kosavuta ndi zida zina.

- Zochita zokha zimachepetsa kulowererapo pamanja, kukonza chitetezo ndi kudalirika.

- Kukhathamiritsa kwa njira kumawongolera magawo ogwiritsira ntchito, kuwongolera granulation ndi kuchepetsa kuwononga mphamvu.

- Mapangidwe a modular amalola makonda azinthu zosiyanasiyana komanso zosowa zopanga.

Njira zokometsera ma process zimawonjezera mphamvu zamagetsi. Mapangidwe ophatikizika amamakina amaphatikiza shredding, kudula, extrusion, ndi pelletizing kukhala ntchito imodzi mosalekeza. Njira imeneyi imachepetsa ntchito, nthawi, ndi mphamvu. Njira zodyetsera zosasinthasintha zimakhazikika pakuyenda kwa zinthu, kulepheretsa kutsika komanso kuwongolera zotulutsa. Zinthu zodzichitira zokha monga zowongolera zodyetsera, zosefera zapawiri, ndikusintha liwiro la mpeni zimatsimikizira kupanga bwino komanso kothandiza. Ma mota osagwiritsa ntchito mphamvu, ma drive othamanga osinthika, komanso makina oziziritsa apamwamba amathandiziranso kuchepetsa kugwiritsa ntchito mphamvu.

Kubwezeretsa Kutentha kwa Zinyalala ndi Kugwiritsa Ntchito

Kubwezeretsa kutentha kwa zinyalala kumayimira kupita patsogolo kwakukulu kwa ma granulator ang'onoang'ono a PE. Panthawi yopangira granulation, makina amapanga kutentha ngati chinthu chochokera. M’malo molola kutentha kumeneku kutha, makina amakono amaulanda ndi kuugwiritsanso ntchito. Tekinoloje monga mapampu otentha kwambiri komanso makina osungiramo kutentha kwapang'onopang'ono pogwiritsa ntchito zida zosinthira magawo (PCMs) amapezanso kutentha kwa zinyalala zotsika ndikukweza kuti zigwiritsidwe ntchito popanga nthunzi kapena kutenthetsa malo. M'mafakitole owonetsera, makina opopera otentha osakanizidwa apezanso kutentha kopitilira 80%, ndikuchepetsa kudalira kutentha kwamagetsi mpaka kuchepera 20%. Izi sizimangowonjezera mphamvu zamagetsi zonse komanso zimapereka phindu lalikulu pazachuma, zomwe nthawi zambiri zimadzilipira pasanathe zaka zitatu. Kuphatikiza kwa kusungirako kutentha ndi mapampu otentha kumathandizira kugwira ntchito mosalekeza ndi kusuntha kwa katundu, kuchepetsanso mtengo wamagetsi ndikuchepetsa kutulutsa kwa CO2.

| Zamakono | Ntchito | Zokhudza Kugwiritsa Ntchito Mphamvu |

|---|---|---|

| Pampu Yotentha Yotentha Kwambiri | Imawonjezera kutentha kwa zinyalala kwa ntchito ya nthunzi | Amachepetsa kutentha kwamagetsi |

| Latent Heat Storage (PCM) | Amasunga ndikutulutsa kutentha ngati pakufunika | Imathandiza kusintha katundu |

| Zophatikiza Zophatikiza | Zimaphatikiza zonse kuti zitheke | Imapezanso 81.1% ya kutentha kwa zinyalala |

Ma granulator ang'onoang'ono a PE amakhazikitsa mulingo watsopano wogwiritsa ntchito mphamvu pakubwezeretsanso pulasitiki. Ukadaulo wawo wapamwamba wopulumutsa mphamvu umathandizira opanga kutsitsa mtengo, kukonza zokolola, ndikuthandizira zolinga zachilengedwe.

Ubwino wa PE Small Environmental Granulators mu 2025

Kuchepetsa Mtengo Wogwirira Ntchito ndi Kugwiritsa Ntchito Mphamvu

Opanga amawona ndalama zodziwikiratu akamagwiritsa ntchito ma granulator ang'onoang'ono a PE. Zitsanzo zoziziritsa mpweya zimachotsa kufunikira kwa madzi, zomwe zimapulumutsa ndalama zopangira madzi ndi kusunga zipangizo. Ma granulators awa amagwiritsa ntchito mphamvu zochepa poyerekeza ndi makina oziziritsidwa ndi madzi chifukwa cha kapangidwe kake kosavuta komanso kogwira bwino ntchito. Kusamalira kumakhala kosavuta, ndipo chiwopsezo cha kusokonekera kuchokera kumavuto amadzi amatsika. Oyendetsa amatha kuyendetsa makinawa m'malo opanda madzi kapena mpweya wabwino, zomwe zimapangitsa kuti makinawo azikhala okhazikika. Kuzizira kofanana kumapangitsanso kuti zinthu zikhale bwino komanso zimachepetsa zinyalala.

- Kuchita zoziziritsa mpweya kumachotsa mtengo wamadzi ndi kukonza kogwirizana.

