Chowonjezera cha laboratory single screw extruder chimagwiritsa ntchito screw yozungulira kusungunula, kusakaniza, ndi kupanga ma polima mkati mwa mbiya yotenthedwa. Ofufuza amadalirawotuluka wononga wononga extruder, makina omangira amodzi,ndimakina opanda madzi granulatorkukwaniritsa mulingo woyenera kusakaniza ndi otetezeka, ogwira processing. Kafukufuku amasonyeza kutiscrew liwiro ndi kutenthazimakhudza kwambiri khalidwe la mankhwala ndi chitetezo.

Zigawo Zazikulu za Single Screw Extruder

Chipika

Zowonongandi mtima wa single screw extruder. Imazungulira mkati mwa mbiya ndikusunthira polima patsogolo. Chophimbacho chimasungunuka, kusakaniza, ndikukankhira zinthuzo ku fa. Kapangidwe ka screw, kuphatikizira m'mimba mwake, chiŵerengero cha kutalika kwa m'mimba mwake, ndi chiŵerengero cha kuponderezana, zimakhudza momwe polima amasungunuka ndi kusakanikirana. Chophimba chopangidwa bwino chimapangitsa kusungunuka kwachangu komanso kuchita bwino. Ma grooves pa screw kapena mbiya amatha kuwonjezera liwiro losungunuka ndikuthandizira kuwongolera. Kuthamanga kwa wononga kumasinthanso kuchuluka kwa kusakaniza ndi kutentha komwe kumapangidwa.

Langizo: Kusintha liwiro la screw kungathandize kuwongolera kutentha kwasungunuka ndi mtundu wazinthu.

Mgolo

Mgoloimazungulira wononga ndikugwira polima pamene ikuyenda. Mgolowu uli ndi madera otentha osiyanasiyana. Chigawo chilichonse chikhoza kukhazikitsidwa ku kutentha kwapadera kuti zithandize kusungunula polima mofanana. Mwachitsanzo, gawo loyamba likhoza kukhala lozizira kwambiri kuti lithandizire kusuntha polima wolimba, pomwe madera akutsogolo amakhala otentha kwambiri kusungunula zinthuzo. Kuwongolera kutentha kwabwino mu mbiya ndikofunikira kuti pakhale kuyenda bwino komanso mtundu wazinthu.Thermocouples amayesa kutentha mkati mwa mbiyakuti ndondomekoyi ikhale yokhazikika.

- Kutentha kwa migolo kumatengera mtundu wa polima ndi kapangidwe ka screw.

- Zotulutsa zamakono nthawi zambiri zimakhala ndi magawo atatu kapena kuposa kutentha.

- Gawo la chakudya liyenera kukhala lofunda koma losatentha kwambiri kuti zinthu zisamamatire.

The Heater System

Dongosolo la chotenthetsera limasunga mbiya pa kutentha koyenera. Ma heater amayikidwa pambali pa mbiya ndikuwongoleredwa ndi masensa. Dongosololi limatha kusintha gawo lililonse kuti ligwirizane ndi zosowa za polima. Kuwongolera bwino kwa chotenthetsera kumathandiza kupewa zovuta monga kuyaka kwa zinthu kapena kusungunuka kosafanana. Dongosolo la chotenthetsera limagwira ntchito ndi dongosolo lowongolera kuti njirayo ikhale yotetezeka komanso yothandiza.

The Die

Chovalacho chimapanga polima wosungunuka pamene chimachoka pa screw extruder imodzi. Mapangidwe amafa amakhudza mawonekedwe a chinthu chomaliza, pamwamba, ndi kukula kwake. Kufa kwabwino kumapereka kusalala, ngakhale kuyenda komanso kumathandizira kupanga zinthu zokhala ndi miyeso yolondola. Chovalacho chiyenera kupirira kutentha koyenera ndi kupanikizika kuti zisawonongeke. Kusintha kwa kutentha kwa kutentha kapena kutuluka kungasinthe khalidwe la mankhwala.

- Kuthamanga kwamtundu umodzi komanso kutsika kochepa kwapang'onopang'ono pakutuluka ndikofunika kuti pakhale mtundu wabwino.

