Mgolo wa pulasitiki wopangira jakisoni wa pulasitiki umakhala ndi gawo lalikulu pakukonza mtundu wosungunuka komanso kuthamanga kwa kupanga. Mainjiniya amayang'ana kwambiri paJekeseni Womangira Barrelkupanga kupititsa patsogolo ntchito. Amagwiritsa ntchito zipangizo zosiyanasiyanaSingle Screw Plastic Extruder MachinendiSingle Screw Extrusion Machine. Chisankho chilichonse chimathandiza makina kukonza mapulasitiki bwino.

Pulasitiki Injection Molding Screw Barrel Kapangidwe ndi Magwiridwe

Mitundu ya Mimbi: Bimetallic vs. Integral

Kusankha mbiya yoyenera kungapangitse kusiyana kwakukulu momwe aPulasitiki jakisoni womangira screw mbiyaamachita. Migolo ya Bimetallic imagwiritsa ntchito chitsulo cholimba chokhala ndi zitsulo zolimba mkati. Kapangidwe kameneka kamasunga zinthu zamtengo wapatali ndipo amalola opanga kuti alowe m'malo mwa nsalu yokhayokha, zomwe zimapangitsa kukonza kukhala kosavuta komanso kotsika mtengo. Kukwanira pakati pa mbiya ndi mbiya kuyenera kukhala kolondola kuti kutentha kuyende bwino komanso kupewa kuyenda. Migolo ya Bimetallic imagwira ntchito bwino pokonza mapulasitiki otsekemera kapena olimbikitsidwa chifukwa amakana kuvala komanso amakhala nthawi yayitali.

Migolo ya Integral imapangidwa ngati chidutswa chimodzi. Izi zimawapatsa kulondola kwambiri komanso ngakhale kugawa kwa kutentha pambiya. Amapangitsa kuti zikhale zosavuta kukhazikitsa ndi kusunga makina otenthetsera ndi ozizira. Komabe, amafunikira kuwongolera kokhazikika kopanga kuti akhalebe apamwamba. Poyerekeza ziwirizi, migolo yophatikizika imapereka chisamaliro chosavuta komanso kutentha kwa yunifolomu, pomwe migolo ya bimetallic imapereka kukana kovala bwino komanso kusinthika kwagawo kosavuta.

| Magwiridwe Mbali | Integral Barrel | Bimetallic Barrel |

|---|---|---|

| Zomangamanga | Chidutswa chimodzi, kupangidwa kwapamwamba kwambiri | Base mbiya ndi replaceable aloyi zitsulo bushing |

| Kugawa Kutentha | Kugawa kutentha kofanana motsatira mbiya | Kuwongolera kutentha kumasungidwa ngati kukwanira kwa bushing kuli kolondola |

| Valani Kukaniza | Standard kuvala kukana | Kuwonjezeka kwa kukana kuvala chifukwa cha chitsulo cha alloy |

| Kusamalira | Kuyika kosavuta ndi kukonza makina otenthetsera / ozizira | Bushing yosinthika imalola kusintha kosavuta kwa gawo |

| Kugwiritsa Ntchito Zinthu Zakuthupi | Imafunika kulondola kwambiri komanso mtundu wazinthu | Imateteza zinthu zamtengo wapatali pogwiritsa ntchito chitsulo cha alloy pokhapokha pazitsulo |

Migolo ya bimetallic nthawi zambiri imakhala nthawi yayitali kuposa migolo yophatikizika, makamaka ikakonza zida zolimba. Mapangidwe awo amachepetsa nthawi yocheperako komanso ndalama zosinthira, zomwe zimathandiza kuti kupanga kuyende bwino.