- Kugwiritsa ntchito mphamvu zochepa kumatanthauza ndalama zazing'ono zamagetsi.

- Mapangidwe osavuta amachepetsa zosowa zokonza ndi nthawi yopuma.

- Kuchita kokhazikika m'malo ovuta kumatsimikizira zotuluka zodalirika.

- Ubwino wa mankhwala umapangitsa kuti pasakhale zinyalala zochepa komanso kuchita bwino kwambiri.

Kukhudza Kwachilengedwe ndi Kuchepetsa Mapazi a Carbon

Ma granulator ang'onoang'ono a PE amathandizira makampani kuchepetsa kukhudzidwa kwawo kwachilengedwe. Amadula mpweya wa carbon ndikugwiritsa ntchito mphamvu, kupanga pulasitiki processing kubiriwira.

| Ubwino Wachilengedwe | Tsatanetsatane |

|---|---|

| Kuchepetsa Kutulutsa kwa CO2 | 1.5 matani CO2 kuchepetsedwa pa toni imodzi ya ma pellets opangidwanso |

| Kuchepetsa Kugwiritsa Ntchito Mphamvu | 30% mphamvu zochepa zomwe zimagwiritsidwa ntchito ndi ma granulator atsopano otsika |

| Kuchepetsa Phokoso | 20dB kutsika kwaphokoso |

| Kupititsa patsogolo Mlingo Wobwezeretsanso | Kubwezeretsanso kutsekeka kumachepetsa kugwiritsa ntchito zinthu zopangira |

| Chitsanzo Chitsanzo - Magalimoto | Matani 300 apulasitiki atsopano amasungidwa chaka ndi chaka pokonzanso zinyalala zazikulu |

| Chitsanzo - Zaulimi | 85% kutembenuka mtima komwe alimi aku India amagwiritsa ntchito ma pellets ang'onoang'ono |

Makinawa amathandiziranso chuma chozungulira posintha zinyalala zapulasitiki kukhala ma granules ogwiritsidwanso ntchito. Njira imeneyi imachepetsa zinyalala zotayira m’nthaka komanso imateteza zachilengedwe.

Kugwirizana ndi Kusintha kwa Miyezo ya Makampani

Ma granulator ang'onoang'ono a PE amathandizira makampani kukwaniritsa malamulo okhwima a chilengedwe m'magawo ambiri. Makinawa amathandizira kukonzanso ndikuchepetsa kugwiritsidwa ntchito kwa zinyalala, zomwe zimagwirizana ndi mapulogalamu aboma osataya ziro. Mitundu yambiri imakumana ndi miyezo yapadziko lonse lapansi ngati ISCC PLUS, yomwe imatsata kagwiritsidwe ntchito kokhazikika ndikuwonetsetsa kuti anthu akutsata zolinga za chikhalidwe ndi chilengedwe. Mapangidwe awo osinthika amafanana ndi ntchito zazikulu ndi zazing'ono, kuthandiza mabizinesi kuti agwirizane ndi kusintha kwa malamulo. Advanced automation ndizopulumutsa mphamvuzikhale zosavuta kutsatira malamulo atsopano pa mpweya ndi phokoso. Makampani aku North America ndi ku Europe amagwiritsa ntchito ma granulatorswa kuti athandizire zolinga zazachuma komanso kukwaniritsa miyezo yapadziko lonse lapansi.

Ma granulator ang'onoang'ono a PE amapeza mphamvu zamagetsi pogwiritsa ntchito mapangidwe otsika kwambiri, mawonekedwe osinthika, komanso ukadaulo wapamwamba wobwezeretsanso. Makinawa amathandizira mafakitale kutsitsa mtengo, kuchepetsa zinyalala, ndikuthandizira chuma chozungulira. Makampani omwe amasankha ma granulator awa amathandizira kukhazikika, kukwaniritsa malamulo, ndikupanga tsogolo labwino.

FAQ

Kodi granulator yaing'ono ya PE imapulumutsa bwanji mphamvu?

Granulator imagwiritsa ntchito ma motors apamwamba kwambiri komanso makina apamwamba kwambiri. Izi zimachepetsa kugwiritsa ntchito magetsi komanso zimachepetsa zinyalala panthawi yopanga pulasitiki.

Langizo:Kusamalira nthawi zonse kumathandiza kuti magetsi azikhala ochuluka.

Kodi granulator ingagwire mitundu yosiyanasiyana ya zinyalala zapulasitiki?

Inde. Makinawa amathandizira zida zosiyanasiyana zapulasitiki. Othandizira amatha kusintha makonda amtundu uliwonse, kuwonetsetsa kuti granulation yosasinthika komanso kutulutsa kwabwino.

Kodi granulator imafuna chisamaliro chotani?

Oyendetsa ayenera kuyang'ana ma injini, zosefera zoyera, ndi kuyang'ana zodula nthawi zonse. Kuwongolera kosavuta ndi magawo osinthika kumapangitsa kukonza kwanthawi zonse kukhala kosavuta komanso kosavuta.

Nthawi yotumiza: Jul-17-2025