- Die channel geometry ndi kayendedwe ka kayendedwe kake zimakhudza kulondola kwa mawonekedwe a malonda.

The Control System

Dongosolo lowongolera limayang'anira ntchito ya screw extruder imodzi. Imayang'anira kutentha, kuthamanga, kuthamanga kwa screw, ndi kuchuluka kwa chakudya. Othandizira amagwiritsa ntchito dongosolo lolamulira kuti akhazikitse ndikusintha magawo a ndondomeko. Kuwunika nthawi yeniyeni kumathandiza kuti ntchitoyi ikhale yokhazikika komanso yotetezeka. Dongosolo lowongolera limathanso kusunga maphikidwe a ma polima osiyanasiyana, kupangitsa kuti zikhale zosavuta kubwereza kuthamanga bwino.

Mitundu ya Single Screw Extruder Yogwiritsa Ntchito Laboratory

Zokonda za labotale zimafunikira mitundu yosiyanasiyana ya ma extruder kuti akwaniritse zosowa zapadera za kafukufuku. Mtundu uliwonse umapereka mawonekedwe apadera ndi zabwino zake polima polima.

Vented Single Screw Extruder

Chotulutsa chopopera chotulutsa chimodzi chimagwiritsa ntchito amapangidwe awiri wononga. Kapangidwe kameneka kamachepetsa ma torque ndi mphamvu zamahatchi kwinaku akusunga zotulukapo ndi liwiro la screw. Njira yolowera mpweya imachotsa chinyezi ndi mpweya kuchokera ku polima kusungunuka. Izi ndizofunikira pokonza mapulasitiki omwe amamwa madzi. Kuchotsa zosinthika izi kumalepheretsa zolakwika monga splay ndi zida zofooka zamakina. Khomo lolowera mpweya nthawi zambiri limagwira ntchito popanda vacuum, zomwe zimathandiza kuchotsa mpweya pochepetsa kuthamanga. Zomangira ziwirizi zimathandizanso kusanganikirana mwa kukanikiza ndi kutsitsa pulasitiki. Izi zimapanga kusungunuka kofananako. Oyendetsa ayenera kulinganiza zotulutsa pakati pa magawo awiriwa kuti asasefukire kapena kusefukira kwa mpweya. Zinthu izi zimapangitsa kuti potulutsa mpweya umodzi wononga extruder kothandiza ndi odalirika ntchito zasayansi.

Chidziwitso: Kutulutsa kokhazikika komanso kugwiritsa ntchito mphamvu pang'ono kumayika ma extruder otuluka m'malo ofufuzira.