Screw Geometry: Ratio ya L/D, Compression Ratio, ndi Flight Design

Zithunzi za geometrywononga mkati mwa mbiya ya pulasitiki yopangira jekeseniamaumba momwe mapulasitiki amasungunuka ndi kusakanikirana. Chiŵerengero cha L / D, chomwe chimafanizira kutalika kwa wononga ndi m'mimba mwake, chimakhudza kusungunuka kofanana ndi kusakaniza. Zomangira zazitali (chiŵerengero cha L/D chapamwamba) chimapatsa pulasitiki nthawi yochulukirapo kuti isungunuke ndi kusakaniza, zomwe zimapangitsa kuti zinthu zikhale bwino. Komabe, ngati screwyo ndi yayitali kwambiri, imatha kuyambitsa kuwonongeka kwamafuta, makamaka ndi mapulasitiki osamva kutentha. Zida monga PVC ndi POM zimafunika zomangira zazifupi kuti zisawonongeke, pomwe mapulasitiki odzaza magalasi kapena owoneka bwino amapindula ndi zomangira zazitali komanso madera osakanikirana.

- Zida zokhazikika bwino zamatenthedwe zimagwiritsa ntchito zomangira zazitali kuti zisakanize bwino.

- Mapulasitiki osamva kutentha amafunikira zomangira zazifupi kapena ulusi wapadera.

- Zomangira zanthawi zonse (L/D ~20:1) zimagwirizana ndi mapulasitiki wamba koma zimatha kuwonetsa mitundu yosiyanasiyana.

- Zomangira zotchinga (L/D ~ 24:1) zimathandizira kusakanikirana kwa mapulasitiki olimba.

- Zomangira zolekanitsa (L/D ~18:1) zimathandizira zida zomwe sizimva kutentha kuti zisawonongeke.

- Zosakaniza zosakaniza (L/D ~ 22:1) zimapereka yunifolomu yosungunuka pamapulasitiki apadera.

Chiŵerengero cha kuponderezana chimayesa kuchuluka kwa wononga pulasitiki. Mapulasitiki apamwamba kwambiri amafunikira chiŵerengero chapamwamba cha kuponderezana kuti asungunuke ndi kusakaniza bwino. Kusintha chiŵerengero cha kuponderezana kumathandizira kulinganiza momwe zinthu zimayendera komanso mtundu wazinthu. Opanga nthawi zambiri amayang'anira ndi kukonza zomangira zomangira kuti zigwirizane ndi zosowa za zinthuzo.

Mapangidwe a ndege amafunikiranso. Zomangira zokongoletsedwa bwino bwino zimasungunuka bwino pofananiza ndi kayendedwe ka polima. Makina oyendetsedwa a Melt Delivery amathandizira kuwongolera kutentha ndi kukhuthala, kuchepetsa chiopsezo cha kuwonongeka. Zomangira zosakaniza ndi zomangira zotchingira zimasungunuka kuti zisungunuke ndikuteteza madontho akufa, zomwe zimalepheretsa pulasitiki kutenthedwa kapena kutayika.