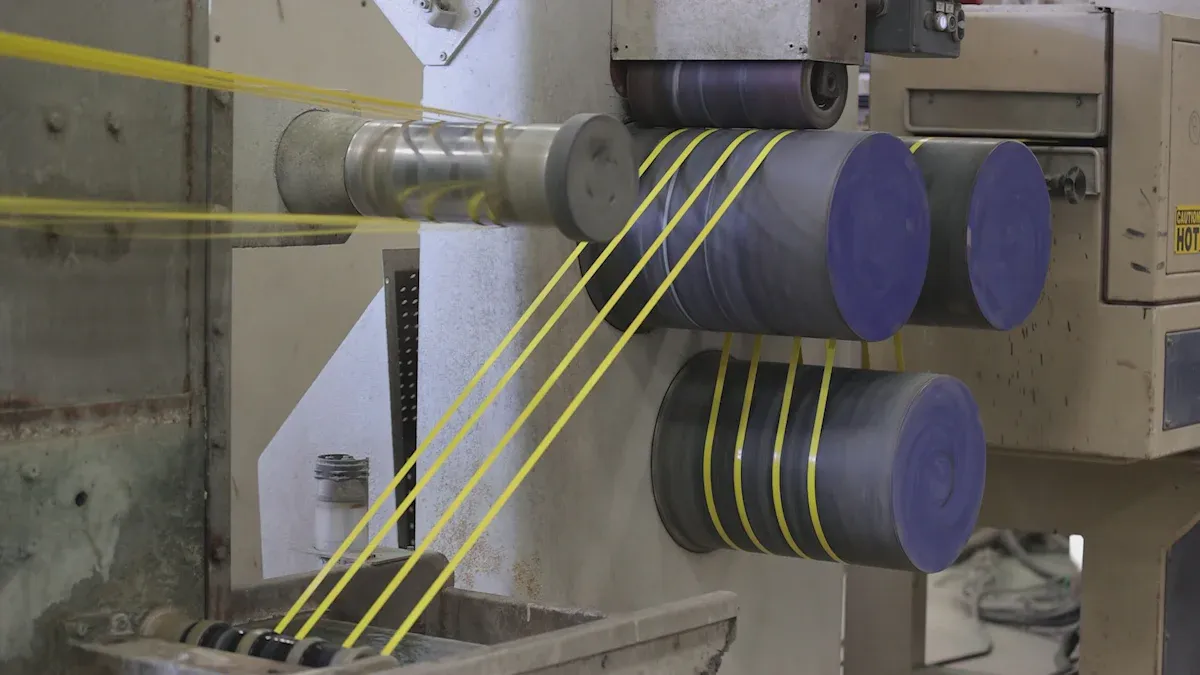

Single Screw Machine

Makina omangira amodzi amakhala ndi ma extruder osiyanasiyana osungunuka, kusakaniza, ndi kupanga ma polima. Makinawa amapereka mapangidwe osavuta komanso osavuta kugwiritsa ntchito. Ochita kafukufuku amatha kuwongolera kumeta ubweya ndi kutentha bwino, zomwe zimathandiza popanga ma polima ndi ntchito zotulutsa. Makina omangira amodzi amagwira ntchito bwino popanga machubu, filimu, ndi zinthu zina zosavuta. Amabwera m'makulidwe osiyanasiyana komanso masinthidwe kuti agwirizane ndi zosowa zosiyanasiyana za kafukufuku.

| Mtundu wa Extruder | Mfungulo ndi Ubwino wake | Kugwiritsa Ntchito ndi Kukwanira |

|---|---|---|

| Single Screw Extruders | Kukonzekera kosavuta, kulamulira bwino, ntchito yosavuta | Tubing, filimu, zoyambira polima formulations |

| Twin Screw Extruders | Zosakaniza zapamwamba, zosunthika, zopangira intermeshing | Kuphatikiza, zida zovuta, mankhwala |

| Miniature / Micro Extruders | Zochepa, zotsika mtengo, zodalirika | R&D, prototyping, zitsanzo zochepa zakuthupi |

Makina Opanda Madzi a Granulator

Makina a granulator opanda madzi amasintha zinthu zapulasitiki kukhala ma granules osagwiritsa ntchito madzi. Tekinolojeyi imapangitsa kuti mphamvu ziziyenda bwino komanso zimachepetsa chilengedwe. Njirayi imapangitsa kuti ma granules akhale owuma komanso aukhondo, zomwe zimapindulitsa njira zina zopangira. Makina a granulator opanda madzi amagwira mitundu yambiri ya ma resin apulasitiki. Amathandizira ochita kafukufuku kupanga ma granules apamwamba kwambiri poyesa ndi chitukuko.

Pang'onopang'ono Polima Extrusion Njira

Kudyetsa Zinthu za Polima

Njira yowonjezera imayamba ndikudyetsa zinthu za polima zosaphika mu hopper ya chakudya. Hopper imatsimikizira kugawa ndikuletsa kutsekeka, zomwe zimathandiza kuti pakhale kutulutsa kokhazikika. Zowononga mkati mwa mbiya zimayamba kusinthasintha, kukokera ma pellets a polima kapena ufa patsogolo. Mapangidwe a screw, kuphatikizira kukula kwake ndi kutalika kwa m'mimba mwake, amathandizira kwambiri momwe zinthu zimayendera bwino. Dongosolo lowongolera limalola ogwiritsa ntchito kusintha liwiro la screw ndi kuchuluka kwa chakudya, zomwe zimathandiza kukonza bwino ma polima osiyanasiyana.