Mapangidwe a Zinthu ndi Kuchiza Pamwamba

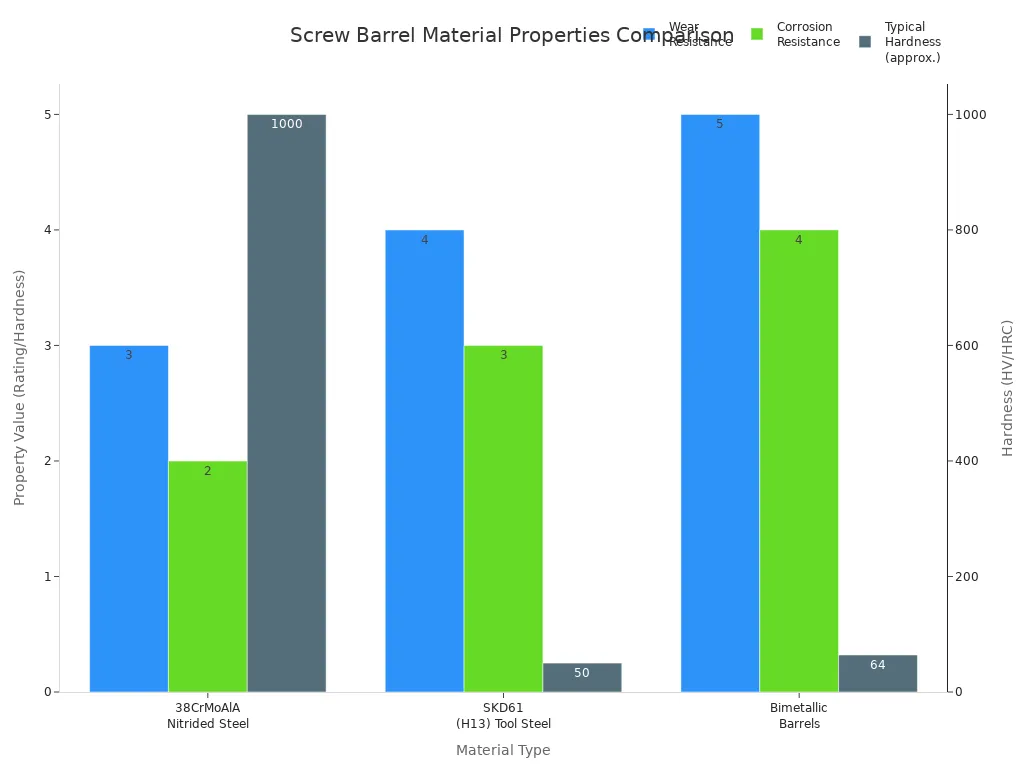

Zida zomwe zimagwiritsidwa ntchito popanga mbiya ya Plastic Injection molding screw zimakhudza kulimba kwake komanso magwiridwe ake. Chitsulo cha nitrided chimapereka kuuma kwabwino komanso kuvala kukana kwa mapulasitiki wamba. Migolo ya bimetallic imaphatikiza maziko achitsulo ndi liner ya alloy, zomwe zimapereka kuvala bwino komanso kukana dzimbiri kwa mapulasitiki olimba kapena odzaza. Chida chitsulo amapereka mphamvu mkulu ndi kuvala kukana kwa chilengedwe kwambiri.

| Mtundu Wazinthu | Katundu Wofunika & Ubwino | Zoipa & Zochepa | Mapulogalamu Abwino Kwambiri |

|---|---|---|---|

| Nitrided Steel | High pamwamba kuuma; bwino kuvala kukana kwa utomoni wosadzazidwa; zotsika mtengo | Kukana dzimbiri kosakwanira; zosayenera kwa abrasive / mankhwala utomoni | Zinthu zopangidwa ndi utomoni monga polyethylene, polypropylene |

| Migolo ya Bimetallic | Chitsulo chothandizira ndi liner alloy; kuvala bwino komanso kukana dzimbiri; moyo wautali | Zokwera mtengo; akhoza kukhala overkill ntchito wamba | Nayiloni zodzaza galasi, ABS osagwira moto, PVC, ma polima aukali |

| Ma Aloyi Opangidwa ndi Nickel | Kukana dzimbiri kwapadera; zabwino kwa malawi-retardant ndi halogenated resins | Zosalimba kuposa ma aloyi opangidwa ndi chitsulo; kukana kuvala pansi | Mankhwala aukali ma polima |

| Ma Aloyi Opangidwa ndi Iron | Kulimba kwapamwamba ndi kukana kuvala | Kutsika kwa dzimbiri kuposa ma aloyi opangidwa ndi nickel | Abrasive, odzazidwa kwambiri resins |

| Chida Chitsulo | Kuuma kwapadera ndi mphamvu; mkulu kuvala kukana | Mtengo wapamwamba; atengeke ndi dzimbiri popanda zokutira | Malo ovala kwambiri, ntchito zotulutsa kwambiri |

| Migolo Yapadera Yokutidwa | Zovala monga tungsten carbide kapena chrome plating zimathandizira kuti zisamawonongeke komanso kuti tisawonongeke | Amawonjezera mtengo ndi zovuta; ❖ kuyanika kumasiyanasiyana | Mapulogalamu opangira utomoni kapena mwamakani |

Thandizo lapamtunda monga nitriding ndi chrome plating kulimbikitsa kukana kuvala komanso moyo wautali. Nitriding imatha kuwirikiza kawiri kapena katatu moyo wautumiki wa zomangira ndi migolo. Kuyika kwa Chrome kumawonjezera kuuma komanso kukana dzimbiri, koma nitriding nthawi zambiri imachita bwino pakakhala zovuta. Kupopera mbewu mankhwalawa molybdenum pamodzi ndi nitriding kumapereka chitetezo chochulukirapo. Kuchita bwino ndi kukonza bwino kumathandiza kukulitsa mapindu awa.

Kudyetsa Port ndi Venting Design

Mapangidwe a doko lodyetsera amawongolera momwe pulasitiki imalowera mumgolo. Kuwongolera bwino kwa kutentha pa doko lodyerako kumapangitsa kuti kukhuthala kwa zinthu kukhale kosasunthika, komwe kumathandizira kuti madzi aziyenda komanso kudyetsedwa kosasintha. Ma vacuum loaders ndi zolandirira hopper amaonetsetsa kuti zinthu zikuyenda bwino pamakina, kuchepetsa kuipitsidwa ndi kutayikira. Kukonzekera uku kumapangitsa kuti kapangidwe kake kakhale kokwera komanso kadyedwe kosasintha.

- Vacuum loaders amakwera molunjika pakhosi la makina, kuchepetsa kuipitsidwa.

- Olandira Hopper amagwiritsa ntchito mphamvu yokoka kudyetsa zinthu, kufewetsa ndondomekoyi.

Mapangidwe a mpweya wolowera mpweya amathandizanso kwambiri. Zomangira zomangira zimakhala ndi madera apadera omwe amachotsa chinyezi ndi kugwedezeka panthawi yokonza. Izi ndizofunikira pazinthu za hygroscopic ndi mapulasitiki obwezerezedwanso. Madoko olowera mpweya amalola mpweya ndi chinyezi kuthawa, kuteteza zolakwika ndikusunga upangiri wa extrusion wapamwamba.

Langizo: Malo odyetserako madzi oyenerera komanso makonzedwe olowera mpweya amathandiza kuti zinthu zizipangika bwino komanso kuti zinthu zikhale bwino, makamaka pogwira ntchito ndi mapulasitiki okonzedwanso kapena osavuta kumva.

Zotsatira za Mapangidwe a Plastic Injection Molding Screw Barrel Design

Sungunulani Quality ndi Homogeneity

Pulasitiki yopangidwa bwino ndi jekeseni wopangira screw barrel imathandizira kuti ikhale yosalala komanso yosungunuka. Geometry ya screw, kuphatikiza zakecompression rationdi mawonekedwe a madera ake, amalamulira momwe mapepala apulasitiki amasungunulira ndi kusakanikirana. Pamene chiŵerengero cha kuponderezana chikufanana ndi zinthu, kusungunuka kumayenda mofanana. Izi zimachepetsa mavuto monga splay marks kapena kusungunuka kosakwanira. Thezone chakudyakusuntha ndi kutenthetsa ma pellets, malo oponderezedwa amasungunuka ndikusindikiza zinthuzo, ndipo malo owerengera amaonetsetsa kuti kusungunula kumakhala kofanana. Zinthu monga kuya kwa tchanelo ndi zigawo zosakanikirana zimathandizira kutentha kwa screw ndikuphatikiza pulasitiki. Zomangira zotchingira zimatha kulekanitsa pulasitiki yolimba komanso yosungunuka, zomwe zimapangitsa kusungunuka kukhala kothandiza komanso kupulumutsa mphamvu.

Pamene kusungunuka kuli yunifolomu, mankhwala omaliza amawoneka bwino komanso amagwira ntchito bwino. Kusakaniza kosakwanira kungayambitse mikwingwirima yamitundu, mawanga ofooka, kapena kusintha kwa magawo ena. Good Sungunulani homogeneity kumatanthauza zochepa zolakwika ndi mbali zodalirika. Othandizira amathanso kugwiritsa ntchito masensa kuti awonere kusungunuka kwabwino ndikusintha makonda kuti apeze zotsatira zabwino.