- Ma feed hopper amapangidwa kuti ateteze kutsekeka ndikuwonetsetsa kudyetsa kosalala.

- Chophimbacho chimatumiza, kukakamiza, ndikuyamba kutentha polima.

- Kuwongolera kutentha mu mbiya kumathandiza kukhathamiritsa njira yosungunuka.

Kafukufuku woyambirira adawonetsa kuti kuwongolera kuthamanga kwa screw ndi kutentha kumakhudza mwachindunji momwe ma polima amadyera ndi kusungunuka. Masiku ano ma laboratory extruder amagwiritsa ntchito njira zotsogola kuti azidyetsa bwino komanso mokhazikika.

Kusungunula ndi Plasticizing

Pamene polima imayenda motsatira mbiya, imalowa m'madera otentha. Kutentha m'dera lililonse kumawonjezeka pang'onopang'ono, kuchititsa kuti polima afewetse ndikusungunuka. Kuzungulira kwa wononga ndi kutentha kwa mbiya zimagwirira ntchito limodzi kuti zisanduke pulasitiki, ndikusandulika kukhala yunifolomu yosungunuka. Zomverera zomwe zimayikidwa pambali pa mbiya zimawunika kutentha ndi kukakamizidwa kuti zitsimikizire kuti polima imasungunuka m'kati mwake momwe imapangidwira.

| Parameter | Kufotokozera |

|---|---|

| Sungunulani Kutentha | Ayenera kukhala mkati mwa ma polima kuti apeze zotsatira zabwino. |

| Kupanikizika Pamwamba pa Screw | Zimasonyeza kusungunula khalidwe ndi ndondomeko bata. |

| Kusinthasintha kwa Mphamvu | Kuyang'aniridwa kuti muwone zovuta zilizonse ndi kusungunuka kapena kuyenda. |

| Kusinthasintha kwa Kutentha | Amatsatiridwa kuti atsimikizire ngakhale kutentha komanso kupewa zolakwika. |

| Digiri ya Kusungunuka | Kufufuzidwa mowoneka kapena kuyesa filimu yotulutsidwa kuti imveke bwino komanso yofanana. |

| Screw Performance Index | Phatikizani zinthu izi kuti muyese kusungunuka kwabwino kuchokera ku kusauka (0) kupita ku zabwino kwambiri (1). |

Kuwongolera molondola kwa kutentha ndi kupanikizika kumathandiza kupewa kuwonongeka ndikuwonetsetsa kusungunuka kosasinthasintha. Kuwunika kwanthawi yeniyeni ndi masensa apamwamba komanso njira zowonera kumapereka chidziwitso chopitilira, kulola ochita kafukufuku kusintha zosintha ngati pakufunika.

Kusakaniza ndi Kutumiza

Akasungunuka, polima ayenera kusakanizidwa bwino kuti atsimikizire kufanana. Mapangidwe a screw, kuphatikiza zinthu monga zotchinga kapena zosakaniza zosakanikirana, zimathandiza kuphatikiza zinthu ndikuchotsa zidutswa zotsalira zotsalira. Pamene wonongayo ikuzungulira, imakankhira polima wosungunula kutsogolo, ndikuifikitsa ku fa.

Ofufuza amagwiritsa ntchito khwekhwe zapamwamba ndisampuli madoko ndi optical detectorskuphunzira momwe zinthuzo zimasakanikirana bwino. Pobaya ma tracers ndikuyesa momwe amafalira, amatha kuwona momwe screw speed ndi geometry zimakhudzira kusakanikirana. Kuthamanga kwakukulu kwa screw nthawi zina kumatha kusiya zidutswa zolimba, koma mapangidwe apadera a screw amathandizira kusakanikirana ndikuletsa nkhaniyi.Masensa apakati pa mbiyakuyeza momwe polima imayendera bwino, kuthandiza ogwira ntchito kukhathamiritsa ntchitoyi.

Kusintha Kudzera mu Die

Polima wosungunuka amafika pakufa, komwe amaupanga kukhala mawonekedwe omwe akufuna. Mapangidwe a difa amatsimikizira kukula kwa chinthu chomaliza ndi mtundu wa pamwamba. Mainjiniya amagwiritsa ntchito zoyerekeza zamakompyuta ndikuwunika komaliza kuti apange mafelemu omwe amapanga mawonekedwe olondola ndikuchepetsa zolakwika. Amathandiziranso mawonekedwe a geometry oyenda kuti azitha kuyendetsa bwino komanso kuchepetsa kusiyana kwa ma cell, zomwe zingakhudze kukula kwa chinthucho.

| Umboni Mbali | Kufotokozera |

|---|---|

| Finite Element Analysis | Amagwiritsidwa ntchito pophunzira kuyenda ndikusintha kulondola mukufa. |

| Kukhathamiritsa Design | Imachepetsa zolakwika ndikuwongolera kulondola kwa geometric. |

| Kutsimikizira Kwakuyesera | Imatsimikizira kuwongolera kwakukulu kwazinthu. |

| Kuyerekezera Nambala | Zolosera kufa kufupika ndi mawonekedwe kayendedwe kwa zotsatira zabwino. |

| Molecular Orientation Control | Miyezo imayenda kuti mupewe kutambasuka kosagwirizana ndi kusintha kwa mawonekedwe. |

Kuwongolera molondola kwa zida zakufa ndi zotsika kumapangitsa kuti chinthucho chichokeSingle Screw Extruderndi mawonekedwe olondola ndi kukula kwake.

Kuziziritsa ndi Kulimbitsa

Pambuyo popanga, polima yotentha imatuluka pakufa ndikulowa mugawo lozizirira. Kuzizira kumalimbitsa polima, kutseka mawonekedwe ake omaliza ndi katundu wake. Kuzizira kumadalira kutentha kwa extrusion, malo ozungulira, ndi liwiro limene mankhwala amadutsa kumalo ozizira.

| Parameter / Mbali | Kuwonera/zotsatira |

|---|---|

| Extrusion kutentha | Polima yotulutsidwa pa 100 ° C |

| Kutentha kozungulira | Imasungidwa pafupifupi 20 ° C panthawi yoyesera |

| Kuzirala mlingo pachimake kutentha | Pafupifupi 72 °C |

| Zotsatira za liwiro | Mayendedwe otsika amachepetsa kuziziritsa ndikuwonjezera nthawi yolimba |

| Kuzizira mlingo khalidwe | Kuthamanga kwakukulu kumatsika pamene liwiro limachepa; kusintha kwakukulu kwa nthawi yayitali |

| Mipikisano wosanjikiza zotsatira | Kenako zigawo zimatha kutenthetsanso zam'mbuyomu, ndikuwongolera kumamatira |

Kusunga madera ozizira mkati mwa kutentha kochepa, nthawi zambiri mkati mwa ± 2°C, kumathandiza kuonetsetsa kuti zinthu zili bwino. Kuziziritsa koyenera kumalepheretsa kugwedezeka ndikuwonetsetsa kuti polima imalimba mofanana.

Kugwiritsa Ntchito Single Screw Extruder mu Polymer Research

Kupanga Zinthu ndi Kuyesa

Ofufuza amagwiritsa ntchito ma extruder a labotale kupanga ndikuyesa mitundu yatsopano ya polima. Maphunziro oyambira ndi ma Patent amafotokoza momwescrew designndi kuwongolera kutentha kumapangitsa kusungunuka ndi kusakanikirana. Kusintha kumeneku kumathandiza asayansi kupanga zida zatsopano zokhala ndi zinthu zinazake. Mwachitsanzo, otsika mphamvu extruder yomangidwa ndi zipangizo m'deralo anasonyeza amphamvu kupanga labu-ang'ono. Idakonzedwa mpaka 13 kg pa ola limodzi ndikuchepetsa zopangira zosafunikira pazomaliza. Zotsatira izi zimatsimikizira kuti ma laboratory extruders amathandizira zonse zatsopano komanso kuwongolera kwabwino pakupanga zinthu.