- Kusakaniza kosasungunuka kumayambitsa mikwingwirima yamitundu ndi mawanga ofooka.

- Kusungunuka kwabwino kumabweretsa kukula kwa gawo limodzi ndi mphamvu.

- Kusungunuka kwabwino kumadalira kutentha kwa mbiya, kuthamanga kwa screw, ndi backpressure.

Zindikirani: Kusunga kutentha kwa sungunuka ndi kufananiza wononga phula ndi mtundu wa pulasitiki kumathandiza kupeŵa zolakwika ndikupangitsa kuti chinthucho chikhale chokwera.

Kusakaniza Mwachangu ndi Nthawi Yozungulira

Kusakaniza bwino kumadalira mawonekedwe a wononga ndi mawonekedwe apadera. Pamene wonongayo ikutembenuka, imakankhira ndi kupindika pulasitiki, kupanga mphamvukukameta ubweya mphamvu. Kusakaniza zigawo pafupi ndi nsonga, monga mapini kapena maulendo apandege, kumathandiza kusakaniza kusungunuka. Chochita ichi chimafalitsa mtundu ndi zowonjezera mofanana, kotero kuti gawo lomaliza limawoneka losalala komanso lofanana. Zomangira zotchingira zimagwiritsa ntchito ulendo wachiwiri kulekanitsa pulasitiki yosungunuka ndi tinthu tolimba, kufulumizitsa kusungunuka ndikuteteza tinthu tosasungunuka.

- Screw geometry imayang'anira momwe ma pellets amasuntha, kusungunuka, ndi kusakanikirana.

- Kusakaniza magawo kumapangitsa kuyenda kozungulira,kuphatikiza 95%wa zinthu mwamsanga.

- Zotchingira zotchinga ndi mapangidwe apadera amathandizira kufalitsa utoto ndi zowonjezera.

Kusakaniza bwino kumakhudzanso nthawi yozungulira. Kuthamanga komanso kusungunuka kwambiri kumatanthauza kuti makina amatha kuyenda mozungulira nthawi yocheperako. Kugwiritsa ntchito zomangira zotchinga, zomangira zazikulu zokulirapo, kapena ma groove akuya kumawonjezera kuthamanga kwa pulasitiki. Kukweza liwiro la screw (potetezedwa kuzinthu) ndikuchepetsa kupsinjika kwammbuyo kumatha kufupikitsa nthawi yozungulira. Makina otenthetsera otsogola ndi oziziritsa amasunga mbiya pa kutentha koyenera, kumathandizira kuti mbali zina zizizizire mwachangu komanso kuti zinthu ziziyenda bwino.

- Mapangidwe okhathamiritsa a screw barrel amalepheretsa kutsekeka ndi kuchedwa.

- Makina otenthetsera bwino ndi kuziziritsa amathandizira kuti zigawo zikhazikike mwachangu.

- Zida zolimba ndi zokutira zimachepetsa nthawi yokonzanso.

Valani Kukaniza ndi Kusamalira

Wear ndizovuta kwambiri pa mbiya iliyonse ya Plastic Injection molding screw. Ma abrasive fillers, mapulasitiki owononga, komanso kupanga kwautali kumatha kuwononga wononga ndi mbiya. Mitundu yovala yodziwika bwino imaphatikizapo kuvala zomatira, kuvala kwa abrasive, ndi dzimbiri. Mwachitsanzo, kuvala kwa abrasive kumachitika pamene zodzaza zolimba monga zitsulo zamagalasi zipaka chitsulo. Zovala zowononga zimachokera ku mankhwala apulasitiki monga PVC.

| Valani Mechanism | Kufotokozera | Mapangidwe Ochepetsa Njira |

|---|---|---|

| Zovala Zomatira | Zitsulo pamwamba kukhudzana ndi kusamutsa zinthu. | Gwiritsani ntchito ma alloys olimba, fufuzani kugoletsa, onetsetsani kuti zinthu zikugwirizana. |

| Abrasive Wear | Kumeta ubweya kuchokera ku pellets kapena fillers. | Gwiritsani ntchito ma alloys olimba, pewani zodzaza ndi abrasive, sungani chakudya choyera. |

| Zovala Zowononga | Kuukira kwa mankhwala kuchokera ku mapulasitiki ena. | Gwiritsani ntchito zinthu zolimbana ndi dzimbiri, pewani mankhwala owopsa. |

| Mavuto a Kulinganiza | Kusakaniza kumayambitsa kupukuta ndi kuvala kosiyana. | Onetsetsani kuwongoka ndi kuyanika koyenera. |

Kusankha kwakuthupi ndi chithandizo chapamwamba kumapanga kusiyana kwakukulu. Nitriding yamadzimadzi imawonjezera kulimba kwapamwamba komanso kukana kuvala. Migolo ya bimetallic yokhala ndi zingwe zapadera imakhala nthawi yayitali, makamaka ndi mapulasitiki olimba. Kuyang'anitsitsa nthawi zonse ndi kukonza njira zodzitetezera, monga kuyeretsa ndi kuyang'ana momwe akuyendera, kumathandiza kuthetsa mavuto mwamsanga. Zovala zapamwamba ndi zida zatsopano zimatha kukulitsa moyo wa migolo mpaka 40%, kutsitsa mtengo wokonza ndikuchepetsa nthawi yopuma.

- Kukonza pafupipafupi kumadalira mbiya zakuthupi ndi zokutira.

- Kusamalira kodziletsa komanso kuwunika pafupipafupi kumawonjezera moyo wa migolo.

- Thandizo lapamwamba lapamwamba limachepetsa kukonzanso ndikusintha.

Kusintha kwa Zida Zosiyanasiyana ndi Ntchito

Mapangidwe osinthika a screw barrel amalola opanga kupanga mitundu yambiri ya mapulasitiki. Screw geometry, monga kutalika, phula, ndi kuya kwa tchanelo, zitha kusinthidwa kuti zigwirizane ndi zida zosiyanasiyana. Zolinga zonse, zotchinga, ndi zosanganikirana zimagwira ntchito bwino ndi mapulasitiki ena. Njira zoziziritsira, monga ngalande zamadzi, zimasunga mbiya pa kutentha koyenera kwa chinthu chilichonse.

- Mapangidwe a screw ndi geometryphatikizani mapulasitiki osiyanasiyana.

- Machitidwe ozizira amalepheretsa kutentha.

- Aloyi amphamvu kwambiri ndi zokutira zimagwira ntchito zovuta.

Mapangidwe osinthika amathandizanso kukhala kosavuta kusinthana pakati pa ntchito. Zina monga ma adapter ochotsa mwachangu ndi zopumira zomata zimathandizira ogwiritsa ntchito kusintha zomangira mwachangu. Zowongolera zosinthika zimagwiritsa ntchito masensa ndi kuphunzira pamakina kuti zisinthe makonzedwe munthawi yeniyeni. Izi zimachepetsa kusintha kwamanja ndikufulumizitsa kusintha, kotero kupanga kumatha kusintha kuchokera ku chinthu chimodzi kupita ku china ndi nthawi yochepa.

Langizo: Mapangidwe osinthika a mbiya zomangira amathandiza mafakitale kugwira mitundu yambiri ya mapulasitiki ndikusintha ntchito mwachangu, kupangitsa kupanga kukhala kosavuta komanso kothandiza.