| Parameter | Mtengo/Zotsatira |

|---|---|

| Kupititsa patsogolo | 13.0 kg/h |

| Liwiro la Screw | 200 rpm |

| Diameter ya mbiya | 40 mm |

| Mlingo Wokulitsa | 1.82–2.98 |

| Kuchepetsa kwa Trypsin Inhibitor | 61.07% -87.93% |

Kukhathamiritsa kwa Njira

Ma extruder a labotale amathandizira asayansi kupeza njira zabwino zosinthira ma polima osiyanasiyana. Deta yoyesera ikuwonetsa zimenezokugwiritsa ntchito mphamvu kumadalira wononga liwiro ndi katundu katundu. Pojambula mphamvu zamagalimoto ndikusintha makonzedwe, ofufuza amatha kuwongolera mphamvu zamagetsi komanso mtundu wazinthu. Kafukufuku amasonyezanso kuti kusinthascrew liwirondi kuwonjezera zinthu zina zimatha kusintha momwe ma polima amasakanikirana ndikuyenda. Zomwe zapezazi zimathandiza magulu kuti akhazikitse njira zotetezeka, zogwira mtima komanso zobwerezabwereza pofufuza ndi kupanga.

Langizo: Kusintha liwiro la screw ndi kutentha kumatha kulinganiza kugwiritsa ntchito mphamvu ndikuwongolera mtundu wazinthu.

Pang'ono-pang'ono Product Prototyping

Lab extruder imapangitsa kukhala kosavuta kupanga magulu ang'onoang'ono azinthu zatsopano. Magulu amatha kuwongolera kutentha, kupanikizika, ndi liwiro la screw kuti apeze zotsatira zodalirika. Njirayi imapulumutsa ndalama ndikufulumizitsa chitukuko. Ofufuza amatha kuyesa malingaliro atsopano mwachangu ndikukulitsa opambana. Ma compact extruder amalolanso kusintha kosinthika kwazinthu kapena kapangidwe. Kupita patsogolo kwa makina ochita kupanga komanso kuyang'anira nthawi yeniyeni kumapangitsanso kuwongolera ndikuchepetsa zinyalala.

- Kuwongolera kolondola pa magawo a ndondomeko

- Zotsika mtengo komanso mwachangu ma prototyping

- Kusintha kosavuta kwa zida zosiyanasiyana

- Kupititsa patsogolo ubwino wa mankhwala ndi kufanana

Malangizo Ogwirira Ntchito ndi Kuthetsa Mavuto kwa Single Screw Extruder

Kupanga Extruder

Kukonzekera koyenera kumatsimikizira kugwira ntchito kodalirika ndikuwonjezera moyo wa zida. Amisiri amatsatira izimasitepe ochita bwino kwambiri:

- Ikani zomangiram'malo awo oyambirira ndikuyesa zomangira zatsopano pa liwiro lotsika musanagwire ntchito yonse.

- Sinthanikuwongolera kutenthazida nthawi zonse zosintha zolondola.

- Gwiritsani ntchito madzi osungunula mu thanki yozizira kuti musachuluke ndikuwunika kuchuluka kwa madzi nthawi zambiri.

- Yang'anani mavavu a solenoid ndi zozungulira, ndikuchotsa mbali zilizonse zolakwika.

- Tetezani ma couplers tsiku ndi tsiku ndikuwonetsetsa kuti mawotchi otenthetsera ndi ma valve solenoid amagwira ntchito moyenera.

- Tsukani matanki a vacuum ndi zipinda zotulutsa mpweya; sinthani mphete zomata zotha ngati pakufunika.

- Yang'anani maburashi amagalimoto a DC ndikuteteza ku dzimbiri.

- Preheat pang'onopang'ono poyambira ndikuwonjezera liwiro la screw pang'onopang'ono.

- Mafuta osuntha mbali ndi kumangitsa zomangira nthawi zonse.

- Kuti musunge nthawi yayitali, ikani mafuta oletsa dzimbiri ndikusunga zomangira moyenera.

Langizo: Kutsatira izi kumathandiza kuti zinthu zikhale bwino komanso kuti zida zizikhala ndi moyo wautali.

Mavuto Wamba ndi Mayankho

Othandizira amatha kukumana ndi zovuta zingapo panthawi yogwira ntchito. Tebulo ili m'munsiyi ikuwonetsa mavuto omwe anthu ambiri amakumana nawo ndi mayankho ake:

| Gulu la Nkhani | Mavuto Ambiri | Zoyambitsa | Zizindikiro | Zothetsera |

|---|---|---|---|---|

| Kulephera Kwamakina | Screw wakamira | Kuchuluka kwa zinthu, kusakaniza bwino | Kudzaza kwa injini, phokoso | Oyera, mafuta, fufuzani |

| Kulephera kwa Magetsi | Kulephera kwa injini | Kutentha kwambiri, dera lalifupi | Osayamba, kutenthedwa | Yang'anani dongosolo, pewani kuchulukirachulukira |

| Kulephera kwa Njira | Kusauka kwa pulasitiki | Kuthamanga kochepa, kutentha kolakwika | Pamwamba, thovu | Sinthani liwiro, kutentha, zinthu |

| Njira Zopewera | Kusamalira | Kupanda kuyeretsa, kuyang'anitsitsa | N / A | Kuyeretsa ndandanda, kuyendera |

Kuyendera ndi kukonza nthawi zonse kumalepheretsa zovuta zambiri. Othandizira ayenera kutsatira malangizo a pamanja posintha ma extrusion kufa kuti apewe zolakwika.

Zolinga Zachitetezo

Laboratory extruder ntchito kumaphatikizapo zoopsa zingapo. Njira zachitetezo zikuphatikiza:

- Kuvala zida zodzitetezera ngati nsapato ndi magalasi.

- Kupewa zovala zotayirira pafupi ndi zosuntha.

- Kuyika zida zonse zamagetsi ndi anthu oyenerera.

- Kusunga pansi pouma ndikugwiritsa ntchito nsanja kapena ngalande kuti muteteze kutsetsereka.

- Kuika alonda pazigawo zosuntha kuteteza manja.

- Kugwiritsa ntchito mizere yoyambira polumikizira m'malo modyetsa pamanja.

Chidziwitso: Kusamala kwambiri zachitetezo kumachepetsa chiopsezo cha kupsa, kugwedezeka kwamagetsi, komanso kuvulala pamakina.

Laboratory extruders amathandizira otetezeka, kothandiza polima processing kudzerakuwongolera bwino kutentha, kuthamanga, ndi liwiro la wononga. Ochita kafukufuku amapindula ndi kupanga magulu ang'onoang'ono, kuchepetsa zinyalala, komanso kufotokoza mofulumira. Mapangidwe a modular amathandizira kusintha mwachangu ndikusintha mwamakonda. Kuchita mosasinthasintha komanso kusamala mwatsatanetsatane kumathandizira kupeza zotsatira zodalirika komanso kulimbikitsa luso lazofufuza za polima.

FAQ

Kodi ma polima angathe labotale single wononga extruder ndondomeko?

A laboratory single screw extruderamatha kukonza ma thermoplastics ambiri, kuphatikiza polyethylene, polypropylene, polystyrene, ndi PVC. Ofufuza nthawi zambiri amasankha zipangizo malinga ndi zofunikira za polojekiti.

Kodi kutulutsa mpweya kumakweza bwanji mtundu wa polima?

Kutulutsa mpweya kumachotsa chinyezindi mpweya wochokera ku polima umasungunuka. Izi zimalepheretsa kuwonongeka, monga kuwira kapena mawanga ofooka, ndikuwongolera mawonekedwe a chinthu chomaliza.

Kodi ogwira ntchito amawongolera bwanji kutentha kwa extrusion?

Oyendetsa amaika ndi kuyang'anira kutentha kwa migolo pogwiritsa ntchito makina owongolera. Zomverera zimapereka ndemanga zenizeni zenizeni, kulola kusintha kolondola kwa kusungunuka kwa polima ndi mawonekedwe.

Nthawi yotumiza: Jul-01-2025