Kuthetsa Mavuto Omwe Amagwira Ntchito

Ngakhale ndi mapangidwe abwino kwambiri, mavuto amatha kuchitika. Nkhani wamba mongakuvala kwambiri, mavuto a kutentha, kutsekeka, phokoso, ndi zolakwika zosakaniza mitundu. Vuto lirilonse liri ndi zifukwa zake ndi njira zake.

| Nkhani Yantchito | Kufotokozera ndi Zizindikiro | Zoyambitsa ndi Mayankho |

|---|---|---|

| Kuvala Mopambanitsa | Kutuluka kwa zinthu, khalidwe loipa, kutentha kwambiri, phokoso | Gwiritsani ntchito migolo ya bimetallic, ma alloys olimba, kuyeretsa nthawi zonse, kuyanjanitsa koyenera |

| Kuwongolera Kutentha | Kusintha kwa mtundu, kuphulika, kuphulika, kuphulika | Gawani mbiya m'magawo, gwiritsani ntchito masensa, kutenthetsa pang'onopang'ono, ma jekete otsekera |

| Blockage ndi Kumanga-Up | Kuthamanga kwakukulu, kuyenda kosauka, madontho akuda | Tsukani ndi mankhwala oyeretsa, kuthamanga koyenera, mbiya yosindikizira panthawi yopuma |

| Phokoso kapena Kugwedezeka | Phokoso lalikulu, kugwedezeka, kukangana | Yang'anani mayanidwe, mayendedwe, ntchito kugwedera damping, kudzipatula zigawo zikuluzikulu |

| Kusakaniza kwamitundu / kuipitsidwa | Mitundu yamitundu, mithunzi yosagwirizana, kuipitsidwa | Gwiritsani ntchito zinthu zotsuka, kuyeretsa pafupipafupi, kukhathamiritsa kapangidwe ka screw, makina osindikizira panthawi yotseka |

Othandizira amatha kuthetsa mavuto ambiri potsatira njira zingapo zofunika:

- Konzani masinthidwe a screw ndi kutentha kwa migolo.

- Yang'anirani ndikusintha kutentha ndi liwiro la screw.

- Sanjani zodyetsa ndi kupewa kulumikiza zinthu.

- Yang'anani zomangira ndi migolo kuti zivale, makamaka m'malo opsinjika kwambiri.

- Gwiritsani ntchito kukonza zolosera kukonzekera kukonza ndikuchepetsa nthawi.

- Khalani ndi screw screwndi kukonzanso kangapo kokha.

- Phunzitsani oyendetsa galimoto kuti awone zizindikiro zochenjeza.

Zindikirani:Kuyeretsa nthawi zonse, kuthira mafuta moyenera, ndikuwunika mosamalathandizirani kuti mbiya ya Plastic Injection molding screw ikuyenda bwino ndikukulitsa moyo wake.

Kukonzanitsa kamangidwe ka pulasitiki wa jekeseni wopangira screw barrel kumawonjezera kusungunuka ndi moyo wa zida. Pamene opanga kusankhakumanja mbiya mtundu, wononga geometry, ndi zipangizo, amawona kuyenda kosalala, kusakanikirana bwino, ndi zolakwika zochepa. Kukonza nthawi zonse, kuphatikizapo kuyeretsa ndi kuyendera, kumapangitsa kuti makina aziyenda bwino komanso kumachepetsa mtengo.

FAQ

Kodi phindu lalikulu la bimetallic screw barrel ndi chiyani?

Migolo ya Bimetallic imakana kuvala kuchokera ku mapulasitiki olimba. Amakhala nthawi yayitali ndikuchepetsa nthawi yokonza.

Kodi opareshoni ayenera kuyang'ana kangati mbiya?

Ogwira ntchito ayenera kuyang'ana mbiya ya screw mwezi uliwonse. Kuwunika pafupipafupi kumathandizira kuti makina azigwira mwachangu komanso kuti makina aziyenda bwino.

Kodi mbiya imodzi yowononga ingagwire ntchito ndi mitundu yambiri ya mapulasitiki?

| Mtundu wa mbiya | Kusinthasintha |

|---|---|

| General Cholinga | Zabwino |

| Chotchinga | Zabwino kwambiri |

| Kusakaniza | Zabwino kwambiri |

Mgolo wopangidwa bwino umatha kugwira mapulasitiki ambiri, koma zida zina zimafunikira zida zapadera.

Nthawi yotumiza: Aug-25-2025